ANKO Food Lab Reveals: Three Key Technologies for Mass-Producing Gluten-Free Dumplings

09 Feb, 2026Global demand for gluten-free food continues to grow, driving brands to seek reliable gluten-free dumpling production solutions. When replacing wheat flour with rice flour, many food manufacturers face challenges such as low dough elasticity, frequent tearing, and limited scalability. These technical barriers make gluten-free dumplings difficult to commercialize. ANKO Food Lab has developed a gluten-free dumpling formula and automated production solution that improves dough structure and production stability, helping food manufacturers capture fast-growing gluten-free market opportunities.

What Are the Biggest Technical Challenges in Gluten-Free Dumpling Production?

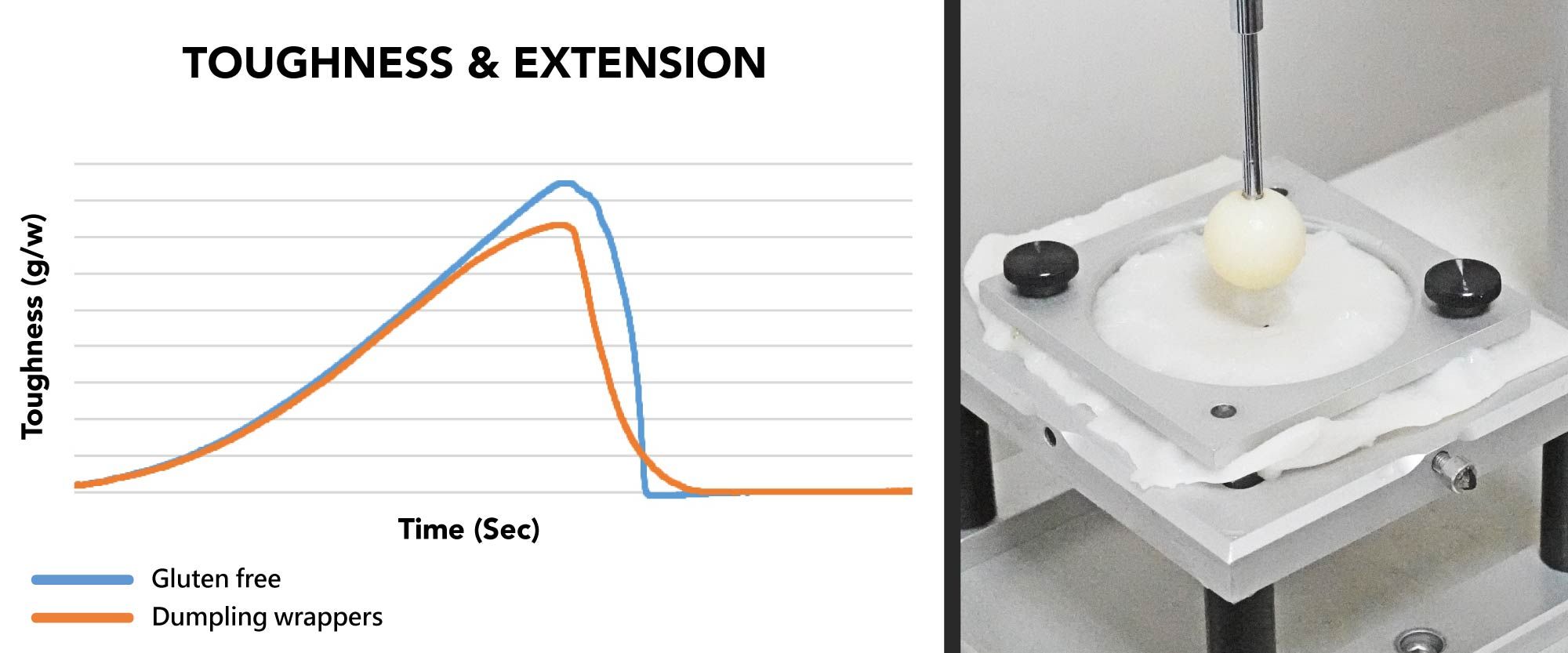

Gluten-containing dough forms a network structure that provides elasticity, extensibility, and pressure resistance, making it suitable for high-speed stuffing and mass production. In contrast, gluten-free dough faces three major challenges:

1. Lack of elasticity and extensibility: Dough is difficult to stretch and easily breaks or shrinks under pressure.

2. Low forming stability: Wrappers tend to tear during high-speed stuffing or rolling processes.

3. Moisture retention and texture issues: Wrappers dry out easily, have poor chewiness, or break apart after cooking.

On standardized production lines, these issues lead to reduced output and increased costs, becoming the main technical barrier to large-scale gluten-free dumpling production.

How to Improve Elasticity and Cooking Resistance in Gluten-Free Dough?

To overcome structural limitations of gluten-free dough, ANKO Food Lab uses rice flour as the primary base and applies three core technologies to enhance wrapper strength:

1. Ingredient selection: Using low-viscosity rice flour to reduce gelatinization stickiness and improve processing stability.

2. Pre-treatment technology: Controlling water temperature and gelatinization to create dough with improved elasticity and binding performance. Studies show properly treated rice flour can partially replicate gluten-like structural support.

3. Formula optimization: Adding starch in precise proportions to reinforce dough structure, improving cooking resistance and texture.

Tested on the HLT-700U Multipurpose Filling and Forming Machine, this formula withstands auger pressure, maintains sealing integrity, and prevents wrapper breakage after cooking—meeting commercial mass production requirements for gluten-free dumplings.

Why Are Stuffed Foods a High-Potential Opportunity in the Gluten-Free Market?

In 2024, the global gluten-free food market exceeded USD 7.75 billion, growing at an annual rate of approximately 10%, with baked goods as the fastest-growing segment. However, while the gluten-free market is expanding, Asian stuffed foods remain underdeveloped, as most products focus on bread, cookies, and pizza. Gluten-free dumplings that achieve stable shaping and traditional wrapper texture are still rare.

Because wrapper-based products require high elasticity and toughness, technical barriers are higher—but once overcome, competition remains limited. This makes gluten-free dumplings a strategic category for food manufacturers seeking market differentiation. ANKO’s gluten-free dumpling formula and mass production solution are designed to help brands enter this underserved market ahead of competitors.

Want to Test Whether Your Gluten-Free Dumplings Are Ready for Mass Production? Book a Trial with ANKO

For businesses developing gluten-free dumplings, ANKO offers customized gluten-free formulas, machine trial testing, and product tasting services. Schedule a test run today and let ANKO help you achieve a three-way success: commercial scalability, great taste, and compliant labeling.

Source: Research Gate、Global Market Insights、National Library of Medicine