Automatic Shumai Machine

Double Line Shumai Machine

Model no : HSM-600

ANKO’s Automatic Shumai machine has the capacity to produce 5,000 to 6,000 pieces of shumai (siomai) per hour. It only requires loading the pre-mixed dough into the hoppers. ANKO can customize the machine according to client’s demand to produce the weight of the shumai from 14g to 80g per piece and adjust the height between the wrappers and fillings. Additionally, the garnishing device can place ingredients such as green peas or diced carrots onto the shumai for an enhanced visual appearance. If you are interested in this machine and a quotation, please click on the button below and complete the form to receive more information.

How It Works

Food's Gallery

- Garnish can be automatically placed on products

- Siomai filled with pure meat filling

- Siomai made with paper-thin wrappers

- Siomai made with thicker wrappers

- The size of the wrappers is adjustable

- HSM-600 can produce shumai (dim sim) at up to a maximum weight of 80g per piece

Optional Accessories

CE kit

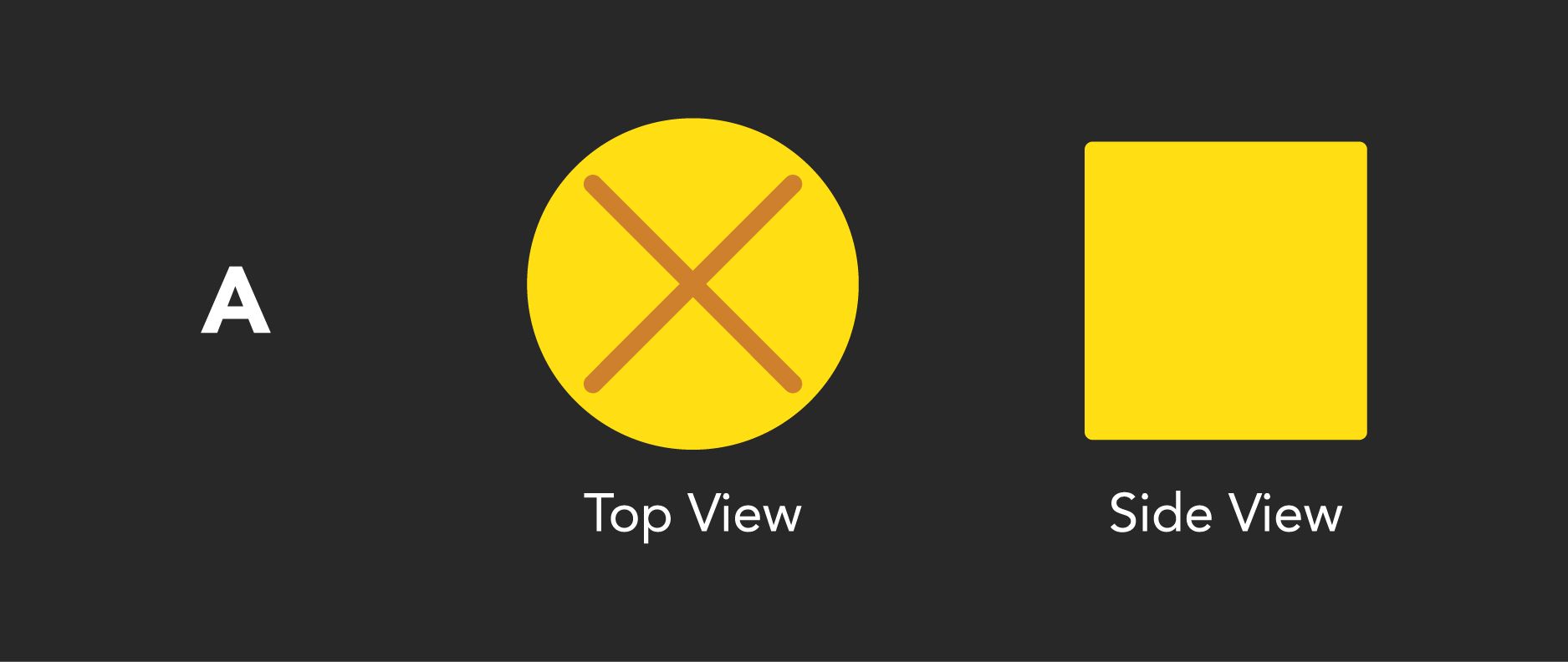

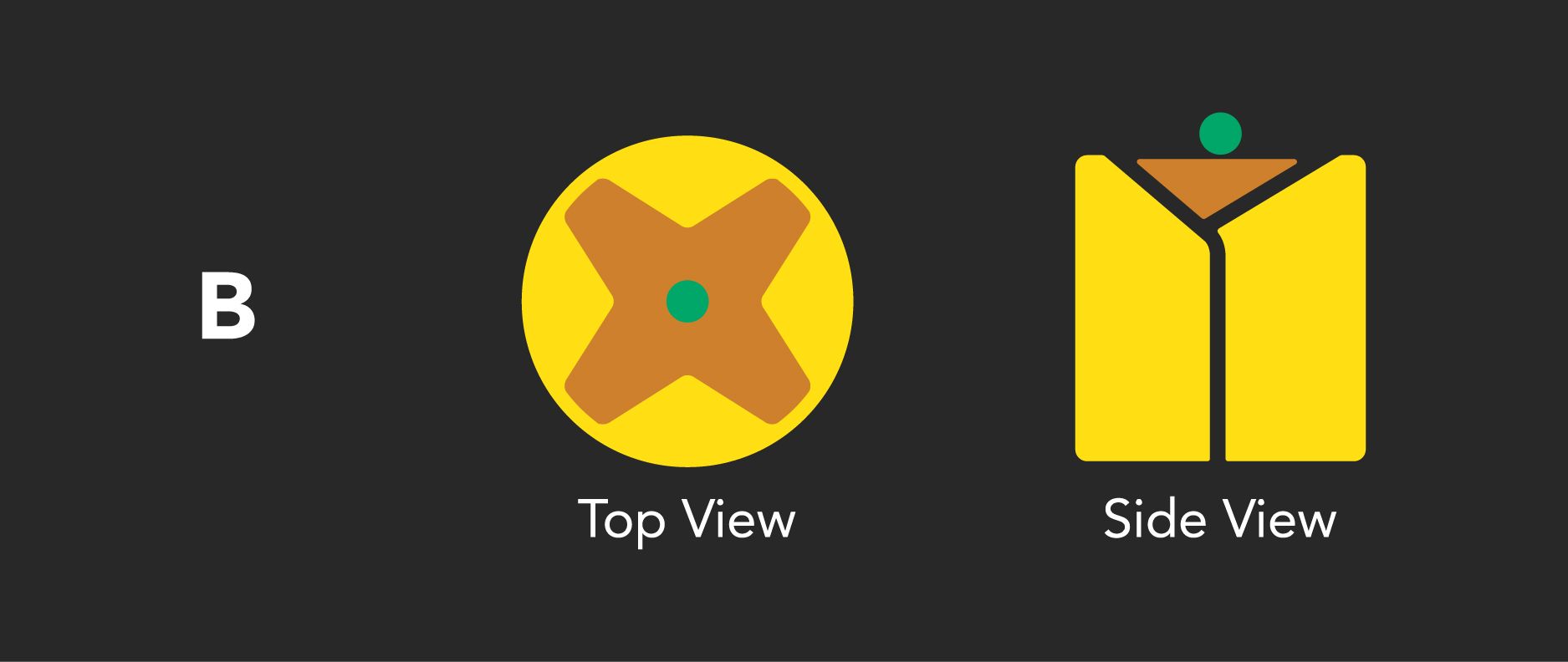

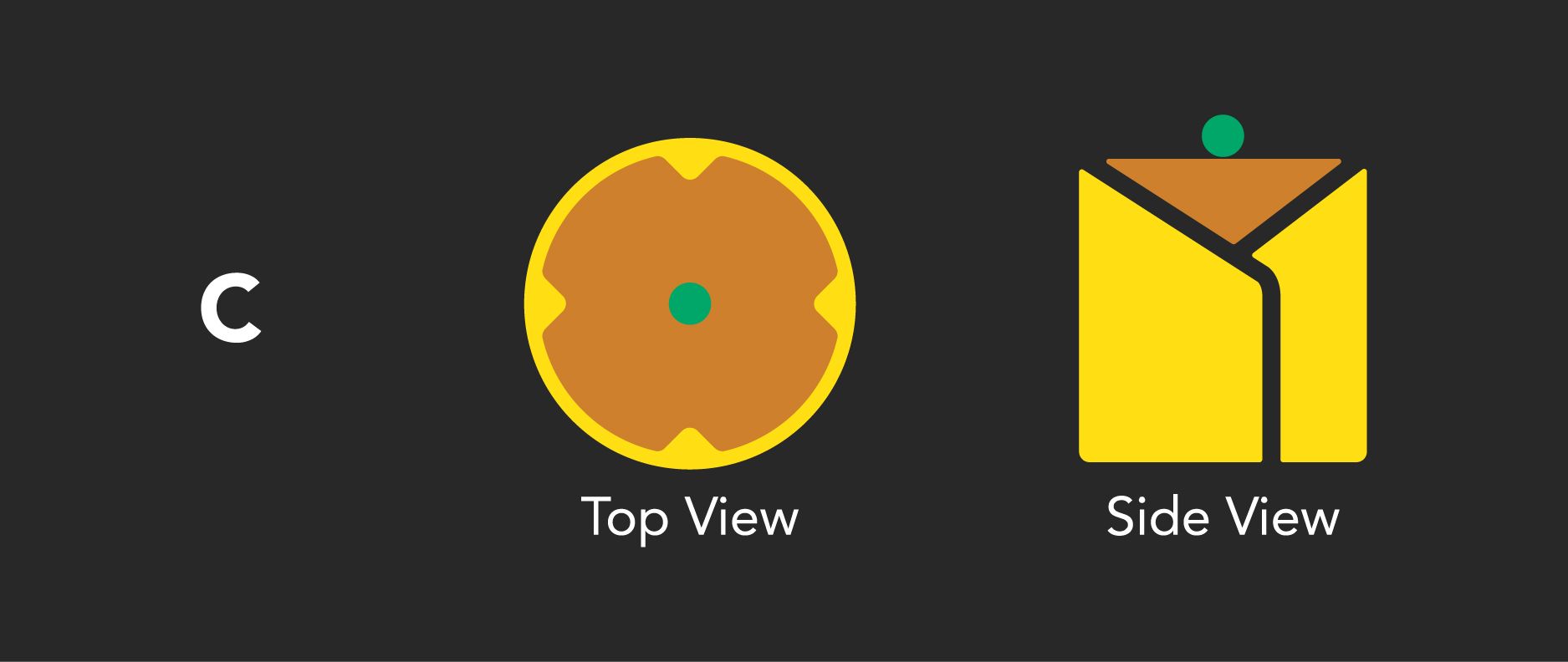

