Chebureki

Chebureki Machine and Production Solution

Model no : SOL-CBK-0-1

Chebureki, also known as Raw Borek, is a type of deep-fried meat-filled turnover originating in Eastern Europe; it is sold as a popular street food in Turkey and Ukraine. There is a similar product called “Pirozhki” that is widely consumed in Eastern European regions; usually, Chebureki and Pirozhiki are sold in cafes and restaurants as regular items on the menu. Many local food manufacturers in Eastern European countries are producing ready-to-cook frozen Chebureki that can be easily microwaved and served; it is a product in high demand and can be purchased from online stores and e-commerce platforms. Please click on the link below and complete the form to receive an initial quotation, and our professional consultants will assist you.

Professional Chebureki Production Plant Planner

Chebureki is made similarly to Empanada, and the filling is primarily made of chopped onions, ground beef, or lamb. The pastry is usually made as thin as 1.5mm, and each Chebureki usually weighs 100-120g and then is formed into half-moon-shaped pastries.

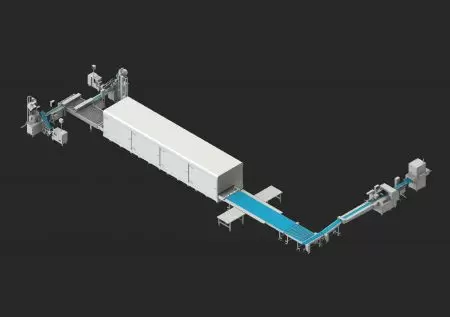

ANKO recommends our HLT-700 Series Multipurpose Filling and Forming Machine for producing Chebureki; it can produce products as large as 100g per piece at a capacity of 2,000 to 20,000 pieces per hour. If you are interested in customizing your products into different sizes and shapes, please feel free to contact us for more information. ANKO offers many Chebureki production solutions, including configuring food prep mixers, meat grinders, forming machines, deep-fryers, and packaging equipment. We can customize your Chebureki production line to accommodate your specific product requirements and grow with your existing operations.

HLT-700U has a built-in Internet of Things (IoT) system which is connected to the Big Data Analytics. It collects data from each production and be utilized with extended applications to manage production balances, warehousing and scheduling. This technology offers you full control over production by “monitoring the machine operational status, maintenance machine lifespan, and digital production management”. An alarm will inform you the exact part that needs inspection to reduce any possible risks.

1

Filling / Forming

- Forming

Case Studies

EMP-900 Machine – Designed for producing Empanadas made with high fat content dough

ANKO has been approached by many companies and clients seeking a machine that can process high fat content dough…

Automatic Layered Paratha Production Line for a Bangladeshi Company

The client decided to run a paratha production line due to the popularity of paratha. He trusted ANKO with Turnkey Planning Consulting Services...

Automatic Samosa Pastry Sheet Machine– Machinery Design for Kuwait Company

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one…

Sambousek Automatic Production Equipment Designed with a Customized Half-moon Rotary Mold

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products…

Semi-Automatic Blini Production Equipment Designed with Soft Pancake Stacker

Our agent gave a test run with ANKO's SRP for making blini, but failed to arrange them in a pile. Thus, ANKO's engineers developed…

Stuffed Cassava Ball Machinery Design for a Peruvian Company

The client's stuffed cassava products had been made by hand. When the demand increased to a certain amount, he was seeking a machine…

Paneer Spring Roll Automatic Production Equipment Designed with Special Filling Device

Years ago, the client bought SR-24 spring roll machine from ANKO. This time, he placed another order because he trusts ANKO…

The Best Selection - Get Started with Us to Discuss Your Needs

Multipurpose Filling and Forming Machine

ANKO’s most powerful Dumpling Machine, the “HLT-700U Multipurpose Filling and Forming Machine” is integrated with a new filling system! It can process large pieces of food ingredients, less oil, and high roughage fillings, as well as cooked meats that are less viscous. Not only it can handle a wide range of ingredients, but it can also produce dumplings that are plump and look handmade. This machine is compact in size (less than 1.5 square meters) and when forming dumplings at 25g per piece, it has the capacity of producing 12,000 pieces per hour. It is suitable for independently owned restaurants and large food factories. The IoT (Internet of Things) have been installed to ensure that the production can be overseen by managers in real time on a mobile device, and the data can be collected and processed through Big Data Analytics to support decision making. We have also installed a maintenance reminder program to ensure consistent productivity. Please click on the link below to fill out the form and our sales professionals will get back to you with customized solutions for your food production specifications.

More Info Compare searies machineCompare with Similar Models

| Model no | Multipurpose Filling and Forming Machine HLT-700U | Multipurpose Filling and Forming Machine HLT-700XL | Double-Line Multipurpose Filling and Forming Machine HLT-700DL |

|---|---|---|---|

| Description | Tasty Appearance as handmade look | A wide range of standard rotary molds are available | Highest production capacity |

| Capacity | 2,000 - 12,000 pcs/hr | 2,000 - 10,000 pcs/hr | 4,000 - 20,000 pcs/hr |

| Weight | 13 - 100 g/pc | 13 - 100 g/pc | 13 - 100 g/pc |

| More Info | More Info | More Info |

Specifications

Capacity: 12,000 pcs/hr or 250 kg/hr

Features

- The built-in IoT function integrates the automated production line, and you can access this through remote monitoring via ANKO’s IoT dashboard.

- Voltage can be designated.

- The thickness of chebureki wrapper and the amount of filling can be adjusted by parameter setting.

- The shape of chebureki can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

Would you like to find machines or integrated production line?

- Downloads

- Best Selling

- Related Food Solutions Type