Integrated Plain Paratha Production Line

Model no : SOL-PPT-T-1

ANKO’s Integrated Plain Paratha Production Line is designed for high-quality, multi-layer flatbreads. By loading dough and butter into the hopper, the line fully automates pressing, oil-layer folding, rolling, shaping, and flattening—no manual work required. With a film-pressing system, it can produce up to 32-layer round parathas, then automatically film and stack them. The full line connects 11 stations, including dough feeding, forming, aligning, filming, packaging, weight checking, freezing, metal detection, robotic picking, and carton sealing, plus environmental monitoring. With production capacity reaching up to 10,800 pieces per hour, this solution is ideal for frozen flatbread manufacturers and global food factories seeking stable, high-speed production with reduced labor.

1

front-end

- ①Dough Feeding System

①Dough Feeding System

An Automatic Separate Mixer handles up to 150 kg of flour per batch, reducing prep workload and improving efficiency. Paired with a Bowl Lifter, the dough is safely raised to feeding height and directly transferred to the next stage—minimizing manual labor and contamination risk. This setup ensures steady dough supply and consistent quality for pressing and baking.

2

mid-section

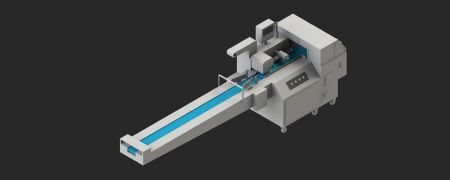

- ②Automatic Layer & Stuffed Paratha Production Line

②Automatic Layer & Stuffed Paratha Production Line

The Automatic Layer & Stuffed Paratha Production Line simulates the traditional handmade process. From folding with oil, rolling, wrapping, to dough ball forming, each step replicates manual techniques, ultimately producing up to 32-layer parathas with a texture that rivals handmade quality.

3

back-end

- ③Automatic Aligning And Rack Loading Machine

- ④Automatic Filming And Pressing Machine

- ⑤Packaging Device

- ⑦IQF / Freezer

- ⑨Delta Robot

- ➉Carton Sealer

4

quality control

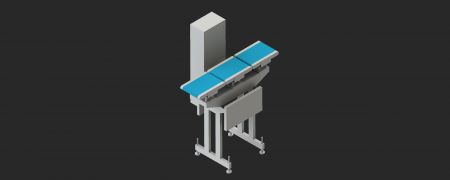

- ⑥Weight Inspection

- ⑧Metal Detector

- ⑪Environmental Monitoring

⑪Environmental Monitoring

Combining temperature and humidity monitoring with smart management, users can customize alert thresholds. When data exceeds the set range, instant mobile notifications are sent to reduce losses and enhance management efficiency. It also provides environmental data analysis and historical reporting features, enabling a high level of facility condition monitoring. ※Limited to regional sales

Features

-

Ultra-high production capacity configurationANKO customizes the integrated Plain Paratha production line to meet your specific production capacity and product requirements.

-

Modularized Production ComponentsThe integrated Plain Paratha production line consists of various components. ANKO can integrate various options for feeding equipment, forming machines, automatic aligning devices, quality inspection machines, and cooking equipment into an existing production line configuration.

-

Construction of highly automated factoriesThe integrated Plain Paratha production line improves overall production efficiency, and significantly reduces labor requirements and cost. Giving you competitive advantages.

-

Ensure quality, health, and food safetyA fully automated production line with feeding equipment, conveyor belts, automatic aligning and rack loading machines, plays a crucial role in reducing human error. This, in turn, significantly reduces hazards caused by artificial contaminants ensuring high quality Plain Paratha production, and greater overall food safety.

-

Gain Complete Control Over Environmental ChangesCombining intelligent temperature and humidity monitoring with efficient management, the professional team at Fox-Tech offers comprehensive solutions. For assistance, please contact: service@fox-tech.co or visit the Fox-Tech website.

- Best Selling