Roti

Your Roti Production Planning And Roti Recipe Consultant.

Model no : SOL-RTI-S-1

ANKO’s “roti production solution” provides comprehensive consulting service and solves problems of production based on our years of experience, which enables you to automate production with less effort and stress. You can have one-stop shopping for not only roti making machines, such as sieving, wrapper making, and packaging, but also your own proposal that is made ANKO’s sales engineers according to your production needs, factory layouts, existing equipment, human resources, etc. In the solution below, the machines can be adjusted in model and quantity according to real production needs. Want to get a quick quote and consultant? Please click the button below and fill out the form.

About Roti Production Solution

ANKO Roti Production Line guarantees you high efficiency and quality food products. The automatic production line can make rotis efficiently with the least manpower. After placing divided dough balls on the conveyor, the production line can make 3,600 pieces of rotis per hour through the process of pressing, baking, cooling, and stacking for packaging. The special heat and press system can evenly press dough balls to make all rotis look great and have consistent quality.

Food's Gallery

- The thickness of the Roti is adjustable

- Machine pressing time and temperature can be adjusted to meet the client’s product specifications

- Made with highly efficient automated production

- Roti are made to uniformed size and weight

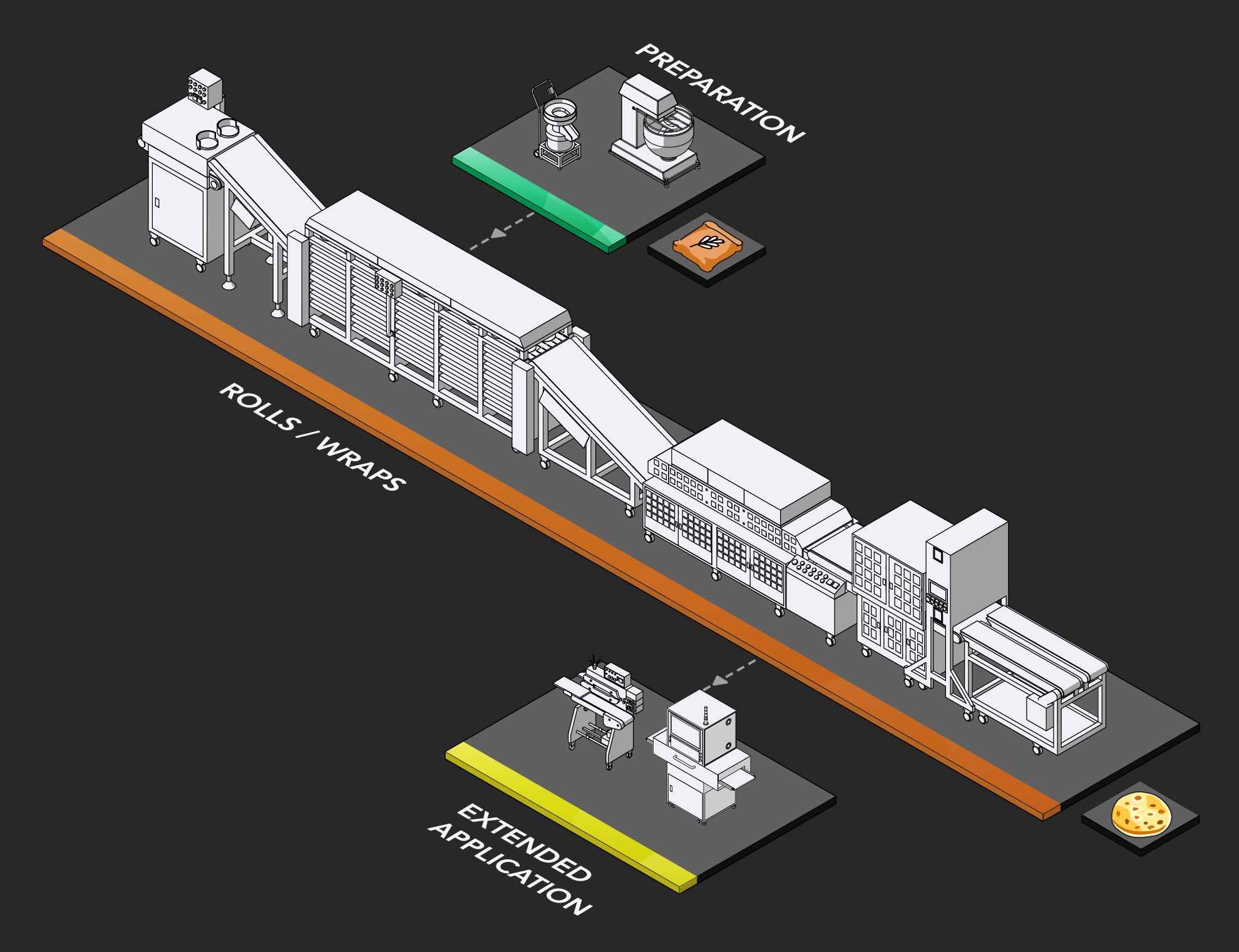

Turnkey and Production Planning

1

Preparation

- Sieving

- Mixing

2

Rolls / Wraps

- Sheeting / Wrapping

3

Extended Application

- Sealing

Sealing

For packaging rotis, ANKO provides specialist packaging machines for you to choose to facilitate the entire process from producing to packaging. If you have any requirements, do not hesitate to let ANKO’s sales engineers know, we will provide the most professional and suitable solution depending on your needs.

- Quality Control

Quality Control

ANKO’s X-Ray Inspection Machine can detect various metals, bones, glass, and other foreign objects during food production; even something as small as 0.4mm. The machine is equipped with luminating and buzzer warnings to ensure real-time contaminant detection, prevent artificial hazards, and increase overall product quality.

Case Studies

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

Automatic Layered Paratha Production Line for a Bangladeshi Company

The client decided to run a paratha production line due to the popularity of paratha. He trusted ANKO with Turnkey Planning Consulting Services…

Automatic Layer Paratha Production Line - Machinery Design for an Indian Company

The client contacted ANKO for food processing equipment solutions due to increasing demands. A total solution of Paratha…

Automatic Samosa Pastry Sheet Machine– Machinery Design for Kuwait Company

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one…

Automatic Samosa Pastry Sheet Machine - Machinery Design for Indian Company

The client runs a bakery group whose divisions are present in many countries of the Middle East and Asia. They form a complete…

Stuffed Paratha Machine-Machinery Design for Indian Company

The client planned to expand into the U.S. market. He compared ANKO with other food machine suppliers and found ANKO is superior…

Table Type Automatic Encrusting And Filling Machine-Machinery Design for UK Company

In order to reduce labor cost, the client went to a machinery show and was impressed with ANKO's food machine…

