Commercial Noodle Machine

Noodle Extruder

Model no : NDL-100

ANKO’s Noodle Extruder machine is co-created with Taiwan’s Food Industry Research and Development Institute. This innovative commercial noodle machine can be used to produce large quantities of noodles with unique shapes, such as heart-shaped, fish-shaped and dumbbell-shaped, as well as triangle-shaped noodles that increase the surface area to help absorb sauces after cooking. This machine is only 1.3 square meters (14 square foot) making it suitable for specialty noodle producers, central kitchens, chain restaurants, and food factories of any size. The automated noodle production starts after the dough is loaded in the hopper and then the machine’s automatic portioning function does the rest. Productivity for 3mm diameter noodles can reach up to 100kg per hour. Want to get a quick quote and consultant? Please click the button below and fill out the form.

How It Works

Food's Gallery

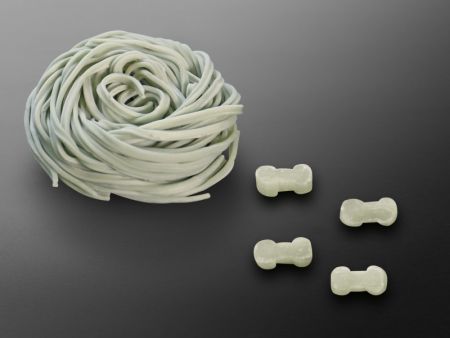

- Circle-shaped noodle

- Triangle-shaped noodle

- Dumbbell-shaped noodle

- Fish-shaped noodle

- Heart-shaped noodle

- Fusilli

- Mafaldine

Optional Accessories

Noodle mold、CE kit

Noodle molds

| Circle mold (2 mm) | Circle mold (3 mm) | Heart mold | Dumbbell mold |

|  |  |  |

| Triangular mold | Fish-shaped mold | Fusilli mold | Mafaldine mold |

|  |  |  |

In addition, we also provide Mold Customization, please click, click Learn More>

Specifications

- Dimensions: 1,580 (L) x 850 (W) x 1,720 (H) mm

- Power: 6.1 kW

- Capacity: 100 kg/hr (Based on 3mm diameter noodle)

- Product name: Noodle, Spaghetti

- Optional accessories: Noodle mold, CE kit

- Weight (net): 800 kg

- Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

-

Customized Multi Structure Noodle MoldsCustom made noodle products with unique shapes that can help increase brand recognition for our clients.

-

Quickly switch noodle productionSimply change a mold, easy to produce various noodle products.

-

Processes a Wide Range of IngredientsWorks with gluten-free or protein-based dough and pastes, such as lentil flour, or fish pastes.

-

Compact in Size1.3 square meter (14 square foot) suitable for different production spaces.

-

Easy to OperateIt has a user-friendly interface and is installed with various parameter settings.

-

Dough Cooling SystemUses cold water to keep the dough under 35 °C (95 °F) for best product consistency and texture.

-

User-Friendly DesignOperational personnel can manage production while standing or sitting. Additional conveyor belts and other devices can be connected for further processing.

Case Studies

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

In Taiwan, most traditional noodle machines have good productivity but are limited in the types of noodles…

Additive-Free Dumpling Machinery Design for a Singaporean Company

A client and her partners started a business in Singapore. These entrepreneurs later decided to invest in the Chinese Dim Sum…

Shanghai Wonton Machine Design to Solve Labor Shortage

ANKO customized two rotary molds to help the client mass-produce shanghai wontons that were complicated to fold by hand…

Multipurpose Filling & Forming Machinery Design for a Taiwanese Company

Potsticker is popular in Great China area, so the supply was often unable to meet the demand. Thus, the client decided to manufacture with machine…

Stuffed Paratha Machine-Machinery Design for Indian Company

The client planned to expand into the U.S. market. He compared ANKO with other food machine suppliers and found ANKO is superior…

Semi-Automatic Vegetarian Spring Roll Production Line – Machinery Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

Tang Yuan Automatic Encrusting and Forming Machine for a Hong Kong Company

With current frozen equipment and packaging machinery, they would like to increase efficiency and develop other…

- Downloads

- Best Selling

FAQ

A Commercial Noodle Machine is a valuable investment for food factories, restaurants, and frozen food manufacturers. The NDL-100 significantly reducing labor costs, increasing output, and maintaining consistent quality—far more efficient than manual production. Many ANKO clients have grown from small shops or food carts into major restaurant chains, proving that ANKO equipment delivers long-term production benefits, higher efficiency, and competitive growth in large-scale shumai production.

Yes. Purchasing food machinery includes full service before and after installation. We provide machine testing, product trial runs, and consultation through local offices and distributors worldwide, including the US, Europe, and Asia. After purchase, buyers receive installation, operator training, and after-sales service to ensure stable production. In addition, modular and partially customized options allow manufacturers to adjust machine settings to create different product textures, shapes, and flavors efficiently.

The price of a Commercial Noodle Machine depends on its level of automation and customization requirements. ANKO machines can be integrated with dough mixers, robotic arms for pick-and-place, and other front- or end-of-line equipment. For frozen food factories and chain restaurants, ANKO provides a one-stop solution where they can obtain all the machines they need.