10 Result(s) for Machines: Roll

Multipurpose Filling and Forming Machine

- Tasty Appearance as handmade look

- 2,000 - 12,000 pcs/hr

- 13 - 100 g/pc

Multipurpose Filling and Forming Machine

- A wide range of standard rotary molds are available

- 2,000 - 10,000 pcs/hr

- 13 - 100 g/pc

Double-Line Multipurpose Filling and Forming Machine

- Highest production capacity

- 4,000 - 20,000 pcs/hr

- 13 - 100 g/pc

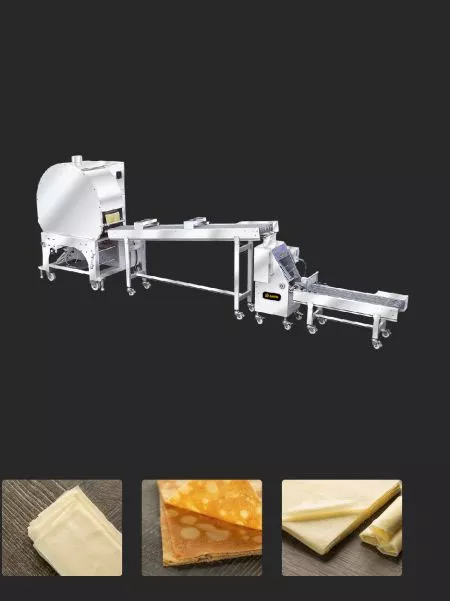

Automatic Spring Roll and Samosa Pastry Sheet Machine

- High capacity and uniform products

- 2,700 pcs/hr, 9 m/min (200 x 200 mm)

- -

Finger Spring Roll Production Line

- Can produce a wide variety of products

- 1,600 - 6,400 pcs/hr

- -

Vietnamese Rice Paper Spring Roll Machine

- Equipped with water spraying, steaming, softening, and filling devices

- 1,200 - 1,500 pcs/hr

- -

Semi-Automatic Spring Roll and Samosa Production Line

- High capacity

- 2,400 pcs/hr (200 mm x 200 mm)

- 30 - 80 g

19 Result(s) for Food Solutions: Roll

10 Result(s) for Other Pages: Roll

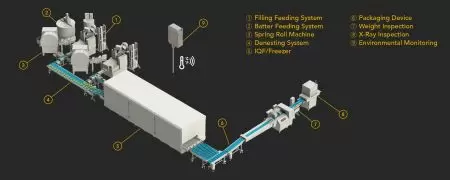

Integrated Spring Roll Production Line

ANKO's "Integrated Spring Roll Production Line" is expandable, highly automated, and performs at great production efficiency. This unique design was developed and refined from our extensive experience with automated Spring Roll production lines. Each production process has been modularized and seamlessly connected to create ultra-high production efficiency with minimal labor requirements. The result is high product quality combined with ultimate production consistency. Based on each client's specific product requirements, we can customize production lines to meet diversified specifications. To ensure production accuracy and consistency, ANKO modularized and automatically controls eight major components in the production line, including the filling conveying, Spring Roll forming, quick freezing, packaging, weighing, and the X-Ray inspection machines. Our machines are programmed to produce standardized 10cm Spring Rolls, and ANKO can also customize Mini Spring Rolls production solutions to meet specific product requirements. Click the button below to complete the form and provide us with your specific production requirements. Click the button below to complete the form to receive more information.

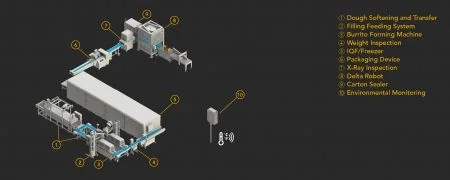

Integrated Burrito Production Line

ANKO’s integrated burrito production line includes ten stations—from dough preparation, filling, rolling, cooling, freezing, weighing, X-ray inspection, to packaging and case sealing—each equipped with dedicated machines. With just 4–5 operators, it ensures stable, high-capacity burrito production. Designed for high capacity with minimum manpower, it's the ideal solution for the burrito market in Europe and the Americas. Click the button below to complete the form to receive more information.