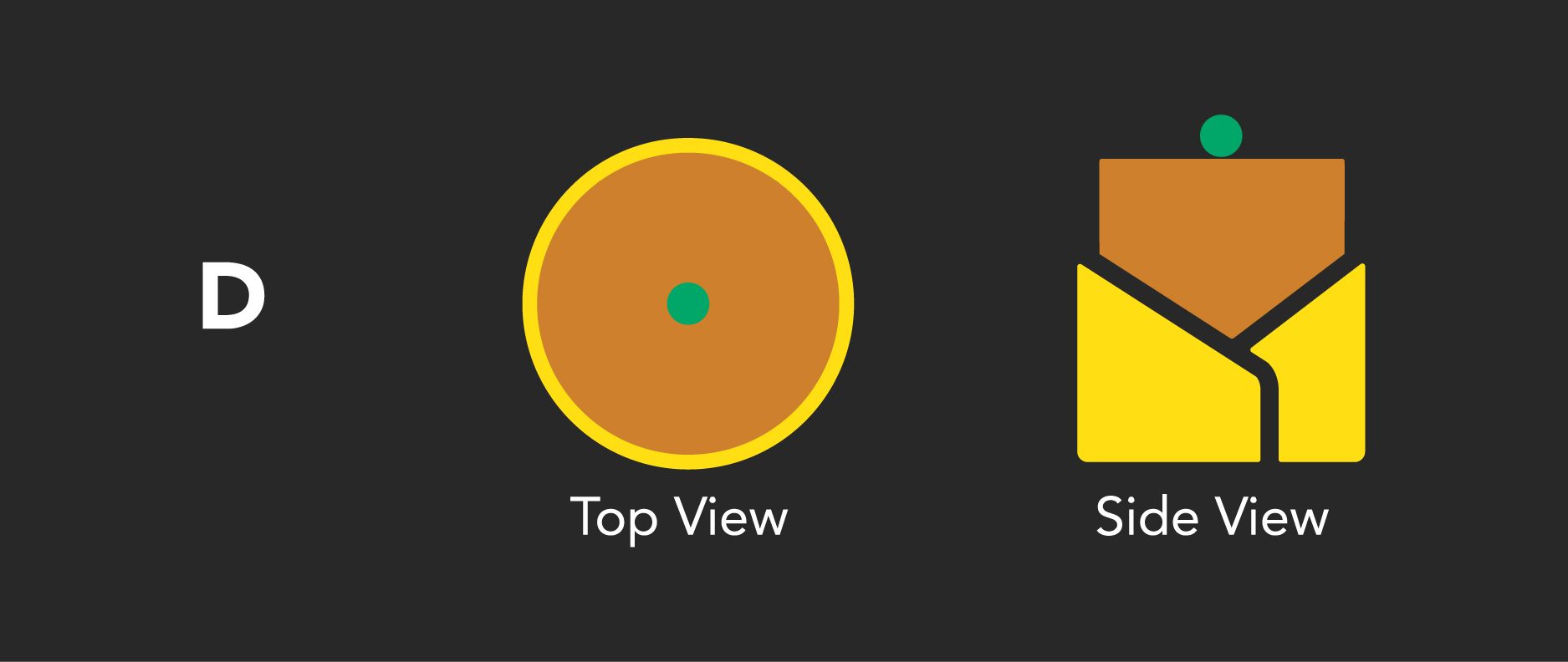

Food Dimension

| Diameter | 25 mm | 30 mm | 32 mm | 35 mm |

| Height | 25-30 mm | 25-30 mm | 25-30 mm | 25-30 mm |

| Weight | 14-16 g | 19-21 g | 20-24 g | 24-30 g |

| Thickness of Pastry | 0.3-0.5 mm | 0.3-0.5 mm | 0.3-0.5 mm | 0.3-0.5 mm |

| Size of Pastry 60x60 mm | B/C | B/D | C/D | C/D |

| Size of Pastry 65x65 mm | A/B | B/C | B/C | B/C |

| Size of Pastry 70x70 mm | A | A/B | A/B | B |

|

|

|

|

Specifications

- Type: Double line

- Dimensions: 1,400 (L) x 1,200 (W) x 1,970 (H) mm

- Power: 3.3 kW

- Capacity: 5,000–6,000 pcs/hr

- Product name: Shumai

- Product dimension: 25–35 (Dia.) x 25–30 (H) mm

- Product weight: 14–30 g/pc

- Dough belt:Width: 60–70 mmThickness: 0.3–0.5 mm

- Optional accessories: CE kit

- Weight (net): 760 kg

Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

-

The Built-in IoT SystemYou can now sign up and log on ANKO’s IoT website to monitor and manage your food production with integrated food production technology. All the manufacturing data and the production yield rate is collected daily and analyzed via Big Data to provide you with cost-effective suggestions for making your production line more effective.

