Multipurpose Filling and Forming Machine

Automatic Dumpling Machine

Model no : HLT-700U

ANKO’s most powerful Dumpling Machine, the “HLT-700U Multipurpose Filling and Forming Machine” is integrated with a new filling system! It can process large pieces of food ingredients, less oil, and high roughage fillings, as well as cooked meats that are less viscous. Not only it can handle a wide range of ingredients, but it can also produce dumplings that are plump and look handmade. This machine is compact in size (less than 1.5 square meters) and when forming dumplings at 25g per piece, it has the capacity of producing 12,000 pieces per hour. It is suitable for independently owned restaurants and large food factories. The IoT (Internet of Things) have been installed to ensure that the production can be overseen by managers in real time on a mobile device, and the data can be collected and processed through Big Data Analytics to support decision making. We have also installed a maintenance reminder program to ensure consistent productivity. Please click on the link below to fill out the form and our sales professionals will get back to you with customized solutions for your food production specifications.

How It Works

Food's Gallery

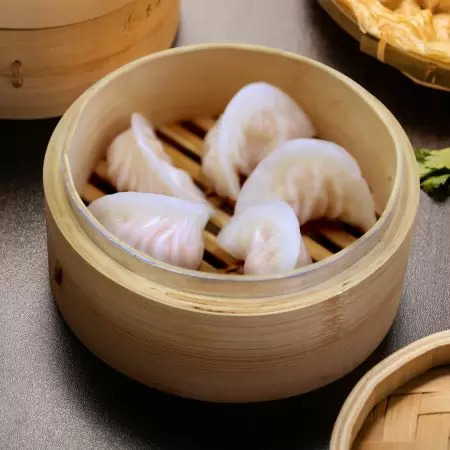

- Handmade Pleats Mold

- Handmade Pleats Mold

- Wave Edge Mold

- Wave Edge Mold

- Wavelike Edge Mold

- Thin Edge Mold

- Mold Customization

- Plant-based Filling

- Vegan Dumpling

- Sakura Edge Mold

- Sakura Edge Mold

Optional Accessories

Filling rotor, Standard mold, Double-sided molds, Noodle mold, CE kit

Shape

| Shape | Semi Circle | Triangle | Square | Circle | Pleat | Rectangle |

| Demo |  |  |  |  |  |  |

| Length | 15-200 mm | 60-120 mm | 35-80 mm | Dia.30-65 mm | 45-55 mm | 35-80 mm |

| Width | 10-100 mm | 50-85 mm | 35-80 mm | Dia.30-65 mm | 30-35 mm | 30-45 mm |

Pattern

| Without Pattern | Semicircle Pattern | Shell Pattern | Nail Pattern | Ladder Pattern |

|  |  |  |  |

In addition, we also provide Mold Customization, please click, click Learn More>

Specifications

- Dimensions: 1,515 (L) x 615 (W) x 1,640 (H) mm

- Power: 6.5 kW

- Capacity: 2,000–12,000 pcs/hr

- Product name: Dumpling, Potsticker, Fried leek dumpling, Curry puff, Noodle, Roll, Pie

- Product weight: 13–100 g/pc

- Optional accessories: Filling rotor, Standard mold, Artisan mold, Noodle mold, CE kit

- Weight (net): 540 kg

- Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

-

The Built-in IoT SystemYou can now sign up and log on ANKO’s IoT website to monitor and manage your food production with integrated food production technology. All the manufacturing data and the production yield rate is collected daily and analyzed via Big Data to provide you with cost-effective suggestions for making your production line more effective.

-

Operates using New Eco-Friendly RefrigerantsEco-Friendly Refrigerants have the same cooling effect but with only 1/10 of the GWP measure and comply with EU standards.

-

Easy-to-use control panelUser-friendly interface allows you to operate the machine easily and up to 99 recipes can be saved.

-

Filling hopper with quick mounting designMakes the filling hopper easier and more convenient to install or uninstall for cleaning.

-

Filling hopper with stepper stripPrevents filling from spinning in the hopper and keeps filling feeding stably.

-

48-liter filling hopperHelps decrease refilling times and increase the overall efficiency of human resources.

-

Optimized dough feeding screwsMake dough pass screws directly and be extruded smoother to prevent spinning problem.