The Best Selection - Get Started with Us to Discuss Your Needs

Tortilla Production Line

TT-3600 Tortilla Production Line starts from heat pressing process after putting divided tortilla dough balls by hand. The dough balls would be first evenly flattened by the pressing & heating system, and then baked through tunnel oven, which bakes both sides of the tortilla until delightfully browned in spots. To facilitate packing, the tortilla production line is able to stack required quantity of final products in a pile. The Tortilla Production Line has a total length of 30 meters. It is capable of producing 3,600 tortillas per hour, suitable for large tortilla suppliers or food factories that meet the space requirement and need high productivity. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More InfoSpecifications

Capacity:280 kg/hr or 3,600 pc/hr

*Based on 80-gram roti

Features

- Voltage can be designated.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

What services and benefits are covered in the solution?

One-stop roti production solution allowing you to get all services from purchase to installation from one single place

In order to automatically make rotis, you have to buy a series of machines for forming, cooking, and packing. Do you feel that you spend a lot of time and effort contacting different suppliers? ANKO provides roti production solution to meet all your needs. Not only equipment, but also a professional food lab is available to help you ensure the machine and machine-made food satisfy your needs. Moreover, when your machine arrived, our installation and training services can help you save time and effort. All you need will be completed in one procurement.

All your roti production planning and questions will be handled by a professional

With 45 years' experience in manufacturing consulting service, we have the know-how to not only plan the most efficient production flow based on the layout of your factory, but also provide suggestions for machine installation, including electrical wiring and connection between machines according to your production of rotis. In addition, ANKO assists you in thoroughly assessing the effectiveness of a solution. For example, you could spend more time and money on business administration and development.

Maintain roti production efficiency, save time on primary decision

Many owners might have unpleasant experience of contacting customer service for roti machine repair, especially when a problem is handled by different customer service specialists. The long process might affect roti production capacity and lead to unexpected losses caused by shutdown and delivery delays. Hand over your concerns to ANKO! We provide a custom-made one-stop solution for you and assign a specific person to help all things from purchase to repair. Moreover, our comprehensive database records all your machine details to reduce the risks of loss someday.

"Taste of Tradition, Pioneer in Production", ANKO provides the most suitable suggestion on roti recipe

Every customer of ANKO is unique and important. From our 45 years of experience, we have enhanced our roti machines to make it better and collected more than 100 food recipes to offer you more comprehensive services. ANKO will always be with our customers to resolve difficulties, challenges, or questions about market experience, roti recipe adjustment, and production line planning to achieve greater success in preserving the taste of tradition.

- Best Selling

- Related Food Solutions Type