Vietnamese Spring Roll

Vietnamese Spring Roll Machine and Production Solutions

Model no : SOL-VSR-0-1

Vietnamese Spring Rolls are made with gluten-free rice paper and various ingredients into a delicious appetizer. A gluten-free diet can help people with celiac disease to manage their symptoms, and this diet is closely associated with many other benefits which has prompted the global gluten-free food market to expand each year. ANKO has developed a Vietnamese Spring Roll Machine to efficiently produce gluten-free Spring Rolls to fulfill this increasing market demand.

Producing Vietnamese Spring Rolls with Quantity and Quality

“Cha Gio” is also known as the Vietnamese deep-fried Spring Rolls; they are usually made with a rice paper (bánh tráng) and filled with a variety of ingredients such as ground pork, chicken or shrimp pastes, vegetables, and mushrooms; then wrapped into individual rolls to be deep-fried into golden brown and crispy snacks. This dish is usually served with a Vietnamese dipping sauce called “nuoc cham”. Cha Gio is a popular snack in Vietnam, and it has become a trendy exotic appetizer in France, the Unite States, and Australia.

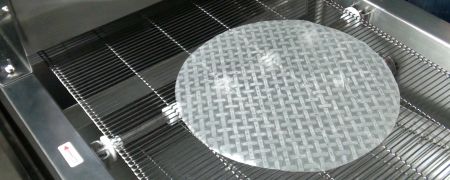

ANKO RPS Series Vietnamese Rice Paper Spring Roll Machine is designed to initially steam the rice papers, and then extrude the premixed filling onto the rice paper ready to be wrapped into individual Spring Rolls by hand. Additionally, an automatic rice paper dispenser, filling mixer, or rice paper steaming and filling extruding device is available; as well as packaging equipment that can be added to your customized production line for higher quality and productivity. ANKO can also assist clients with recipes and parameter settings to perfect an automated Vietnamese Spring Roll production line.

Food's Gallery

- Deep-fried spring rolls

- Spring rolls are perfectly sealed

- Fully filled spring rolls

1

Rolls / Wraps

- Sheeting / Wrapping

Sheeting / Wrapping

The key to Vietnamese Spring Rolls’ quality control is the consistency of the rice paper. ANKO’s machine is equipped with a water sprinkler, steamer, and filling extruding device to ensure the consistency of the rice papers and the amount of filling that is placed on the rice paper. Employees can simply focus on the wrapping process, and the automated rice paper suction device can be used to place rice papers on the production line to increase productivity.

Case Studies

Automatic Spring Roll Production Line for a Canadian Company

The client runs chain restaurants and receives frozen food orders from supermarkets in Canada. Because of increasing demands…

Paneer Spring Roll Automatic Production Equipment Designed with Special Filling Device

Years ago, the client bought SR-24 spring roll machine from ANKO. This time, he placed another order because he trusts ANKO…

ANKO Spring Roll Machinery Design for a Jordanian Company

At the end of Ramadan, the client received a large number of spring roll orders. He uses three semi-automatic spring roll production machines…

Cheese Spring Roll Automatic Equipment Designed with a Customized Filling Mold

The company's cheese roll features its thin pastry made of batter. This time, through ANKO's customized services and trials…

Automatic Spring Roll Pastry Machinery Solved Labor Shortage for a South African Company

With the gourmet spring roll was getting more popular, insufficient employees could not meet higher demands…

Spring Roll Pastry Machinery Design For an Indian Company

The client is strict to control quality to ensure that consumers enjoy food with good quality and receive the best service. Due to business expansion…

Vegetarian Spring Roll Production Line Design for a German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to devote extra time on reprocessing…

The Best Selection - Get Started with Us to Discuss Your Needs

Vietnamese Rice Paper Spring Roll Machine

The RPS Series is designed with water spraying, steaming, softening, and filling devices, so workers only need to put rice papers on the conveyor and fold the spring rolls. You can also add a lifting device to place rice papers automatically. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More InfoSpecifications

Capacity:1,500 pcs/hr

Features

- Voltage can be designated.

- The amount of filling can be adjusted by parameter setting.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

- Downloads

- Best Selling

- Related Food Solutions Type