Integrated Plain Paratha Production Line

ANKO’s Integrated Plain Paratha Production Line is designed for high-quality, multi-layer flatbreads. By loading dough and butter into the hopper, the line fully automates pressing, oil-layer folding, rolling, shaping, and flattening—no manual work required. With a film-pressing system, it can produce up to 32-layer round parathas, then automatically film and stack them. The full line connects 11 stations, including dough feeding, forming, aligning, filming, packaging, weight checking, freezing, metal detection, robotic picking, and carton sealing, plus environmental monitoring. With production capacity reaching up to 10,800 pieces per hour, this solution is ideal for frozen flatbread manufacturers and global food factories seeking stable, high-speed production with reduced labor.

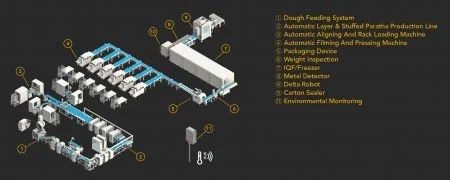

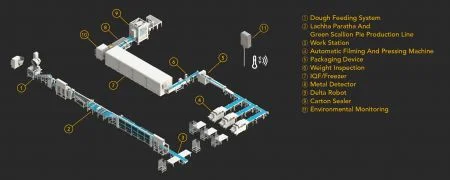

Integrated Lachha Paratha Production Line

ANKO's Integrated Lachha Paratha Production Line is designed for high-volume production of frozen layered flatbreads. The line connects 11 stations—from dough feeding, forming, workstation, automatic filming and pressing, packaging, weight checking, freezing, and metal detection to robotic picking, carton sealing, and environmental monitoring—covering every step from preparation to final packaging. Its stretching mechanism creates ultra-thin, semi-transparent dough sheets down to 0.8 mm, stacked into flaky, crispy Lachha Paratha or scallion pies. Once dough and ingredients are loaded, the system automatically sprinkles fillings, rests the dough, rolls, and shapes the product. A 35 meters resting unit provides about 10 minutes of dough relaxation and fat setting, ensuring well-defined layers and ideal texture. Requiring only 13 operators, this fully automated solution is ideal for frozen food manufacturers and global food brands seeking high-capacity, stable, and labor-saving production lines. Click the button below to complete the form to receive more information.

Missed Spring Roll Demo? Fill out the form for the replay!

ANKO's SR-27 online Spring Roll Production Demo was a great success! Thanks to all who participated and witnessed the highly efficient SR-27 Spring Roll Machine in action. This machine produces one Spring Roll every 1.4 seconds! ANKO's team of experts answered various questions regarding the Spring Roll machine. These included the best configurations for a complete automated Spring Roll production line, the types of fillings the machine can handle, appropriate factory sizes, machine warranties, and more.

Expand Your Business with Efficient Spring Roll Production Solutions

Join us for an exclusive LIVE demonstration of our SR-27 Spring Roll Production Line. We will guide you through the efficient production process and show you how ANKO’s advanced Spring Roll machine can benefit your food production business.

Crafting Perfect Vegetarian Spring Rolls with ANKO's Automated Food Machine

ANKO Food Machine Company is a world-renowned automated food machinery manufacturer and a professional consulting company for automated ethnic food production. In 2023, ANKO will be proudly launching our brand new “SR-27 Automatic Spring Roll Production Line”. It is suitable for large food factories, central kitchens, and large-scale manufacturers to help resolve production issues related to the global labor shortage and rising wages. ANKO’s SR-27 has the capacity of producing 2,700 Spring Rolls per hour, and the unique filling system can process and extrude a wide range of ingredients. After loading the hoppers with raw materials, the automated production begins with a simple click. All the parts that have direct contact with food ingredients can be cleaned thoroughly and easily with water.

Pop-Up Restaurants - A Creative New Food Service Model

The Global Food and Hospitality Industries have been dramatically affected by COVID-19 over the past few years. Many food companies and restaurants have to adapt and change to create more innovative dining experiences that are cost effective and this has inspired many interesting Pop-Up Restaurants.

2016 Vietnam Fisheries International Exhibition

Products made of seafood and fish are numerous. ANKO's HLT-series Multipurpose Filling & Forming Machine will be on display at the booth. HLT-series are suitable for various kinds of fillings and wrappers and can work with different forming molds to produce a variety of food products, which have gained favor with many food manufacturers. Welcome to have free catalogues, join us for machine introductions and demonstrations from our professional engineers. ANKO is worthy of your trust. Seeing is believing. In addition to food processing machines, ANKO offers turnkey projects to integrate food preparation and product packaging equipment into a production line, which greatly saves purchaser's time and cost. If you plan to visit our booth, please click RESERVATION icon to fill in the following form. We will set up a visit and assign a professional engineer to assist you.