Kulcha

Kulcha Machine And Production Solution

Model no : SOL-KCA-0-1

There are numerous types of Indian breads; they are delicious staples and can differ from region to region. The breads are made from numerous different recipes and formed into leavened or unleavened dough. There are also many ways to cook these breads; the most commonly sold and consumed are Naan, Chapati, Roti, and Kulcha. Recently, Indian cuisine has become very popular around the world, and there is a particular interest in Indian bread products. Want to get a quick quote and consultant? Please click the button below and fill out the form.

Automated Production for Different Types of Indian Breads

Kulcha is a soft leavened Indian bread; the dough is made with flour, yeast, oil, salt, and sugar. After the dough is leavened, it can be divided into smaller pieces and ca be made into Amritsari chole Kulcha, Paneer Kulcha, Aloo Kulcha and Masala Kulcha.

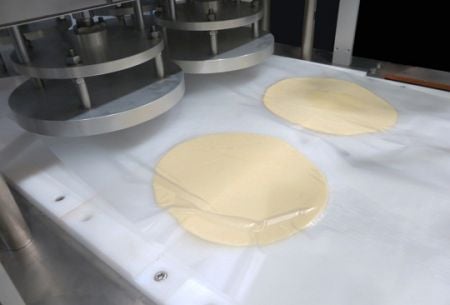

ANKO APB Series - Pressing and Heating Machine is made with aluminized stainless steel, certified food grade materials, and it has the capacity of producing 2,000 pieces per hour. It has a temperature-controlled presser that can be adjusted and timed to make flatbreads with different thickness; necessary for making different types of flatbreads. ANKO has 45 years of experience assisting clients with production planning, configuring commercial mixers and integrating heated pressers and packaging equipment into a production line. ANKO also offers recipe consultation, implementation advice and other services upon request.

Food's Gallery

- Consistent product thickness

- The browning of the Kulcha can be adjusted

- Kulcha made with highly efficient automated machinery

1

Extended Application

- Pressing

Pressing

ANKO’s Kulcha machine is easy to operate; simply enter the parameter settings and then place premade dough balls onto the conveyor belt. The machine then can produce flatbreads that are 1-3mm thick, and it has a two-tier capacity, with one setting that can produce 800 to 1,000 pieces per hour, and a higher setting capable of producing 1,600 to 2,000 pieces per hour to meet your production requirements.

Case Studies

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

A New Lachha Paratha Production Line Set-up for an Indian Company

In order to increase capacity and improve product quality, the idea of shifting manual to automatic production has been lingering in client's mind...

Table Type Automatic Encrusting And Filling Machine-Machinery Design for UK Company

In order to reduce labor cost, the client went to a machinery show and was impressed with ANKO's food machine…

Automatic Layered Paratha Production Line for a Bangladeshi Company

The client decided to run a paratha production line due to the popularity of paratha. He trusted ANKO with Turnkey Planning Consulting Services…

Automatic Samosa Pastry Sheet Machine– Machinery Design for Kuwait Company

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one…

Paratha Automatic Filming and Pressing Machine for a United Arab Emirates Company

The client required a machine to produce large paratha products. Thus, ANKO not only increased the size of pressing plates, but also…

Spring Roll Pastry Machinery Design for a South African Company

The client's businesses, establishing in South Africa, extend from producing frozen food, baking products to central kitchen and catering service…

The Best Selection - Get Started with Us to Discuss Your Needs

Tortilla Production Line

TT-3600 Tortilla Production Line starts from heat pressing process after putting divided tortilla dough balls by hand. The dough balls would be first evenly flattened by the pressing & heating system, and then baked through tunnel oven, which bakes both sides of the tortilla until delightfully browned in spots. To facilitate packing, the tortilla production line is able to stack required quantity of final products in a pile. The Tortilla Production Line has a total length of 30 meters. It is capable of producing 3,600 tortillas per hour, suitable for large tortilla suppliers or food factories that meet the space requirement and need high productivity. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More InfoSpecifications

Capacity: 3,600 pcs/hr

Features

- Voltage can be designated.

- The thickness of kulcha and the amount of filling can be adjusted by parameter setting.

- The shape of kulcha can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

- Downloads

- Best Selling

- Related Food Solutions Type