Tortilla Production Line

Automatic Tortilla Production Line

Model no : TT-3600

TT-3600 Tortilla Production Line starts from heat pressing process after putting divided tortilla dough balls by hand. The dough balls would be first evenly flattened by the pressing & heating system, and then baked through tunnel oven, which bakes both sides of the tortilla until delightfully browned in spots. To facilitate packing, the tortilla production line is able to stack required quantity of final products in a pile. The Tortilla Production Line has a total length of 30 meters. It is capable of producing 3,600 tortillas per hour, suitable for large tortilla suppliers or food factories that meet the space requirement and need high productivity. Want to get a quick quote and consultant? Please click the button below and fill out the form.

How It Works

Food's Gallery

- Perfectly baked tortillas

- Produces different types of flatbreads

- Chicken Burritos made with flour tortillas

- Tortilla puffs up during baking

- Tortillas cooking on a conveyor

- Evenly pressed Flatbreads

Specifications

- Dimension: 20,725(L)x1,600(W)x2,280(H)mm

- Power: 52kW

- Capacity: 3,600pcs/hr

- Product dimension: 6-10 inches

- Product weight: 40-60g/pc

- Heating plate: 620(L)x600(W)mm

- Gas consumption:LPG: 12kg/hrNaturalgas: 18 m^3/hr

- Air consumption: 0.8 m^3/min

Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

-

Precise dough locating jigHelps operators locate dough balls in position effortlessly.

-

Distance control with sensorsDistance between dough balls is automatically controlled by sensors and two independent conveyors.

-

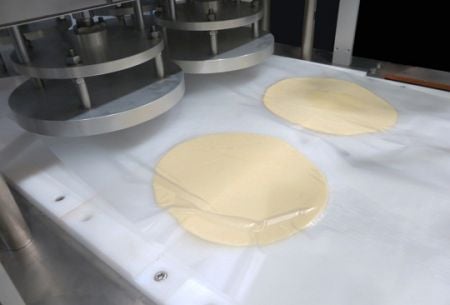

Hydraulic pressing & heating systemPresses dough balls evenly without being affected by the hardness and shape of dough balls.

-

Safety interlockPressing & heating system will stop immediately when the guard is opened.

-

High-productivity pressing & heating systemPresses 4 pieces of 8 to 10-inch products at a time. The average production capacity is 1 piece per second.

-

Three-layer tunnel ovenIndependent control of 8 burners and top/bottom baking temperature. After turning on, the burners are automatically controlled by temperature sensors to ensure constant temperature.

-

Flame failure alarmFlame failure can be detected.

-

Cooling conveyorCooling fans to cool products rapidly for packing.

-

Counter/stackerStacks products in a pile with accurate numbers counted by sensors.

-

With only 2 persons neededOne person feeds dough and the other collects final products.

-

Advanced safety deviceHydraulic pressing & heating system and tunnel oven are designed with safety devices to avoid danger.

Case Studies

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

Stuffed Paratha Machine-Machinery Design for Indian Company

The client planned to expand into the U.S. market. He compared ANKO with other food machine suppliers and found ANKO is superior…

Automatic Layer Paratha Production Line - Machinery Design for an Indian Company

The client contacted ANKO for food processing equipment solutions due to increasing demands. A total solution of Paratha…

Paratha Automatic Filming and Pressing Machine for a United Arab Emirates Company

The client required a machine to produce large paratha products. Thus, ANKO not only increased the size of pressing plates, but also…

Automatic Layered Paratha Production Line for a Bangladeshi Company

The client decided to run a paratha production line due to the popularity of paratha. He trusted ANKO with Turnkey Planning Consulting Services…

- Downloads

- Best Selling

FAQ

Tortilla Production Line offer significant value for food factories, restaurants, and frozen food manufacturers. The TT-3600 reduces labor costs, increases production capacity, and ensures consistent product quality—far more efficient than manual processes. Many ANKO customers have grown from small shops or food carts into major restaurant chains, proving that ANKO’s equipment delivers long-term commercial growth and reliability.

Yes. Purchasing food machinery includes full service before and after installation. We provide machine testing, product trial runs, and consultation through local offices and distributors worldwide, including the US, Europe, and Asia. After purchase, buyers receive installation, operator training, and after-sales service to ensure stable production. In addition, modular and partially customized options allow manufacturers to adjust machine settings to create different product textures, shapes, and flavors efficiently.

The price of the TT-3600 varies depending on production capacity, automation level, food type, and customization requirements. ANKO offers multiple automated food solutions for tortilla production, along with dough-mixing equipment, recipe consulting, and full factory layout planning to support diverse manufacturing needs in food factories.