Spring Roll

Spring Roll Production Line Planning and Recipe Consultation

Model no : SOL-SPR-S-1

ANKO has developed a powerful Spring Roll Production Solution - “SR-27 Spring Roll Production Line”. This machine is designed with a unique filling and forming mechanism that mimic handmade procedures and has an impressive efficiency to output perfect Spring Rolls at a rate of 1.4 seconds per piece. ANKO also provides a production line implementing configuration service, and Spring Roll wrapper recipes to ensure the success of your food production business. Please click on the link below for more information, and our professional consultants will contact you with assistance and special offers.

About Spring Roll Production Solution

ANKO SR-27 Spring Roll Production Line has the capacity of producing 2,700 pieces per hour. The unique patented folding mechanism simulates a hand rolling process to form perfect Spring Rolls. The filling system is able process a wide variety of ingredients, such as mushroom, bean sprouts, shredded cabbage, and carrots, as well as meat and seafood. It can handle large pieces of foods that are 10mm in diameter, or pieces that are within the 30x10x5mm range and still retain the ingredient’s original texture in the Spring Roll filling. Our machines are able to produce Mini Spring Rolls at 7cm in length.

SR-27 is suitable for food factories, central kitchens, and food manufactures that need to produce Spring Rolls in large quantities. Based on whether the Spring Rolls are made to be frozen, deep fried, or served right away at room temperature, ANKO can help by adjusting the recipes; accordingly, and produce wrappers with different elasticity, density, and moisture content. Our machine is user friendly and designed with an intuitive control panel, all you need to do is to load the hoppers with batter and filling ingredients, then enter the parameter settings, and the automated production can begin.

Food's Gallery

- Great quality Spring Roll made with highly efficient automated machinery

- It can produce Spring Rolls with different filling ingredients

- Diced apples filling

- The amount of filling can be adjusted according to product specifications

- Depending on client’s product requirements, ANKO’s machine can produce firmly packed or loosely filled Spring Rolls

- Spring Rolls made with a mixture of crunchy vegetable filling and meat which is not mushy

- The bean sprouts remain crisp and crunchy in vegan Spring Rolls

- These Spring Rolls are produced with automated food machines but taste like they are handmade

