Automatic Wonton Machine

Wonton Maker

Model no : HWT-400

Automatic Wonton Machine completes the process of making wonton after putting in prepared dough and stuffing. The texture of stuffing stays the same from beginning to end; the pinched pattern on top is as beautiful as hand-made one. The final products show that ANKO is highly concerned with quality control. Want to get a quick quote and consultant? Please click the button below and fill out the form.

How It Works

Food's Gallery

- Thin wonton wrappers

- Wontons are delicate and delicious

- Wontons filling is densely packed

- Deep fried wontons

- Wontons shaped like handmade

- Tightly clamped and sealed wontons

Optional Accessories

CE kitSpecifications

- Type: Double line

- Dimensions: 1,500 (L) x 1,250 (W) x 1,970 (H) mm

- Power: 3.3 kW

- Capacity: 3,000–4,200 pc/hr

- Product name: Wonton

- Product dimension: 30 (Dia.) x 21 (H) mm

- Product weight: 12–17 g/pc

- Dough belt:Width: 95 mmThickness: 0.3–0.5 mm

- Weight (net): 760 kg

Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

-

The Built-in IoT SystemYou can now sign up and log on ANKO’s IoT website to monitor and manage your food production with integrated food production technology. All the manufacturing data and the production yield rate is collected daily and analyzed via Big Data to provide you with cost-effective suggestions for making your production line more effective.

-

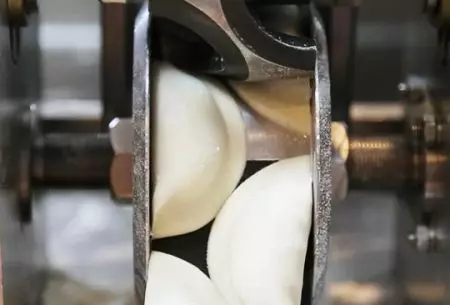

Automatic designPutting well-kneaded dough and filling into the hoppers, after switching on machine, it will make dough pastry wrapper by pressing, pulling and cutting, stuffing filling, forming and sending the products to the conveyor automatically. It keeps the taste as good as handmade.

-

Easy for assemblingModular pressing roller makes assembly, disassembly and maintenance easier. Operators can change it by their own within half an hour.

-

Advanced water resistanceWater resistance enhanced by upgrading rubber seals and making it exactly fit the machine cabinet frames.

-

Uniform products and high capacityThickness of wrapper and weight of stuffing are adjustable.Distance between wonton is adjustable in order to facilitate manual packaging

- Require little space for production.

- ANKO follows Hygiene Policies and Procedures, all the parts in contact with food are made of food standard stainless steel and acrylic.

Case Studies

Won Ton Machinery Design for Canadian Company

Locals prefer ordering out or taking away food so as to save time. Ready-meal is also a choice for many families…

Wonton Production Line for British Company

Wonton wrapper retains less water and higher gluten. If tongs pull too strong…

Shanghai Wonton Machine Design to Solve Labor Shortage

ANKO customized two rotary molds to help the client mass-produce shanghai wontons that were complicated to fold by hand…

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

In Taiwan, most traditional noodle machines have good productivity but are limited in the types of noodles…

Vegetarian Dumpling Machine for Taiwanese Company

Vegetarian foods are the client's primary products. The manual production no longer meets the growing demands, thus…

Soup Dumping Automatic Production Equipment Designed to Solve Insufficient Capacity and Product Quality

The company owns a Cantonese restaurant serving handmade dim sum. With business growth, a lack of supply…

ANKO Japanese Manju Production Line - Machinery Design For a Japanese Company

This company owns a bakery, selling various buns and bread. Brown sugar is a common ingredient in Asian cooking…

Certification No.

- Taiwan Patent No. M430170

- Taiwan Patent No. I413603

- CN Patent No.201110042873.5

- Downloads

- Best Selling

FAQ

A commercial Automatic Wonton Machine is a valuable investment for food factories, restaurants, and frozen food manufacturers. The HWT-400 automatic Wonton Production Line produces up to 4,000 wonton per hour, significantly reducing labor costs, increasing output, and maintaining consistent quality—far more efficient than manual production. Many ANKO clients have grown from small shops or food carts into major restaurant chains, proving that ANKO equipment delivers long-term production benefits, higher efficiency, and competitive growth in large-scale shumai production.

Yes. Purchasing food machinery includes full service before and after installation. We provide machine testing, product trial runs, and consultation through local offices and distributors worldwide, including the US, Europe, and Asia. After purchase, buyers receive installation, operator training, and after-sales service to ensure stable production. In addition, modular and partially customized options allow manufacturers to adjust machine settings to create different product textures, shapes, and flavors efficiently.

The price of a commercial Automatic Wonton Machine depends on its level of automation and customization requirements. ANKO machines can be integrated with vegetable cutters, dough mixers, robotic arms for pick-and-place, and other front- or end-of-line equipment. For frozen food factories and chain restaurants, ANKO provides a one-stop solution where they can obtain all the machines they need.