Taiwanese Meat Ball

Taiwanese Meat Ball Machine and Production Solutions

Model no : SOL-TMB-0-1

Bawan (肉圓) is a type of Taiwanese Meat Ball that is typically sold as a savory street snack, and it has recently become a popular frozen food product being exported to different countries. When distributing food products to wholesale and retail markets, it is important to have stable production quality and consistency to establish a good reputation. When transitioning from manual food production to automated, it is also important to consult with professionals and experts for the best results. ANKO has assisted many clients develop new “Bawan” production lines and our engineers have designed the perfect machine to make Taiwanese Meat Balls with a translucent skin. Please feel free to contact us and our Professional Consultants will send you a quotation and provide you with more information.

Producing Artisanal Bawan with Automated Food Machine

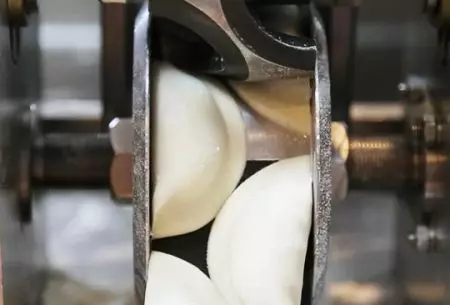

ANKO SD-97W Automatic Encrusting and Forming Machine is compact in size (1.5 square meters) and has the capacity of producing 4,000 pieces of “Bawan” per hour. This machine only takes one person to operate, and it is easy to clean and maintain. To make Taiwanese Meat Balls, first step is to mix sweet potato starch, yam flour, rice flour and tapioca starch into a highly viscous paste; and then the traditional filling usually contains pork, bamboo shoot, mushroom, fried shallots, and seasoning.

ANKO machine has a unique design that can process the highly viscos paste, also to extrude, coat and form each Taiwanese Meat Ball perfectly and efficiently. ANKO’s professional food scientist can assist our clients with recipe development and transform from manual to automated food production, and make sure the product taste and texture remain the same. ANKO can also provide production planning advice, production line implementation and staff management, as well as processing equipment configuration.

SD-97W has a built-in Internet of Things (IoT) system which is connected to the Big Data Analytics. It collects data from each production and be utilized with extended applications to manage production balances, warehousing and scheduling. This technology offers you full control over production by “monitoring the machine operational status, maintenance machine lifespan, and digital production management”. An alarm will inform you the exact part that needs inspection to reduce any possible risks.

Food's Gallery

- Taiwanese meat ball filling is densely packed

- Fully filled taiwanese meat ball

1

Filling / Forming

- Forming

Case Studies

Kibe Automatic Production Equipment Designed for a French Company

Kibe (Kibbeh) is one of the basic cuisines in the Middle East, so the high demand has made client's business booming. However, his employees couldn't meet…

Automatic Vegetarian Dumpling Machine for a Taiwanese Company

Vegetarian foods are the client's primary products. The manual production no longer meets the growing demands, in order to boost productivity…

Stuffed Cassava Ball Machinery Design for a Peruvian Company

The client's stuffed cassava products had been made by hand. When the demand increased to a certain amount, he was seeking a machine…

Automatic Wonton Production Line Design for a British Company

The client combined machine-made and hand-made processes, which turned the impression of uninteresting products made by machines…

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

In Taiwan, most traditional noodle machines have good productivity but are limited in the types of noodles. Hence, ANKO developed…

Soup Dumping Automatic Production Equipment Designed to Solve Insufficient Capacity and Product Quality

The company owns a Cantonese restaurant serving handmade dim sum. With business growth, a lack of supply…

Automatic Steamed Custard Bun Machine Achieves the Demand for a Taiwanese Company

The client used to make their food products by hand. With more and more restaurants opened, the continuing growth in demand…

The Best Selection - Get Started with Us to Discuss Your Needs

Automatic Encrusting and Forming Machine

Automatic Encrusting And Forming Machine can make either patterned or non-patterned products with a simple change of shutters; it can make either two colors or solid color with a simply change of dough hoppers. Not only the products with red bean paste, meat stuffing, or sesame paste but also plain products are producible. In conclusion, SD-97W can make dozens of ethnic foods such as meat bun, steamed bun, maamoul, meat pie, pan fried stuffed bun, mochi, crystal dumpling. Their look and taste are able to compare with handmade ones. The IoT (Internet of Things) have been installed to ensure that the production can be overseen by managers in real time on a mobile device, and the data can be collected and processed through Big Data Analytics to support decision making. We have also installed a maintenance reminder program to ensure consistent productivity. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More Info Compare searies machineCompare with Similar Models

| Model no | Automatic Encrusting and Forming Machine SD-97W | Automatic Encrusting and Forming Machine SD-97L | Automatic Table-Type Encrusting and Forming Machine SD-97SS |

|---|---|---|---|

| Description | Two color wrapper is available | Max. product weight up to 200 grams | Most compact machine |

| Capacity | 1,000 - 4,000 pcs/hr | 2,400 - 4,800 pcs/hr | 600 - 3,600 pcs/hr |

| Weight | 10 - 70 g/pc | 40 - 200 g/pc | 10 - 60 g/pc |

| More Info | More Info | More Info |

Specifications

Capacity: 4,000 pcs/hr or 90 kg/hr

Features

- The built-in IoT function integrates the automated production line, and you can access this through remote monitoring via ANKO’s IoT dashboard.

- Voltage can be designated.

- The thickness of taiwanese meat ball wrapper and the amount of filling can be adjusted by parameter setting.

- The shape of taiwanese meat ball can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

- Downloads

- Best Selling

- Related Food Solutions Type