Spring Roll Wrapper

Your Spring Roll Wrapper Production Planning And Spring Roll Wrapper Recipe Consultant.

Model no : SOL-SRP-S-1

ANKO’s “spring roll wrapper production solution” is a one-stop solution that combines the provision of equipment and comprehensive planning service. According to your conditions, such as factory size, production plan, and market expansion strategy, ANKO will develop your own solution. ANKO’s “spring roll wrapper production solution”provides not only complete machines for preparing, forming, and packaging, but also a wide range of consulting services, including optimization of production flow, factory layout planning, and staff deployment, to help you introduce more stable and efficient automatic production. In the solution below, the machines can be adjusted in model and quantity according to real production needs. Want to get a quick quote and consultant? Please click the button below and fill out the form.

About Spring Roll Wrapper Production Solution

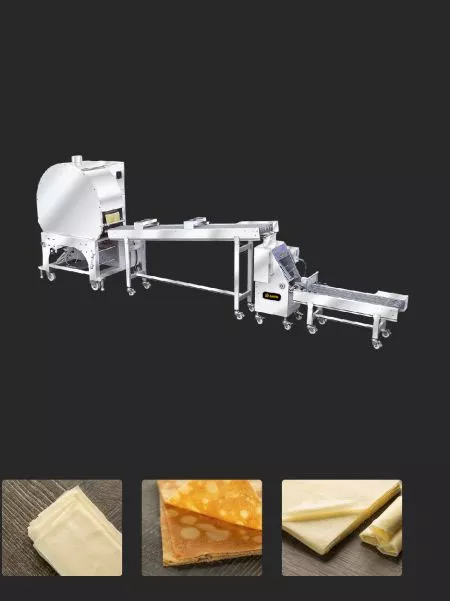

With ANKO Automatic Spring Roll Wrapper Sheet Machine, the automation can simplify manual production process to efficiently increase your production capacity and maintain the quality of final products. You just have to put prepared batter into the tank and the machine can automatically make spring roll wrappers by baking, cutting, and stacking for packaging and selling. The baking drum of the machine has a micro-computer temperature controller with an accuracy of ±1℃ to ensure that spring roll pastries are evenly baked and have consistent quality.