-

Enhance water resistanceUpgraded rubber seal can exactly fit the machine cabinet frames.

-

Tasty AppearanceA whole new design of shaping mechanism to enhance the food’s handmade look.

-

Better TasteFilling feeding system enhancement to reduce pressure and keep food texture.

Case Studies

HLT-700U x Wave Edge Mold: ANKO provided successful Pierogi Production Solutions for a Polish client

Pierogi is one of the national staples of Poland. This client initially relied heavily on producing Pierogi manually, then later switched to…

Dumpling Machine Helps to Increase Capacity and Standardize Products

Consumers really liked the handmade dumplings, but 'sold out" was the most important issue with which the company had to deal.…

Dumpling Equipment Designed to Enhance a Food's Handmade Look

"Do you have other more natural patterns?", "Do you have pinching patterns?" To response these demands, we started a series of development processes……

Automatic Har Gow Machinery Design for a Dutch Company

In order to increase productivity, the client was looking for professional food machine supplier. They heard that ANKO manufactured high quality Har Gow machine…

Additive-Free Dumpling Machinery Design for a Singaporean Company

A client and her partners started a business in Singapore. These entrepreneurs later decided to invest in the Chinese Dim Sum…

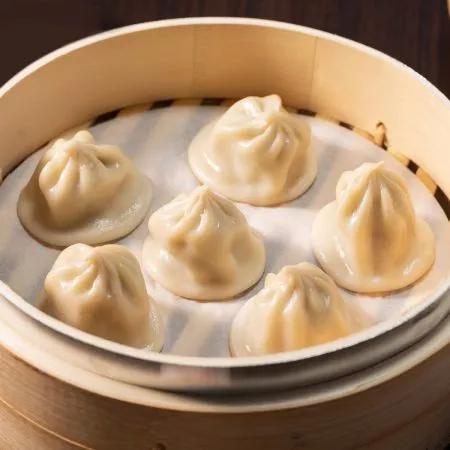

Xiao Long Bao Making Machine - Machinery Design for Dutch Company

The client started his business by opening a restaurant in Netherlands, serving dim sum dishes. He studied the Dutch flavor and healthy…

Sambousek Automatic Production Equipment Designed with a Customized Half-moon Rotary Mold

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products online…

Compare models

| Model no | Multipurpose Filling and Forming Machine HLT-700U | Multipurpose Filling and Forming Machine HLT-700XL | Double-Line Multipurpose Filling and Forming Machine HLT-700DL |

|---|---|---|---|

| Description | Tasty Appearance as handmade look | A wide range of standard rotary molds are available | Highest production capacity |

| Capacity | 2,000 - 12,000 pcs/hr | 2,000 - 10,000 pcs/hr | 4,000 - 20,000 pcs/hr |

| Weight | 13 - 100 g/pc | 13 - 100 g/pc | 13 - 100 g/pc |

| More Info | More Info | More Info |

- Downloads

- Best Selling

FAQ

Commercial dumpling machines are worth the investment for food manufacturing companies, restaurants, and frozen food manufacturers. The HLT-700U helps reduce labor costs, increase production capacity, and maintain consistent product quality, making it far more efficient than manual production. Many businesses have scaled from small shops or food carts to large chain restaurants with the support of ANKO’s machines, proving their long-term value in business growth.

Yes. Purchasing food machinery includes full service before and after installation. We provide machine testing, product trial runs, and consultation through local offices and distributors worldwide, including the US, Europe, and Asia. After purchase, buyers receive installation, operator training, and after-sales service to ensure stable production. In addition, modular and partially customized options allow manufacturers to adjust machine settings to create different product textures, shapes, and flavors efficiently.

Commercial dumpling machine prices vary depending on capacity, automation level, and customization options. The HLT-700U can be integrated with upstream vegetable cutting and dough mixing equipment, as well as downstream steaming or freezing systems to meet full production line needs. While mid-to-large commercial dumpling machines require higher investment, they significantly reduce labor costs and ensure consistent output. With just two steps to change attachments, the HLT-700U can produce multiple food shapes, such as dumplings and ravioli, making it ideal for manufacturers seeking efficiency and product variety.