-

Automatic double line shumai machinePutting well-kneaded dough and filling into the hoppers, after switching on machine, it will make dough pastry wrapper by pressing, pulling and cutting, stuffing filling, forming and sending the products to the conveyor automatically.

-

Advanced design and sanitationANKO follows Food and Beverage Safety and Hygiene Policies and Procedures, all the parts in contact with food are made of food standard stainless steel and plastic.

-

Uniform products and high capacityThickness of wrapper and weight of stuffing are adjustable.

-

Product size can be customizedBased on client’s production requirements, ANKO’s machine can produce shumai (dim sim) at up to a maximum weight of 80g per piece.

- The machine is easy for operation, cleaning, assembling, and repairing.

- Its special filling system can apply wide range of filling types such as beef, pork, shrimp, fish paste(surimi) and etc.

- There is a special sensor system installed on our machine which enables the filling system only when there is wrapper on the machine, so there will be no filling loss if you run out of wrapper.

- Special micro adjusting mechanism is installed on the wrapper pressing rollers enable you to adjust wrapper thickness.

Case Studies

Siomay Production Machine Designed to Solve Insufficient Production Capacity

Capacity In order to increase production capacity, the client switched from manual to automatic production and bought a semi-automatic siomay machine....

ANKO Automatic Shumai Machine – Machinery Design for Malaysian Company

With the new online shopping site, the client received more orders than before, so that they planned to purchase machine for....

Automatic shumai machine designed to solve supply shortages of shumai

The client is a co-packer, who has been contracted by many food companies to produce Chinese food and dim sum. ...

Machinery Design for an Indonesian Company

The expansion and increase of business were followed by a problem that their original siomay machine could not meet higher demands, so the client contcted ANKO...

Machinery Design for Mauritian Company

The growing demand and labor costs prompted the client to find an automation solution. Through his friend's introduction, he knew that ANKO is a professional food machine manufacturer...

Chinese Shumai Production Line Design for a Hong Kong Company

With increasing restaurant business, the owner of a dim sum restaurant would like to expand his production capacity with....

Compare models

Certification No.

- TW Patent No.: I413603

- Taiwan Patent No.: M430170

- CN Patent No.: 201110042873.5

- Downloads

- Best Selling

FAQ

A commercial Shumai Machine is a valuable investment for food factories, restaurants, and frozen food manufacturers. The ANKO HSM-600 automatic Shumai Production Line produces up to 6,000 shumai per hour, significantly reducing labor costs, increasing output, and maintaining consistent quality—far more efficient than manual production. Many ANKO clients have grown from small shops or food carts into major restaurant chains, proving that ANKO equipment delivers long-term production benefits, higher efficiency, and competitive growth in large-scale shumai production.

Yes. Purchasing food machinery includes full service before and after installation. We provide machine testing, product trial runs, and consultation through local offices and distributors worldwide, including the US, Europe, and Asia. After purchase, buyers receive installation, operator training, and after-sales service to ensure stable production. In addition, modular and partially customized options allow manufacturers to adjust machine settings to create different product textures, shapes, and flavors efficiently.

The price of a commercial Shumai Machine depends on its level of automation and customization requirements. ANKO offers multiple models of Automated Shumai Machines, which can be integrated with vegetable cutters, dough mixers, robotic arms for pick-and-place, and other front- or end-line equipment. For frozen food factories and chain restaurants, ANKO provides a one-stop solution where they can obtain all the machines they need.