- Perfectly sealed

- The Spring Rolls resemble handmade products

- The Spring Rolls are densely filled and perfectly wrapped and sealed

- The size of the Spring Rolls are customizable

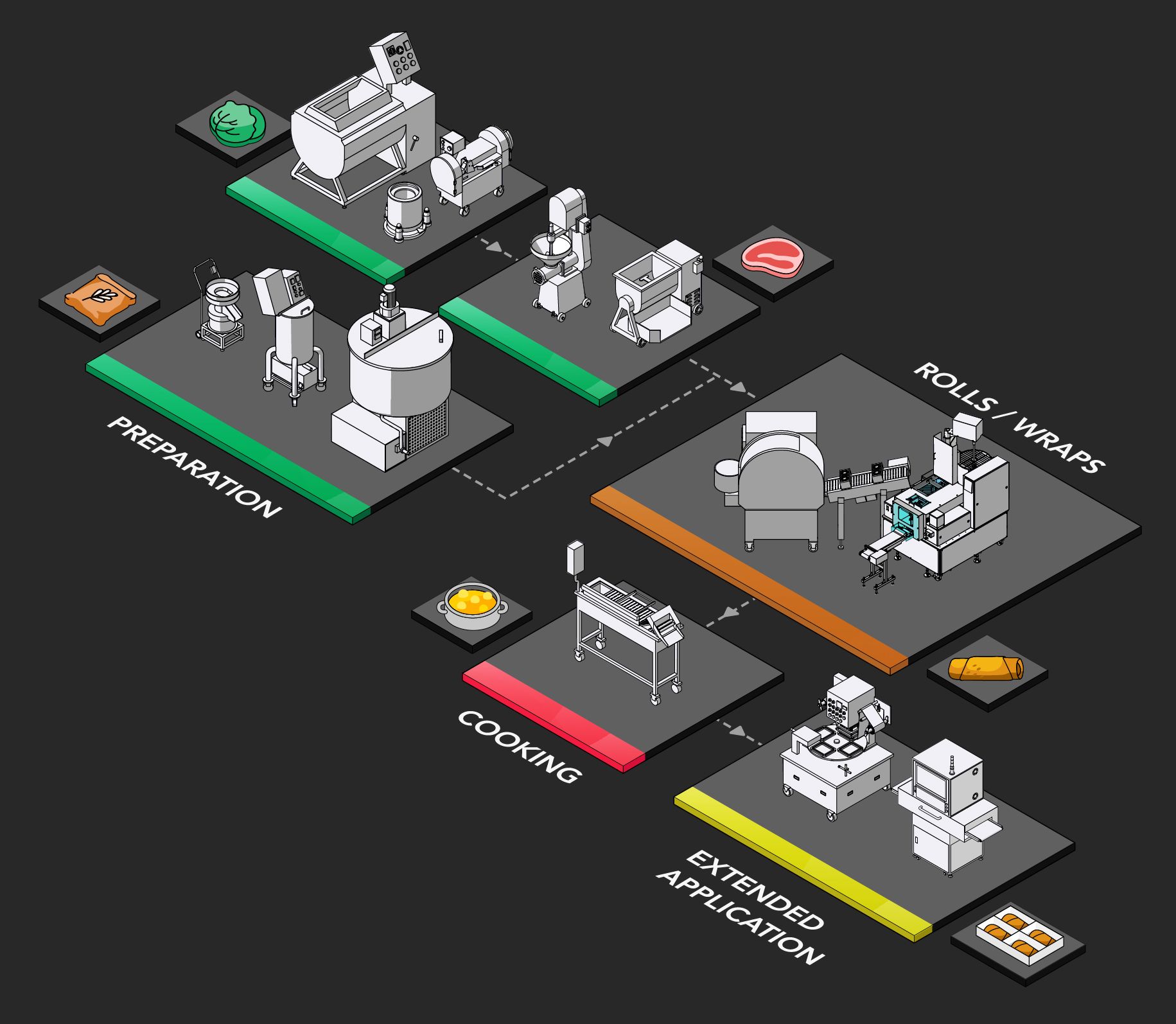

Turnkey and Production Planning

1

Preparation

- Sieving

- Mixing

- Vegetable Cleaning

- Vegetable Cutting

- Extracting

- Meat Mincing

- Seasoning

2

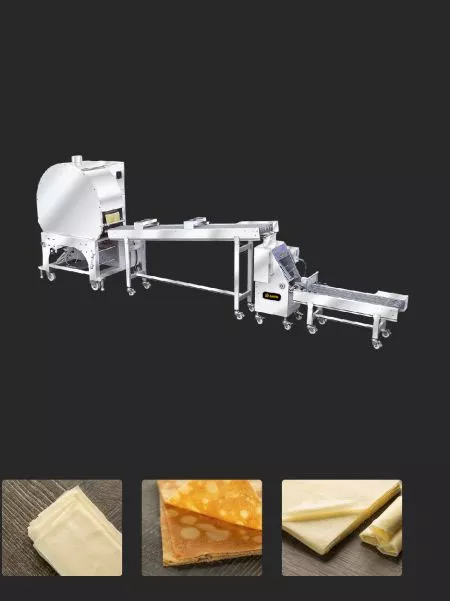

Rolls / Wraps

- Spring Roll Equipment

Spring Roll Equipment

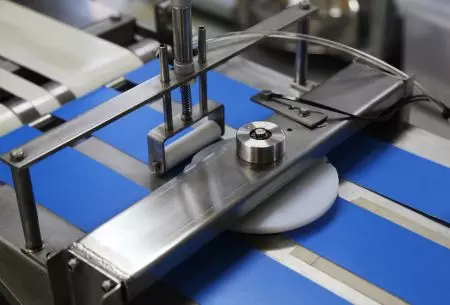

The forming machine is the major machine of the spring roll production line. The batter is spread onto a baking drum baking it into an extremely thin strip of spring roll wrapper. Then, it is cut into sheets of spring roll wrappers in the same size, and filled, folded, and rolled up into spring rolls with consistent quality.

3

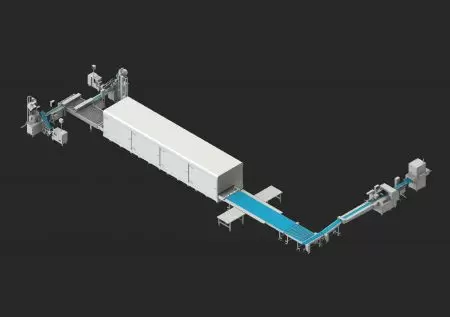

Cooking

- Frying

Frying

Based upon the spring roll deep-frying process and production capacity, we provide a variety of deep-frying machines. Oil temperature can be maintained at a certain degree by a digital controller to ensure every batch of spring rolls is heated uniformly. Oil tank is equipped a set of wire mesh conveyor to deliver deep-fried spring rolls out of the oil tank, which facilitate the next collecting and packing processes.

4

Extended Application

- Sealing

Sealing

ANKO's spring roll production solution includes machines for packing products fast and smoothly that make you quickly deliver them to every channel. Other machines, such as aligning machine, steamer, and freezer, are provided for you to choose. No matter what problems you have, ANKO's sales engineers will provide the most practical and affordable solution for you.

- Quality Control

Quality Control

ANKO’s X-Ray Inspection Machine can detect various metals, bones, glass, and other foreign objects during food production; even something as small as 0.4mm. The machine is equipped with luminating and buzzer warnings to ensure real-time contaminant detection, prevent artificial hazards, and increase overall product quality.

