Sesame Ball

Your Sesame Ball Production Planning And Sesame Ball Recipe Consultant.

Model no : SOL-SBL-0-1

Have you been thinking about manufacturing automation? With ANKO’s Sesame Ball production solution, you can receive comprehensive sesame ball production planning and one-stop purchase service. ANKO’s sales engineers can provide consulting services on machine selection, production line planning, workflow, staff deployment, and recipe, according to your needs, factory, and conditions and hand you a tailored production solution. In the solution below, the machines can be adjusted in model and quantity according to real production needs. Want to get a quick quote and consultant? Please click the button below and fill out the form.

About Sesame Ball Production Solution

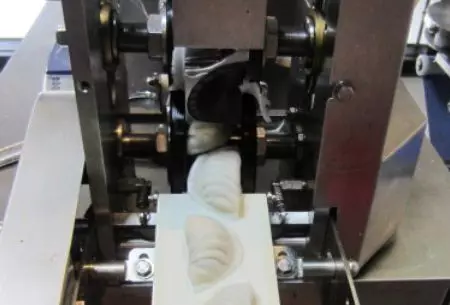

ANKO SD-97 Series Automatic Encrusting and Forming Machines are suitable for producing sesame balls with various types of fillings, including lotus, bean pastes, and sweetened shredded coconut for the sweet sesame balls, or chopped meats, vermicelli and mushrooms in the Vietnamese “bánh rán”. The SD-97SS Table Type Automatic Encrusting and Forming Machine is compact in size and adequate for restaurants or a smaller production. The SD-97W model is slightly larger, it has the capacity of producing up to 4,200pc/hr, and it's engineered with 5 programmable memories and can work with both dry and wet fillings. And the SD-97L Model is specially designed to produce product with wider size range from 40g up to 200g/pc, it also has the maximum capacity of 4,800pc/hr.

“SD-97W Automatic Encrusting And Forming Machine” has a built-in Internet of Things (IoT) system which is connected to the Big Data Analytics. It collects data from each production and be utilized with extended applications to manage production balances, warehousing and scheduling. This technology offers you full control over production by “monitoring the machine operational status, maintenance machine lifespan, and digital production management”. An alarm will inform you the exact part that needs inspection to reduce any possible risks.

Food's Gallery

- Sesame Balls made with highly efficient automated machinery

- Sesame Balls are deep-fried into an airy and hollow dessert

- The dough and filling ratio is adjustable

- Fully-filled Sesame Balls (Not Hollow)

- Sesame Balls coated with sesame using an automatic battering machine

1

Filling / Forming

- Forming

Forming

A good filling and forming machine is the key to high-quality products. ANKO's sesame ball forming machine can quickly mass-produce sesame ball products that are uniform in weight and quality and have delightful pleats. The machine is easy to use. Put prepared dough and filling into hoppers, set parameters, and start producing sesame ball.

Case Studies

Table Type Automatic Encrusting And Filling Machine-Machinery Design for UK Company

In order to reduce labor cost, the client went to a machinery show and was impressed with ANKO's food machine…

Automatic Encrusting and Forming Machine - Machinery Design for Hong Kong Company

With current frozen equipment and packaging machinery, they would like to increase efficiency and develop other…

Automatic Har Gao Making Machine for a Hong Kong Company

With the growth of demands, the supply of har gao, made by hand, was unable to meet a large number of orders. Thus, client chose ANKO…

Semi-Automatic Vegetarian Spring Roll Production Line Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

Automatic shumai machine designed to solve supply shortages of shumai

The client is a co-packer, who has been contracted by many food companies to produce Chinese food and dim sum...

Automatic Wonton Production Line Design for a British Company

The client combined machine-made and hand-made processes, which turned the impression of uninteresting products made by machines…

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

The Noodle Extruder can be used to produce Spaghetti, Noodle and Noodles with Multi Structured, such as heart-shaped, fish-shaped, dumbbell-shaped, and…

The Best Selection - Get Started with Us to Discuss Your Needs

Automatic Encrusting and Forming Machine

Automatic Encrusting And Forming Machine can make either patterned or non-patterned products with a simple change of shutters; it can make either two colors or solid color with a simply change of dough hoppers. Not only the products with red bean paste, meat stuffing, or sesame paste but also plain products are producible. In conclusion, SD-97W can make dozens of ethnic foods such as meat bun, steamed bun, maamoul, meat pie, pan fried stuffed bun, mochi, crystal dumpling. Their look and taste are able to compare with handmade ones. The IoT (Internet of Things) have been installed to ensure that the production can be overseen by managers in real time on a mobile device, and the data can be collected and processed through Big Data Analytics to support decision making. We have also installed a maintenance reminder program to ensure consistent productivity. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More Info Compare searies machineCompare with Similar Models

| Model no | Automatic Encrusting and Forming Machine SD-97W | Automatic Encrusting and Forming Machine SD-97L | Automatic Table-Type Encrusting and Forming Machine SD-97SS |

|---|---|---|---|

| Description | Two color wrapper is available | Max. product weight up to 200 grams | Most compact machine |

| Capacity | 1,000 - 4,000 pcs/hr | 2,400 - 4,800 pcs/hr | 600 - 3,600 pcs/hr |

| Weight | 10 - 70 g/pc | 40 - 200 g/pc | 10 - 60 g/pc |

| More Info | More Info | More Info |

Specifications

Capacity: 4,000 pcs/hr or 90 kg/hr

Features

- The built-in IoT function integrates the automated production line, and you can access this through remote monitoring via ANKO’s IoT dashboard.

- Voltage can be designated.

- The thickness of sesame ball and the amount of filling can be adjusted by parameter setting.

- The shape of sesame ball can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

- Downloads

- Best Selling

- Related Food Solutions Type