Automatic Table-Type Encrusting and Forming Machine

Stuffed Bun, Mochi Machine

Model no : SD-97SS

The SD-97SS Automatic Table-Type Encrusting and Forming Machine can make various ethnic foods such as meat bun, maamoul, meat pie, pan fried filled bun, mochi, and crystal dumpling. In addition, products with pattern or non-pattern; with bean paste, meat, sesame paste or no filling can be produced. It is the most compact and affordable model of the SD-97 Series, suitable for restaurants, central kitchens, and small food factories. Want to get a quick quote and consultant? Please click the button below and fill out the form.

How It Works

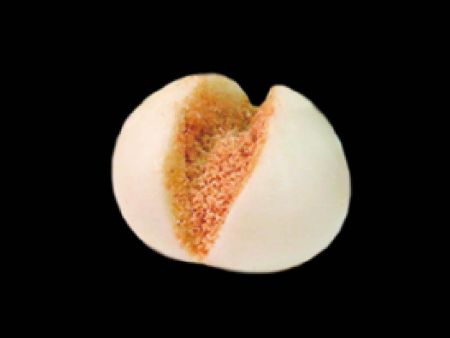

Food's Gallery

- Cylindrically shaped cham cham

- Crystal dumpling filled with minced meat

- Teardrop-shaped nastar

- Special patterns

- Spherical-shaped

- Spherical-shaped mochi

- Fried sesame balls filled with bean paste

- Tang Yuan filled with bean paste

- Tang Yuan filled with bean paste

- Nastar filled with jams

- Meat ball

- Gulab Jamun

Optional Accessories

Shutter piece, Raising base, CE kitSpecifications

- Dimensions: 1,120 (L) x 550 (W) x 1,300 (H) mm

- Power: 0.7 kW

- Capacity: 600–3,600 pcs/hr

- Product weight: 10–60 g/pc

- Weight (net): 100 kg

- Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

- Easy to operate with flexible functions.

- Both conveyor and rotary plate are provided for collecting final products.

- Different shutter units are available for making plain or pleated products and easy to change.

- It can process various types of dough whether the flour dough or glutinous rice dough.

- Suitable for types of fillings, such as bean pastes, powder, mince meats, crushed nuts and etc.

- Each production stage can be controlled individually and conveyor speed can be adjusted as well.

Case Studies

Table Type Automatic Encrusting And Filling Machine-Machinery Design for UK Company

In order to reduce labor cost, the client went to a machinery show and was impressed with ANKO's food machine…

Kubba Automatic Production Equipment Designed to Solve the Forming Problem Caused by Sticky Crust

The production demand has increased since the client sold products in multi-channel. Thus, he was looking for an expert of food machine…

Glutinous Rice Ball Machinery Designed to Solve Problem of Extruding Dry Filling

The client visited ANKO's booth at a Hong Kong exhibition for a solution to produce glutinous rice balls effectively…

Kibe Automatic Production Equipment Designed for a French Company

Kibe (Kibbeh) is one of the basic cuisines in the Middle East, so the high demand has made client's business booming. However, his employees couldn't meet…

Pineapple Cake Automatic Production Line Set up for New Product Launch

The client found that Taiwanese pineapple cake is very popular and delicious, so he decided to produce pineapple cakes and sell…

Automatic Encrusting and Forming Machine - Machinery Design for Hong Kong Company

With current frozen equipment and packaging machinery, they would like to increase efficiency and develop other…

Croquetas (Croquette) Automatic Production Line Design for an Indonesia Company

An ANKO client having had a successful food business in Colombia selling croquetas (croquette) to casinos and other retailers…

Compare models

| Model no | Automatic Table-Type Encrusting and Forming Machine SD-97SS | Automatic Encrusting and Forming Machine SD-97W | Automatic Encrusting and Forming Machine SD-97L |

|---|---|---|---|

| Description | Most compact machine | Two color wrapper is available | Max. product weight up to 200 grams |

| Capacity | 600 - 3,600 pcs/hr | 1,000 - 4,000 pcs/hr | 2,400 - 4,800 pcs/hr |

| Weight | 10 - 60 g/pc | 10 - 70 g/pc | 40 - 200 g/pc |

| More Info | More Info | More Info |

Certification No.

- Taiwan Patent No: 134474, 147243, 068346, 140264

- USA Patent No: US 6, 183, 171 B1 US 6, 251, 462 B1 US 6, 234, 779 B1, US 6, 477,944 B1

- Japan Patent No: 3062865, 3068098

- Netherlands Patent No: Nr. 1017025

- France Patent No: 0102141

- China Patent No: ZL 98 2 25503.9, ZL 98 3 32568.5, ZL 97 2 35267.8, ZL 02 2 15572.4, ZL 02 2 17454.0, ZL 02 2 17453.2

- Downloads

- Best Selling

FAQ

Automatic Table-Type Encrusting and Forming Machine offer significant value for food factories, restaurants, and frozen food manufacturers. The SD-97SS reduces labor costs, increases production capacity, and ensures consistent product quality—far more efficient than manual processes. Many ANKO customers have grown from small shops or food carts into major restaurant chains, proving that ANKO’s equipment delivers long-term commercial growth and reliability.

Yes. Purchasing food machinery includes full service before and after installation. We provide machine testing, product trial runs, and consultation through local offices and distributors worldwide, including the US, Europe, and Asia. After purchase, buyers receive installation, operator training, and after-sales service to ensure stable production. In addition, modular and partially customized options allow manufacturers to adjust machine settings to create different product textures, shapes, and flavors efficiently.

The SD Series includes multiple models, and pricing varies based on production capacity, automation level, product type, and customization needs. Many food factories and restaurant chains choose to invest in commercial units because the SD Series supports a wide range of products—from filled items to dual-color dough and patterned or non-patterned shapes. This flexibility enables seasonal product launches, category expansion, reduced labor dependency, and greater production scalability.