Double-Line Multipurpose Filling and Forming Machine

Automatic Pasta Forming Machine

Model no : HLT-700DL

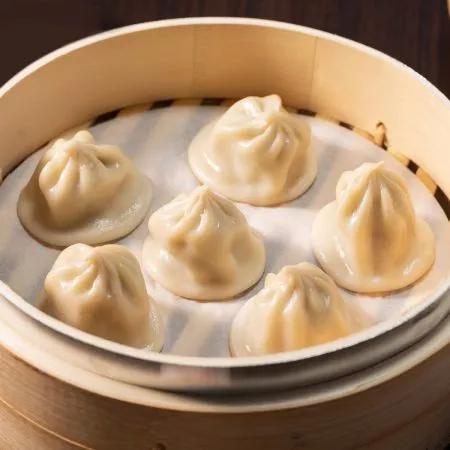

The HLT-700DL Double Line Multipurpose Filling & Forming Machine has a stable filling system and two forming mold sets to increase production capacity to 60,000 pcs/hr. Compared with the single-line machine model, the number has doubled without compromising quality. With the easy-change forming mold sets, tens of products can be made with one machine, such as dumpling, potsticker, samosa, har gow, ravioli, etc. Want to get a quick quote and consultant? Please click the button below and fill out the form.

How It Works

Food's Gallery

- Half Moon

- Rectangular

- Square

- Pelmeni

- Half Moon

- Triangle

Optional Accessories

Standard mold, CE kit

Shape

| Shape | Semi Circle | Triangle | Square | Circle | Pleat | Rectangle |

| Demo |  |  |  |  |  |  |

| Length | 15-200 mm | 60-120 mm | 35-80 mm | Dia.30-65 mm | 45-55 mm | 35-80 mm |

| Width | 10-100 mm | 50-85 mm | 35-80 mm | Dia.30-65 mm | 30-35 mm | 30-45 mm |

Pattern

| Without Pattern | Semicircle Pattern | Shell Pattern | Nail Pattern | Ladder Pattern |

|  |  |  |  |

In addition, we also provide Mold Customization, please click, click Learn More>

Specifications

- Dimensions: 1,580 (L) x 840 (W) x 1,720 (H) mm

- Power: 6.5 kW

- Capacity: 4,000–20,000 pcs/hr

- Product name: Dumpling, Potsticker, Fried leek dumpling, Curry puff, Noodle, Roll, Pie

- Product weight: 13–100 g/pc

- Optional accessories: Standard mold, CE kit

- Weight (net): 900 kg

- Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

-

Suitable for different kinds of dough.Including dough with 30% - 50% hydration which made with cold, warm, or hot water, and dough with up to 20% shortening content.

-

Suitable for a wide variety of filling.Including cheese, vegetables, and dices of shrimp, meat, and cooked potato.

- High production capacity.

- Equipped with a water cooling system to prevent dough from degradation caused by heat.

- The error message will display on the screen for operators to troubleshoot more quickly.

- Operators can store and access 9 groups of parameter settings for easy operation.

- Two forming mold sets can work individually to adjust production capacity flexibly or to make food in different shapes (under certain conditions).

- Filling hopper is easy to disassemble for cleaning. The thickness of wrapper and quantity of filling are adjustable.

Case Studies

Dumpling Production Equipment Helps to Increase Capacity and Standardize Products

Using a dumpling maker can both improve capacity and achieve standardization. Therefore, the client chose ANKO as the solution provider…

Automatic Har Gow Machinery Design for a Dutch Company

In order to increase productivity, the client was looking for professional food machine supplier. They heard that ANKO manufactured high quality Har Gow machine…

Sambousek Automatic Production Equipment Designed with a Customized Half-moon Rotary Mold

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products online…

Soup Dumping Automatic Production Equipment Designed to Solve Insufficient Capacity and Product Quality

The company owns a Cantonese restaurant serving handmade dim sum. With business growth, a lack of supply…

Multipurpose Filling & Forming Machine - Machinery Design for Taiwanese Company

Potsticker is popular in Great China area, so the supply was often unable to meet the demand. Thus, the client decided to manufacture with machine…

Fried Apple Pie Making Machine – Machinery Design for Panamanian Company

The client has run Korean restaurants in Panama, where are viewed by local people as a good place to satisfy your taste…

Xiao Long Bao Making Machine - Machinery Design for Dutch Company

The client started his business by opening a restaurant in Netherlands, serving dim sum dishes. He studied the Dutch flavor and healthy…

Compare models

| Model no | Double-Line Multipurpose Filling and Forming Machine HLT-700DL | Multipurpose Filling and Forming Machine HLT-700U | Multipurpose Filling and Forming Machine HLT-700XL |

|---|---|---|---|

| Description | Highest production capacity | Tasty Appearance as handmade look | A wide range of standard rotary molds are available |

| Capacity | 4,000 - 20,000 pcs/hr | 2,000 - 12,000 pcs/hr | 2,000 - 10,000 pcs/hr |

| Weight | 13 - 100 g/pc | 13 - 100 g/pc | 13 - 100 g/pc |

| More Info | More Info | More Info |

Certification No.

- Taiwan Patent No.M509541

- Downloads

- Best Selling

FAQ

Double-Line Multipurpose Filling and Forming Machine are worth the investment for food manufacturing companies, restaurants, and frozen food manufacturers. The HLT-700DL helps reduce labor costs, increase production capacity, and maintain consistent product quality, making it far more efficient than manual production. Many businesses have scaled from small shops or food carts to large chain restaurants with the support of ANKO’s machines, proving their long-term value in business growth.

Yes. Purchasing food machinery includes full service before and after installation. We provide machine testing, product trial runs, and consultation through local offices and distributors worldwide, including the US, Europe, and Asia. After purchase, buyers receive installation, operator training, and after-sales service to ensure stable production. In addition, modular and partially customized options allow manufacturers to adjust machine settings to create different product textures, shapes, and flavors efficiently.

Double-Line Multipurpose Filling and Forming Machine prices vary depending on capacity, automation level, and customization options. The HLT-700DL can be integrated with upstream vegetable cutting and dough mixing equipment, as well as downstream steaming or freezing systems to meet full production line needs. While mid-to-large commercial dumpling machines require higher investment, they significantly reduce labor costs and ensure consistent output. With just two steps to change attachments, the HLT-700DL can produce multiple food shapes, such as dumplings and ravioli, making it ideal for manufacturers seeking efficiency and product variety.