mandu

Your mandu Production Planning And mandu Recipe Consultant.

Model no : SOL-MDU-0-1

ANKO has more than 45 years of successful sales expansion experience in the Food Equipment Industry; we supply professional Mandu Machinery and Equipment, and we also provide customized production solutions to help your business transition into fully automated manufacturing to increase productivity and efficiency; furthermore, ANKO can work with you on tailor-designed recipes. Want to get a quick quote and consultant? Please click the button below and fill out the form.

Mandu Production Solutions to Meet Your Specifications

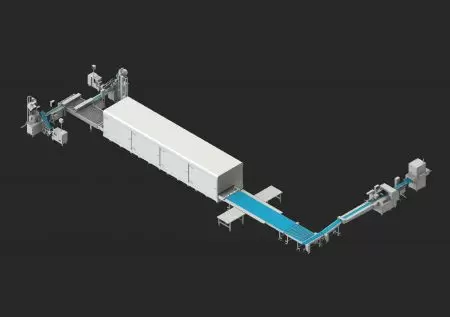

ANKO HLT-700U Multipurpose Filling and Forming machine has the maximum production capacity of 12,000pc of Mandu or other types of dumplings per hour. We also offer customized services and equipment such as dough mixers, filling and forming devices and package machines to implement your production line, so we can help meet most of your manufacturing specifications in one stop, and avoid unnecessary delays.

HLT-700U Multipurpose Filling and Forming Machine has a built-in Internet of Things (IoT) system which is connected to the Big Data Analytics. It collects data from each production and be utilized with extended applications to manage production balances, warehousing and scheduling. This technology offers you full control over production by “monitoring the machine operational status, maintenance machine lifespan, and digital production management”. An alarm will inform you the exact part that needs inspection to reduce any possible risks.

Food's Gallery

- Handmade Pleats Mold

- Handmade Pleats Mold

- Wave Edge Mold

- Wave Edge Mold

- Wavelike Edge Mold

- Wavelike Edge Mold

- Thin Edge Mold

- Mold Customization

- Plant-based Filling

- Tasty Appearance

- Vegan Dumpling

- Vegan Dumpling

1

Filling / Forming

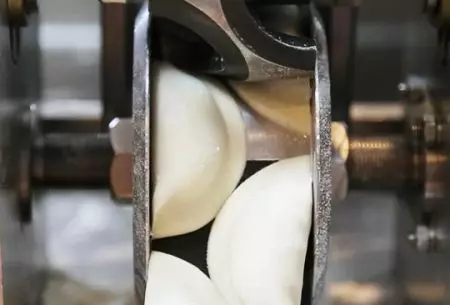

- Forming

Forming

ANKO’s Mandu Machinery and Equipment is easy to operate, and can guarantee the quality, uniformity of products and the consistency of filling in the dumplings when being mass-produced. The production can start after loading the hoppers with dough and desired fillings separately, followed by simple parameter settings.

Case Studies

Shanghai Wonton Machine Design to Solve Labor Shortage

ANKO customized two rotary molds to help the client mass-produce shanghai wontons that were complicated to fold by hand…

Automatic Vegetarian Dumpling Machine for a Taiwanese Company

Vegetarian foods are the client's primary products. The manual production no longer meets the growing demands, in order to boost productivity…

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

The Noodle Extruder can be used to produce Spaghetti, Noodle and Noodles with Multi Structured, such as heart-shaped, fish-shaped, dumbbell-shaped, and…

Ready-to-eat Tapioca Pearl Recipe Development for a Taiwanese Company

This Taiwanese client had no experience in tapioca pearl production and was referred by the OEM company to consult with ANKO…

Cheese Spring Roll Automatic Equipment Designed with a Customized Filling Mold

This cooperation is not the first time. The client had bought our machine before and was satisfied with quality and productivity…

Automatic Encrusting and Forming Machine - Machinery Design for Taiwanese Company

The client used to make their food products by hand. With more and more restaurants opened, the continuing growth in demand…

Multipurpose Filling and Forming Machine-Machinery Design for Indonesian Company

The client has two fishing vessels and two fish processing plants to process the six-ton daily catch. One plant is dedicated to…

The Best Selection - Get Started with Us to Discuss Your Needs

Multipurpose Filling and Forming Machine

ANKO’s most powerful Dumpling Machine, the “HLT-700U Multipurpose Filling and Forming Machine” is integrated with a new filling system! It can process large pieces of food ingredients, less oil, and high roughage fillings, as well as cooked meats that are less viscous. Not only it can handle a wide range of ingredients, but it can also produce dumplings that are plump and look handmade. This machine is compact in size (less than 1.5 square meters) and when forming dumplings at 25g per piece, it has the capacity of producing 12,000 pieces per hour. It is suitable for independently owned restaurants and large food factories. The IoT (Internet of Things) have been installed to ensure that the production can be overseen by managers in real time on a mobile device, and the data can be collected and processed through Big Data Analytics to support decision making. We have also installed a maintenance reminder program to ensure consistent productivity. Please click on the link below to fill out the form and our sales professionals will get back to you with customized solutions for your food production specifications.

More Info Compare searies machineCompare with Similar Models

| Model no | Multipurpose Filling and Forming Machine HLT-700U | Multipurpose Filling and Forming Machine HLT-700XL | Double-Line Multipurpose Filling and Forming Machine HLT-700DL |

|---|---|---|---|

| Description | Tasty Appearance as handmade look | A wide range of standard rotary molds are available | Highest production capacity |

| Capacity | 2,000 - 12,000 pcs/hr | 2,000 - 10,000 pcs/hr | 4,000 - 20,000 pcs/hr |

| Weight | 13 - 100 g/pc | 13 - 100 g/pc | 13 - 100 g/pc |

| More Info | More Info | More Info |

Specifications

Capacity: 12,000 pcs/hr or 250 kg/hr

Features

- The built-in IoT function integrates the automated production line, and you can access this through remote monitoring via ANKO’s IoT dashboard.

- Voltage can be designated.

- The thickness of mandu wrapper and the amount of filling can be adjusted by parameter setting.

- The shape of mandu can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

Would you like to find machines or integrated production line?

- Downloads

- Best Selling

- Related Food Solutions Type