Wonton

Your Wonton Production Planning And Wonton Recipe Consultant.

Model no : SOL-WTN-S-1

ANKO's "automatic wonton production solution" gives comprehensive support from equipment to service. ANKO offers every customer "one-stop" consulting services including machines and recipe adjustment. We set up your own production line from ingredient preparing, food producing, to packaging machine, according to your conditions and production capacity. You can not only buy all machines once, but also get advices about purchase, production, package, and go-to market strategy from ANKO's professionals with years of accumulated experience and knowledge. In the solution below, the machines can be adjusted in model and quantity according to real production needs. Want to get a quick quote and consultant? Please click the button below and fill out the form.

About Wonton Production Solution

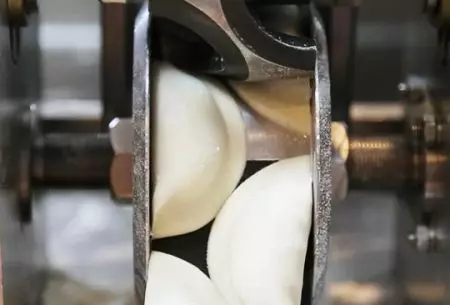

ANKO HWT-400 Automatic Double-line Wonton Machine, which is capable of producing regular or larger wontons of product weight from 12 g-17 g/pc, productivity up to 3,000-4,200 pcs/hr, and the thickness of the wrapper is adjustable; by placing the pre-mixed dough and desired filling in the loading tanks, both machines are capable of producing wonton with great shape and textures. The automatic pressing, pulling, cutting, filling and forming devices, complete the product line without any extra conveyer belt for the dough, and the special forming mold creates folds that resemble handmade products. The actual sizes of the machines are compact and easy to clean.

The HWT-400 has a built-in Internet of Things (IoT) system which is connected to the Big Data Analytics. It collects data from each production and be utilized with extended applications to manage production balances, warehousing and scheduling. This technology offers you full control over production by “monitoring the machine operational status, maintenance machine lifespan, and digital production management”. An alarm will inform you the exact part that needs inspection to reduce any possible risks.

