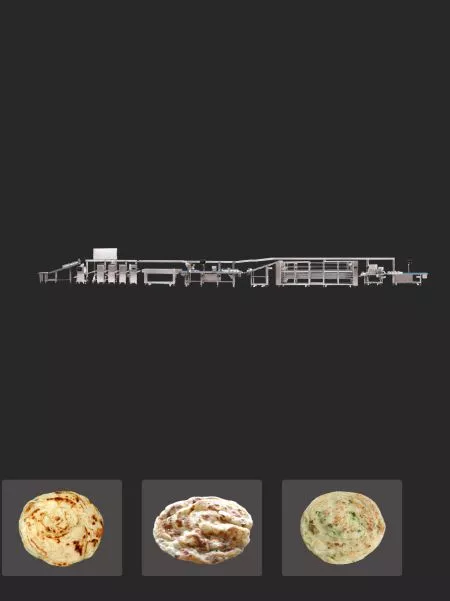

Lachha Paratha and Green Scallion Pie Production Line

Lachha Paratha Machine

Model no : LAP-5000

The crispy layers of parathas or scallion pancakes are craved by people. ANKO's Lachha Paratha & Green Scallion Pie Production Line can produce parathas and scallion pancakes with extremely thin layers because it features a dough stretching device, which can stretch dough into a 0.8 mm thin sheet. By simply putting dough, scallions, and oil, the Lachha Paratha & Green Scallion Pie Production Line can mass-produce Chinese pancakes, scallion pancakes, and parathas automatically. Want to get a quick quote and consultant? Please click the button below and fill out the form.

How It Works

Food's Gallery

- Flaky paratha

- Multiple layered and fluffy in texture

- Scallions evenly rolled into the pancake

- Rolled up dough balls

- Dough balls are perfectly rolled for pressing

- Perfectly pan-fried paratha

Specifications

- Dimensions: 27,480 (L) x 1,420 (W) x 2,400 (H) mm

- Power: 18 kW

- Capacity: 2,100–6,300 pcs/hr

- Product weight: 50–130 g/pc

- Air consumption: 1,200 L/min (@ 6.5 kg/cm^2)

- Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

-

More efficient dough feederIncline conveyor with an automatic feeding control sensor makes the feeding process smoother.

-

Maintain dough texture4 sheeting rollers gradually roll a chunk of dough into a dough sheet to avoid too much pressure to destroy dough texture.

-

Extremely thin layerThe stretching device stretches the dough sheet into 0.8 mm.

-

Automatic oil feeder with temperature controllerMakes the solid fats and liquid oil drip and keep the feeder unblocked.

-

Scallions sprinkled evenlyThe automatic sprinkling device sprinkles chopped scallions evenly on the dough sheet.

-

Conveyor designed for dough restingThe conveyor is 35 meters long to let the dough rest 8 to 10 minutes.

-

Roll up dough strips for more layersAccording to the dough texture and product size, install the proper weight and number of the stainless steel wire mesh for perfectly rolling up the dough strips.

-

Optional machineryAutomatic Filming and Pressing Machine is available to bundle to continue pressing the roll-up dough balls and filming them for packing.

- One button to quickly start the entire production line

- Cable trunking helps keep cables tidy to make the factory safe and hygiene

- With only 3 persons for operation. One person feeds dough and ingredients and two persons collect products.

Case Studies

What Things to Consider When Setting up a New Lachha Paratha Production Line

In order to increase capacity and improve product quality, the idea of shifting manual to automatic production...

ANKO Lachha Paratha Production Line for an Indian Company

The growth of demand for paratha urges the client to seek automatic production line so as to reduce labor cost and increase productivity...

Automatic Layered Paratha Production Line for a Bangladeshi Company

The client decided to run a paratha production line due to the popularity of paratha. He trusted ANKO with Turnkey Planning Consulting Services...

Green Scallion Pie Production Line Design for a Taiwanese Company

The client would like to save labor cost and increase productivity. He found ANKO to seek the best solution for keeping handmade taste....

Danish Pastry Industrial Production Line for an Indian Company

The client supplies Danish pastries, chapatis, Mille-feuilles and cinnamon rolls, and they wished to upgrade their production capacity in order to increase the revenue…

Stuffed Paratha Machine-Machinery Design for Indian Company

The client planned to expand into the U.S. market. He compared ANKO with other food machine suppliers and found ANKO is superior…

- Downloads

- Best Selling

FAQ

Lachha Paratha and Green Scallion Pie Production Line offer significant value for food factories, restaurants, and frozen food manufacturers. The LAP-5000 reduces labor costs, increases production capacity, and ensures consistent product quality—far more efficient than manual processes. Many ANKO customers have grown from small shops or food carts into major restaurant chains, proving that ANKO’s equipment delivers long-term commercial growth and reliability.

Yes. Purchasing food machinery includes full service before and after installation. We provide machine testing, product trial runs, and consultation through local offices and distributors worldwide, including the US, Europe, and Asia. After purchase, buyers receive installation, operator training, and after-sales service to ensure stable production. In addition, modular and partially customized options allow manufacturers to adjust machine settings to create different product textures, shapes, and flavors efficiently.

The price of the LAP-5000 varies depending on production capacity, automation level, food type, and customization requirements. ANKO offers multiple automated food solutions for Lachha Paratha and Green Scallion Pie, along with dough-mixing equipment, recipe consulting, and full factory layout planning to support diverse manufacturing needs in food factories.