Food's Gallery

- Attaching an Spring Roll to complete an automatic Spring Roll production line

- Suitable for various recipes to make soft and springy Spring Roll Wrappers

- It can also produce Spring Roll Wrappers for frying

- Spring Rolls are made firmly

- Both ends of the Spring Rolls are perfectly folded in

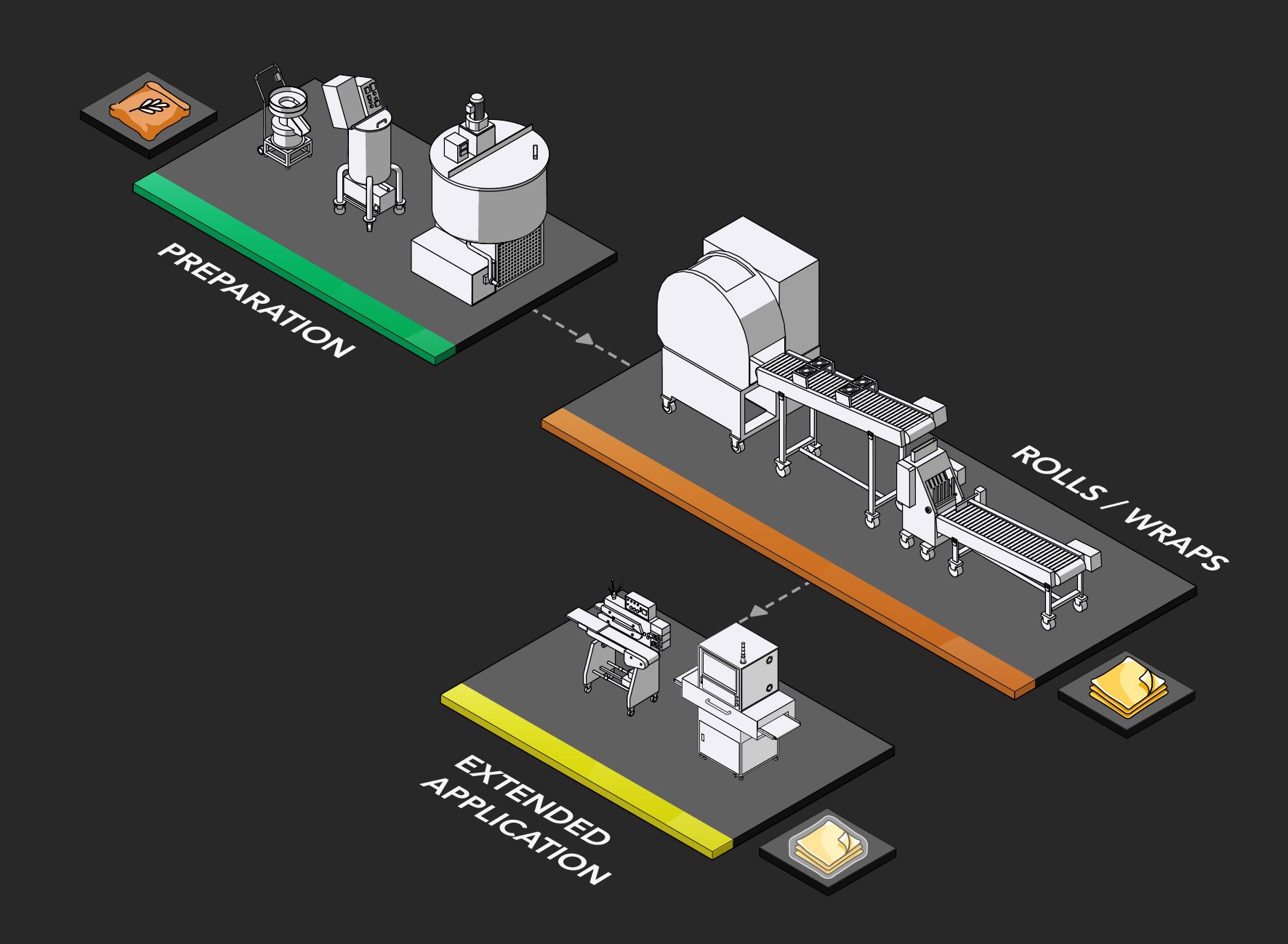

Turnkey and Production Planning

1

Preparation

- Sieving

- Mixing

2

Rolls / Wraps

- Spring Roll Equipment

3

Extended Application

- Sealing

Sealing

The spring roll wrapper production solution includes machines for packaging to facilitate the entire process from producing to packaging. According to your factory layout and production needs, ANKO’s sales engineers can help you arrange related machines, such as cutting machine, mincer, and seasoning machine, and provide the most suitable solution.

- Quality Control

Quality Control

ANKO’s X-Ray Inspection Machine can detect various metals, bones, glass, and other foreign objects during food production; even something as small as 0.4mm. The machine is equipped with luminating and buzzer warnings to ensure real-time contaminant detection, prevent artificial hazards, and increase overall product quality.

Case Studies

Machinery Design for a South African Company

The client's businesses, establishing in South Africa, extend from producing frozen food, baking products to central kitchen and catering service.…

Machinery Design for a Thai Company

The client has production lines for bakery and ethnic food, including baozi, siomay, hargao, bread, etc. In order…

For an Indian Machinery Design

The client is strict to control quality to ensure that consumers enjoy food with good quality and receive the best service. …

Machinery Design for a Spanish company

The company is well-known in Europe, mainly selling Chinese food. They always take client's health as priority…

Machinery Design for American Company

The company sells processing aquatic food products to all kinds of supermarkets in western countries. …

The Best Selection - Get Started with Us to Discuss Your Needs

Automatic Spring Roll and Samosa Pastry Sheet Machine

SRP Automatic Spring Roll and Samosa Pastry Sheet Machine is a food processing machine for automatically producing spring roll wrapper, samosa pastry, egg roll pastry, and even crepe. Simply prepare batter and the SRP Series will automatically finish the rest of steps, including baking, cutting, counting, and stacking. Finally, the baked pastries are nicely stacked in piles, ready to be packed, frozen, and sold at any time. It is also a samosa pastry machine. Samosa pastries can be made with the same process except that the way of cutting is different. Cutter can be customized as required. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More InfoSpecifications

Capacity:36 kg/hr or 2,400 pc/hr

*Based on 15-gram spring roll pastry

Features

- Voltage can be designated.

- Special batter storing, cooling & resting tank can keep batter flowing stably to ensure the spring roll pastries have fine quality.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

What services and benefits are covered in the solution?

Custom-made spring roll wrapper production solution saves your time and makes you get all equipment from one single place

Different processing machines, from mixer, forming machine, to packing and freezing machines, comprises a comprehensive automatic spring roll wrapper production line. ANKO provides solution service to save you searching and inquiring machines one by one. To ensure that the solution proposal is suitable for you, you could run your product through our machines in our well-equipped food lab. After your machines arrived, we can provide installation and training services. The costs from contacting each suppliers and other expenses will not bother you.

ANKO provides industry-leading integrated services in spring roll wrapper machines

ANKO's consulting team can help you compare different models to find the most appropriate spring roll wrapper machine and install an affordable production line based on your needs and required production capacity. Also, we provide exclusive assessment and integration suggestions according to current conditions, workflow, factory layout, estimated time to put machine into operation, recipes, and other issues. The integrated and specialist service can greatly reduce the risk of purchase and, to meet your requirements, give you the best solution to keep smooth operation anytime.

Maintain spring roll wrapper production efficiency, save time on primary decision

Many owners might have unpleasant experience of contacting customer service for spring roll wrapper machine repair, especially when a problem is handled by different customer service specialists. The long process might affect spring roll wrapper production capacity and lead to unexpected losses caused by shutdown and delivery delays. Hand over your concerns to ANKO! We provide a custom-made one-stop solution for you and assign a specific person to help all things from purchase to repair. Moreover, our comprehensive database records all your machine details to reduce the risks of loss someday.

45 years' experience in selling spring roll wrapper machines all over the world, providing high-quality food recipe and adjustment suggestions

How can the machine-made spring roll wrappers be as delicious as the handmade ones? ANKO has a professional team and food researchers to offer customers the best recipes and adjustment suggestions. Currently, we have sold our products to more than 100 countries. ANKO's food machines can make a wide variety of food, including Chinese, Indian, the Middle Eastern, Latin American, European, and other ethnic food. With a wealth of experience, ANKO is confident of making the most suitable suggestions for your spring roll wrapper recipe and helps you be unbeatable in the market.

- Best Selling

- Related Food Solutions Type