Food's Gallery

- Wonton is firmly filled with meat filling

- The formation remain intact after deep frying

- Wontons remain intact after boiling

- Simulating hand-pinched sealing marks

- Tightly sealed Wontons

- Wontons are fully filled in thin wrappers

- Deep-fried directly with a fryer at the end of the production line

- Wontons boil well and do not fall apart easily

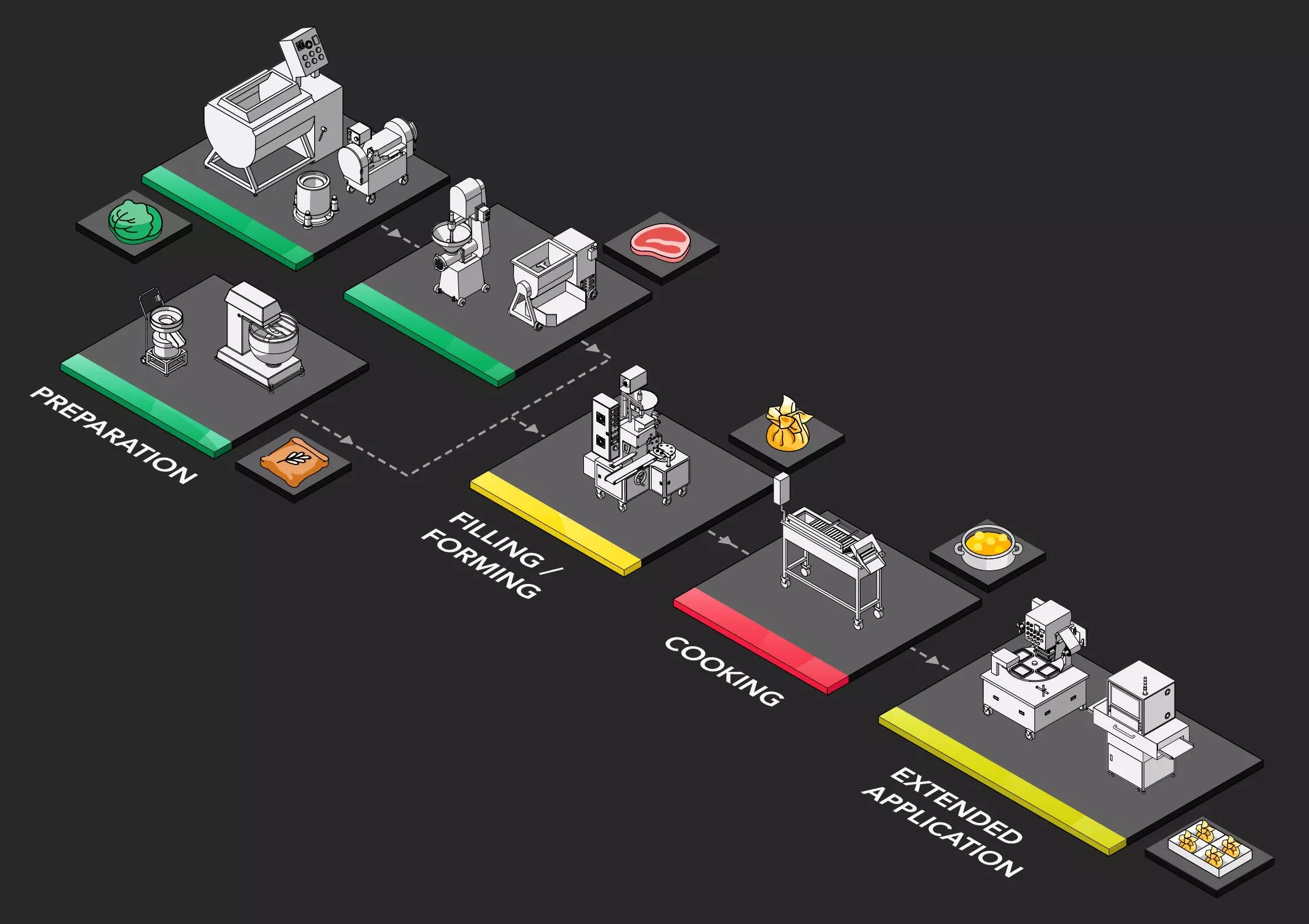

Turnkey and Production Planning

1

Preparation

- Sieving

- Mixing

- Vegetable Cleaning

- Vegetable Cutting

- Extracting

- Meat Mincing

- Seasoning

2

Filling / Forming

- Forming

3

Cooking

- Frying

4

Extended Application

- Sealing

Sealing

The packing machine is included in the solution to pack products fast and smoothly and enable you to quickly deliver them to every channel. If you need other machines, such as aligning machine, steamer, and freezer. ANKO's sales engineers can provide the most practical and affordable solution depending on your needs.

- Quality Control

Quality Control

ANKO’s X-Ray Inspection Machine can detect various metals, bones, glass, and other foreign objects during food production; even something as small as 0.4mm. The machine is equipped with luminating and buzzer warnings to ensure real-time contaminant detection, prevent artificial hazards, and increase overall product quality.

Case Studies

Automatic Wonton Machinery Design for a Canadian Company

With the growing number of branch stores, the client has to prepare more and more pieces of wonton every day. Therefore, they start to…

Automatic Wonton Production Line Design for a British Company

The client combined machine-made and hand-made processes, which turned the impression of uninteresting products made by machines…

Shanghai Wonton Machine Design to Solve Labor Shortage

ANKO customized two rotary molds to help the client mass-produce shanghai wontons that were complicated to fold by hand…

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

In Taiwan, most traditional noodle machines have good productivity but are limited in the types of noodles…

Vegetarian Dumpling Machine for Taiwanese Company

Vegetarian foods are the client's primary products. The manual production no longer meets the growing demands, thus…

Soup Dumping Automatic Production Equipment Designed to Solve Insufficient Capacity and Product Quality

The company owns a Cantonese restaurant serving handmade dim sum. With business growth, a lack of supply…

ANKO Japanese Manju Production Line - Machinery Design For a Japanese Company

This company owns a bakery, selling various buns and bread. Brown sugar is a common ingredient in Asian cooking…

The Best Selection - Get Started with Us to Discuss Your Needs

Automatic Wonton Machine

Automatic Wonton Machine completes the process of making wonton after putting in prepared dough and stuffing. The texture of stuffing stays the same from beginning to end; the pinched pattern on top is as beautiful as hand-made one. The final products show that ANKO is highly concerned with quality control. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More InfoSpecifications

Capacity:48 kg/hr or 4,000 pc/hr

*Based on 12-gram wonton

Features

- The built-in IoT function integrates the automated production line, and you can access this through remote monitoring via ANKO’s IoT dashboard.

- Voltage can be designated.

- Deep-fryer can be equipped with either long or short conveyor.

- Vegetable cutter can julienne, slice, dice vegetables.

- The thickness of wonton wrapper and the amount of filling can be adjusted by parameter setting.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

What services and benefits are covered in the solution?

Want to expand wonton business? Let ANKO, a food machinery expert, do you a favor

Unfamiliar with wonton production line? No experience in production planning? Worried consulting wonton machine suppliers waste too much time or there is no training and reliable after-sales service? You can rest assured that ANKO, 45 years in the field, will handle your concerns. In order to resolve the difficulties that customers across the world have when purchasing, ANKO provides comprehensive "one-stop" service – front- and back-end equipment configuration, turnkey project planning, machine trial, and installation and training. ANKO's consultants have been praised by customers from 113 countries and are ready to assist you in improving performance and expanding unlimited business.

ANKO provides industry-leading integrated services in wonton machines

ANKO's consulting team can help you compare different models to find the most appropriate wonton machine and install an affordable production line based on your needs and required production capacity. Also, we provide exclusive assessment and integration suggestions according to current conditions, workflow, factory layout, estimated time to put machine into operation, recipes, and other issues. The integrated and specialist service can greatly reduce the risk of purchase and, to meet your requirements, give you the best solution to keep smooth operation anytime.

One specialist solving all your problems, making wonton machine repair easy and painless

If your wonton production line consists of machines from different suppliers, when they need to be repaired, it will be troublesome and time-consuming. In the long term, a burden of management will increase. ANKO supplies all kinds of wonton production facilities and comprehensive after-sales services. Even though the facilities and services cover a wide range from ingredient preparing, food forming, cooking, and packing machines as well as repair consultancy and service, all can be handled by one specialist to make machine repair and maintenance easy and painless.

Food consultants with 45 years of experience help you with your wonton recipe

With 45 years of experience in the food machine industry, a wealth of market information, and detailed observation of the industry, ANKO can provide suggestions for equipment upgrades. Through direct interaction with our customers from 113 countries, we are well acquainted with the world's wontons and other related foods as well as consumer preferences. Whether it is about texture or taste, ANKO can offer advices on your recipes, even production and strategy in your target market with our general knowledge.

- Best Selling

- Related Food Solutions Type