Finger Spring Roll Production Line

Finger Spring Roll Machine

Model no : FSP

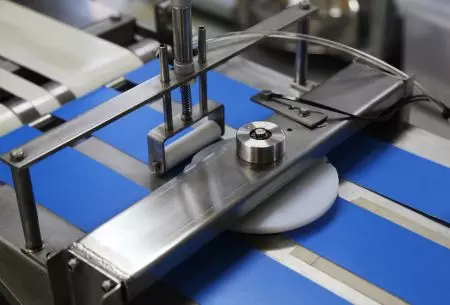

The FSP is designed to make finger spring rolls. After pouring prepared batter and filling into the hoppers, the FSP bakes the batter into a pastry belt at 150-180°C, cools it as conveying, extrudes filling, rolls it over the filling, and cut the filled cylinder into small rolls. Up to 6,400 rolls can be made in an hour. Want to get a quick quote and consultant? Please click the button below and fill out the form.

How It Works

Food's Gallery

- Open-ended spring rolls

- Spring rolls can be deep-fried

- Spring rolls are evenly divided

Specifications

- Dimensions: 6,500 (L) x 1,500 (W) x 2,400 (H) mm

- Power: 35 kW

- Capacity: 1,600–6,400 pcs/hr

- Pastry thickness: 0.4–0.7 mm

- Finger spring roll size: 75–300 (L) x 15–25 (Dia.) mm

- Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

-

Advanced equipment with safe and hygienic design.Easy to disassemble for maintenance and cleaning.All parts in contact with food are made of food grade stainless steel.All the electronic components meet the international standards.

-

A wide variety of products.Pastry: spring roll pastry, crepe, egg roll sheet, etc.Filling: meat, cheese, bean paste, chocolate, date paste, jam, etc.Offer variety of finger foods and snacks.

Case Studies

Semi-Automatic Vegetarian Spring Roll Production Line – Machinery Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

Spring Roll Production Line for a Canadian Company

In Canada, the frozen food market is in the keen competition…

Spring Roll Production Line for American Company

ANKO have abundant knowledge in food ingredients and recipes…

Cheese Spring Roll Automatic Equipment

Compare to Chinese spring roll, they are quite similar in the handmade production and crispy taste…

Spring roll Production Line for Jordanian Company

How to determine the stickiness of stuffing which affect the depositor stability…

Paneer Spring Roll Automatic Equipment

High moisture content in the filling affected machine operation.…

- Downloads

- Best Selling

FAQ

A commercial Finger Spring Roll Machine is a high-value investment for food factories, restaurants, and frozen food manufacturers. The FSP automates pastry heating, sheeting, filling, and rolling, greatly reducing labor costs, boosting output, and ensuring consistent quality—far more efficient than manual production. Many ANKO clients have expanded from small shops or food carts to major restaurant chains, proving that ANKO equipment delivers long-term production benefits and competitive growth.

Yes. Purchasing food machinery includes full service before and after installation. We provide machine testing, product trial runs, and consultation through local offices and distributors worldwide, including the US, Europe, and Asia. After purchase, buyers receive installation, operator training, and after-sales service to ensure stable production. In addition, modular and partially customized options allow manufacturers to adjust machine settings to create different product textures, shapes, and flavors efficiently.

The price of a commercial Finger Spring Roll Machine depends on the level of automation and customization required. The production line can be paired with vegetable cutters, mixers, robotic pick-and-place systems, frying machines, and other downstream equipment, allowing frozen food manufacturers and restaurant chains to purchase a complete one-stop solution. In addition to supplying machinery, ANKO also provides pre-sales consultation, operator training, and after-sales support to ensure fair pricing and reliable production performance throughout the entire process.