Case Studies

ANKO’s SR-27 Spring Roll Production Line – Designed for High Volume Spring Roll Producers

ANKO’s R&D team developed the SR-27 Spring Roll Production Line to meet client's increased production requirements…

Paneer Spring Roll Automatic Production Equipment Designed with Special Filling Device

Years ago, the client bought SR-24 spring roll machine from ANKO. This time, he placed another order because he trusts ANKO…

ANKO’s SR-24 Spring Roll Production Line is highly efficient and cost effective for North American markets

How to solve the stuffing was too loose to be rolled up firmly…

Semi-Automatic Vegetarian Spring Roll Production Line – Machinery Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

ANKO’s Spring Roll Production Line provides Solutions for a Jordanian Client’s Vegetable Spring Roll Manufacturing Issues

The shredded vegetable was too long and had too much juice that caused the problems of unstable feeding, so ANKO helped…

Cheese Spring Roll Automatic Equipment Designed with a Customized Filling Mold

The client requested that the final product should be within 30 g. In order to tailor to the client's requirement, we customized a filling mold…

ANKO assisted a client in Spain to establish a Food Safety Certified Spring Roll Wrapper Production Line

In order to observe local regulations of food safety, ANKO estimated the current space and suggested placing…

The Best Selection - Get Started with Us to Discuss Your Needs

Spring Roll Production Line

ANKO SR-27 Spring Roll Machine is designed with proprietary mechanisms and is highly productive. It takes just 1.4 seconds to produce a perfect Spring Roll with few employees required for the production process. The new model operates with high stability and the filling system is the perfect solution for processing a wide variety of filling ingredients, such as vegetarian, cooked meats, and potato filling with different textures. Depending on your product requirements, ANKO’s machine can produce wrappers with different length, textures and apply the proper amount of filling into the Spring Rolls. The most petit Spring Rolls our machines can produce are at 7cm in length. This machine can also create a variety of different Spring Rolls to be sold as a frozen packaged good or served deep-fried and ready to eat. The parts in contact with food products are water resistant and can be thoroughly and quickly cleaned on a daily basis. ANKO’s SR-27 Spring Roll Machine has a capacity producing of 2,700 pieces per hour, and is suitable for large food factories, central kitchens, and high-volume manufacturers.

More Info Compare searies machineCompare with Similar Models

| Model no | Spring Roll Production Line SR-27 | Automatic Spring Roll and Samosa Pastry Sheet Machine SRP Series | Semi-Automatic Spring Roll and Samosa Production Line SRPF Series |

|---|---|---|---|

| Description | Fully automatic production | High capacity and uniform products | High capacity |

| Capacity | 2,400–2,700 pcs/hr | 2,700 pcs/hr, 9 m/min (200 x 200 mm) | 2,400 pcs/hr (200 mm x 200 mm) |

| Weight | 22 - 50 g | - | 30 - 80 g |

| More Info | More Info | More Info |

Specifications

Capacity:2,700 pcs/hr

Features

- Voltage can be designated.

- Vegetable cutter can julienne, slice, dice vegetables.

- Special batter storing, cooling & resting tank keeps stirring batter to avoid lumps.

- Can work well with a maximum of 3-cm chopped vegetables. With a unique device, water can be extracted from cooked vegetables to retain texture.

- Can work well with a maximum of 1-cm meet dices and cooked filling such as loose cooked meat filling.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

What services and benefits are covered in the solution?

Custom-made spring roll production solution saves your time and makes you get all equipment from one single place

Different processing machines, from mixer, forming machine, to packing and freezing machines, comprises a comprehensive automatic spring roll production line. ANKO provides solution service to save you searching and inquiring machines one by one. To ensure that the solution proposal is suitable for you, you could run your product through our machines in our well-equipped food lab. After your machines arrived, we can provide installation and training services. The costs from contacting each suppliers and other expenses will not bother you.

ANKO provides industry-leading integrated services in spring roll machines

ANKO's consulting team can help you compare different models to find the most appropriate spring roll machine and install an affordable production line based on your needs and required production capacity. Also, we provide exclusive assessment and integration suggestions according to current conditions, workflow, factory layout, estimated time to put machine into operation, recipes, and other issues. The integrated and specialist service can greatly reduce the risk of purchase and, to meet your requirements, give you the best solution to keep smooth operation anytime.

One specialist solving all your problems, making spring roll machine repair easy and painless

If your spring roll production line consists of machines from different suppliers, when they need to be repaired, it will be troublesome and time-consuming. In the long term, a burden of management will increase. ANKO supplies all kinds of spring roll production facilities and comprehensive after-sales services. Even though the facilities and services cover a wide range from ingredient preparing, food forming, cooking, and packing machines as well as repair consultancy and service, all can be handled by one specialist to make machine repair and maintenance easy and painless.

45 years' experience in selling spring roll machines all over the world, providing high-quality food recipe and adjustment suggestions

How can the machine-made spring rolls be as delicious as the handmade ones? ANKO has a professional team and food researchers to offer customers the best recipes and adjustment suggestions. Currently, we have sold our products to more than 100 countries. ANKO's food machines can make a wide variety of food, including Chinese, Indian, the Middle Eastern, Latin American, European, and other ethnic food. With a wealth of experience, ANKO is confident of making the most suitable suggestions for your spring roll recipe and helps you be unbeatable in the market.

Would you like to find machines or integrated production line?

- Best Selling

- Related Food Solutions Type