Gyoza

Gyoza Machine and Production Solutions

Model no : SOL-SGZ-0-1

Gyoza is a widely popular dish because they are easy to cook, convenient to store in the freezer, and ready to eat in minutes. Research indicates that the frozen Gyoza market will generate an estimated $3.66 billion by 2024; hence many manufacturers and food brands are researching and testing different Gyoza wrapper thicknesses, filling ingredients, and pleat designs. Companies are also trying to develop their own “secret” recipes to win over consumers. ANKO is the leader in automatic Dumpling forming machines in Taiwan, and we are dedicated to providing you with machines that can produce products with different specifications. Want to get a quick quote and consultant? Please click the button below and fill out the form.

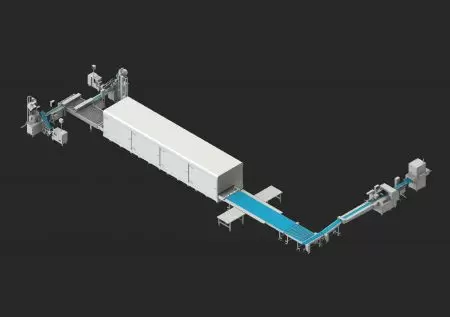

Planning an Efficient Gyoza Production Line

ANKO HLT-700U Automatic Gyoza Forming Machines has a unique dough hopper that can process hot-water dough or partial hot-water dough without over-stretching, thus producing Gyoza that can be pan-fried to achieve a delicate, soft, and crispy wrapper texture. This filling system is upgraded and capable of handling a variety of ingredients and even pieces that are 10mm in diameter such as whole shrimp, and various vegetables. You can easily produce Pork Gyoza, Beef Gyoza, Kimchi Shrimp Gyoza, Shrimp Gyoza, Cabbage Gyoza and different types of Vegetarian Gyoza.

Using the “Artisan Forming Molds”, ANKO’s machine has a capacity of producing 7,000 pieces of plumply formed Gyoza per hour. There are many molds to choose from; such as the “Wave Edge Mold” for making dumplings with crimped edges that look like they were pinched and twisted by hand; and the “Handmade Pleats Mold” that mimics hand pinched edges.

This Gyoza machine is compact, takes up less than 1 square meter of surface space and has the capacity of producing 2,000 to 12,000 pieces per hour. To start the production process, simply load the hoppers with dough and filling ingredients, and push start on the touch screen, and this user-friendly control panel has 99 memory settings that can adjust the machine to meet your production scale and requirements. ANKO HLT-700U Automatic Gyoza Forming Machines are highly efficient, and utilizing environmentally friendly refrigerants that meet EU regulations. This machine is suitable for individually owned restaurants, cruise ships, schools, food factories, hotel groups and many other applications.

HLT-700U has a built-in Internet of Things (IoT) system which is connected to the Big Data Analytics. It collects data from each production and be utilized with extended applications to manage production balances, warehousing and scheduling. This technology offers you full control over production by “monitoring the machine operational status, maintenance machine lifespan, and digital production management”. An alarm will inform you the exact part that needs inspection to reduce any possible risks.

Food's Gallery

- Great quality Gyoza made with highly efficient automated machinery

- Mold Customization

- Handmade Pleats Mold

- Handmade Pleats Mold

- Wave Edge Mold

- Wavelike Edge Mold

- Thin Edge Mold

- Mold Customization

- Mold Customization

- Plant-based Filling

- Vegan Gyoza

- Vegan Gyoza

1

Filling / Forming

- Forming

Case Studies

Multipurpose Filling & Forming Machine - Machinery Design for Taiwanese Company

Potsticker is popular in Great China area, so the supply was often unable to meet the demand. Thus, the client decided to manufacture with machine…

Dumpling Equipment Designed to Enhance a Food's Handmade Look

Sometimes machine-made dumplings cannot meet client's required shape. Thus, ANKO designed handmade pleats…

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

The Noodle Extruder can be used to produce Noodle, Spaghetti and Noodles with Multi Structured, such as heart-shaped, fish-shaped, dumbbell-shaped, and…

Additive-Free Dumpling Machinery Design for a Singaporean Company

A client and her partners started a business in Singapore. These entrepreneurs later decided to invest in the Chinese Dim Sum…

Green Scallion Pie Production Line Design for a Taiwanese Company

The client would like to save labor cost and increase productivity. He found ANKO to seek the best solution for keeping handmade taste....

Shanghai Wonton Machine Design to Solve Labor Shortage

ANKO customized two rotary molds to help the client mass-produce shanghai wontons that were complicated to fold by hand…

Automatic Wonton Machinery Design for a Canadian Company

With the growing number of branch stores, the client has to prepare more and more pieces of wonton every day. Therefore, they start to…

The Best Selection - Get Started with Us to Discuss Your Needs

Multipurpose Filling and Forming Machine

ANKO’s most powerful Dumpling Machine, the “HLT-700U Multipurpose Filling and Forming Machine” is integrated with a new filling system! It can process large pieces of food ingredients, less oil, and high roughage fillings, as well as cooked meats that are less viscous. Not only it can handle a wide range of ingredients, but it can also produce dumplings that are plump and look handmade. This machine is compact in size (less than 1.5 square meters) and when forming dumplings at 25g per piece, it has the capacity of producing 12,000 pieces per hour. It is suitable for independently owned restaurants and large food factories. The IoT (Internet of Things) have been installed to ensure that the production can be overseen by managers in real time on a mobile device, and the data can be collected and processed through Big Data Analytics to support decision making. We have also installed a maintenance reminder program to ensure consistent productivity. Please click on the link below to fill out the form and our sales professionals will get back to you with customized solutions for your food production specifications.

More Info Compare searies machineCompare with Similar Models

| Model no | Multipurpose Filling and Forming Machine HLT-700U | Multipurpose Filling and Forming Machine HLT-700XL | Double-Line Multipurpose Filling and Forming Machine HLT-700DL |

|---|---|---|---|

| Description | Tasty Appearance as handmade look | A wide range of standard rotary molds are available | Highest production capacity |

| Capacity | 2,000 - 12,000 pcs/hr | 2,000 - 10,000 pcs/hr | 4,000 - 20,000 pcs/hr |

| Weight | 13 - 100 g/pc | 13 - 100 g/pc | 13 - 100 g/pc |

| More Info | More Info | More Info |

Specifications

Capacity: 12,000 pcs/hr or 250 kg/hr

Features

- The built-in IoT function integrates the automated production line, and you can access this through remote monitoring via ANKO’s IoT dashboard.

- Voltage can be designated.

- The thickness of stick gyoza wrapper and the amount of filling can be adjusted by parameter setting.

- The shape of stick gyoza can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

Would you like to find machines or integrated production line?

- Downloads

- Best Selling

- Related Food Solutions Type