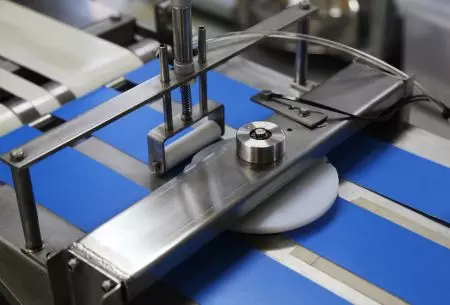

Dough Mixer

High Speed Dough Mixer

Model no : ML Series

The Dough Mixer is your best choice to mix dough. After putting ingredients into the mixing bowl, the mixer mixes them at a required speed. Dough hook, whisk, and flat beater are included to enable you to utilize them based on different consistencies of dough. Want to get a quick quote and consultant? Please click the button below and fill out the form.

How It Works

Specifications

| Model No. | ML-22 | ML-202E |

|---|---|---|

| Dimensions | 820 (L) x 700 (W) x 1,340 (H) mm | 1,090 (L) x 670 (W) x 1,140 (H) mm |

| Power | 2.25 kW | 5.1 kW |

| Capacity | approx. 22 kg flour | approx. 50 kg flour |

| Including two bowls, a hook, a whisk, a beater and a castor | ||

| Weight (net) | 400 kg | 370 kg |

| Weight (gross) | 450 kg | 470 kg |

Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

- Suitable for mixing dough.

- Butter and moisture content below 75%.

- 2 speed levels available.

- Two-way rotary bowl can knead, rub, pinch, mix, twist and roll dough like hand gestures.

- Quickly accomplish stirring task.

- Made by stainless steel.

- Include mesh safety cover and dough hook, beater, and whisk.

- Comply with hygiene regulations and suitable for restaurants and small factories.

Case Studies

Chinese Shumai Production Line Design for a Hong Kong Company

With increasing restaurant business, the owner of a dim sum restaurant would like to expand his production capacity with with the tight kitchen space....

Kibe Automatic Production Equipment Designed for a French Company

Kibe (Kibbeh) is one of the basic cuisines in the Middle East, so the high demand has made client's business booming. However, his employees couldn't meet…

ANKO Japanese Manju Production Line - Machinery Design For a Japanese Company

This company owns a bakery, selling various buns and bread. Brown sugar is a common ingredient in Asian cooking…

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

High Quality Wonton Production Line for a British Company

Wonton wrapper retains less water and higher gluten. If tongs pull too strong, the dough belt may be torn off. To prevent…

Spring Roll Production Line for a US Company to Grow Food Business

Since client's business grew, he would like to increase productivity and improve the looks of products. He had been looking for a better solution…

- Downloads

- Best Selling