Nalesniki

Your Nalesniki Production Planning And Nalesniki Recipe Consultant.

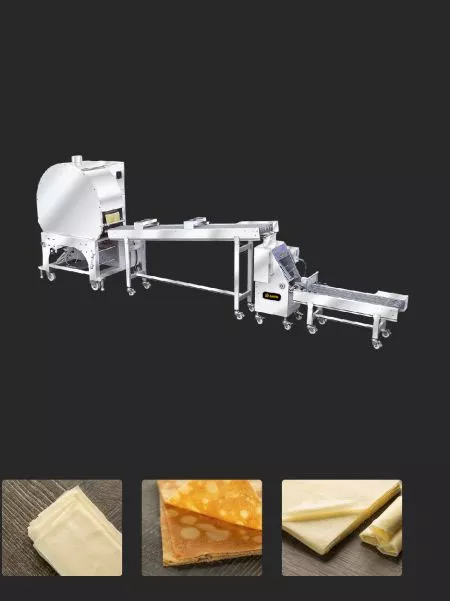

Model no : SOL-NLK-0-1

The Nalesniki production solution that ANKO launched provides one-stop production planning based on your factory layout and production requirements. With years of experience in international trade, ANKO can assist you with the arrangement of Nalesniki making machines as required.In addition, ANKO’s sales engineers offer extensive consulting services, such as workflow optimization, staff deployment, and recipe. In the solution below, the machines can be adjusted in model and quantity according to real production needs. Want to get a quick quote and consultant? Please click the button below and fill out the form.

About Nalesniki Production Solution

ANKO SRP Automatic Pastry Sheet Machine or the SRP-CREPE Machines are capable of producing individual naleśniki sheets; the production starts by mixing naleśniki batter, then spreads and bakes it into a belt of naleśniki sheet, further automatically divides, counts and stacks the pancakes up into piles; the machine has the capacity of making the naleśniki sheet at an adjustable thickness range from 0.4-0.8 mm, and maximum width up to 220 mm/pc, however, special pancake sizes could be customized. Otherwise, ANKO BN- 24 Automatic Blini Production Line is comprised with the automatic pastry maker and production line is completed with the automatic filling, folding and rolling devices to produce savory or sweet naleśniki rolls. Three machines are recommended for producing ready-to-eat frozen naleśniki products for supermarkets, chain stores or food service brands.

Food's Gallery

- Texture and thickness of the wrappers can be customized

- Nalesniki are made evenly thin

- The browning of Nalesniki can be adjusted

- Production simulates manual wrapping techniques

- Nalesnik are sealed perfectly on both ends

1

Rolls / Wraps

- Sheeting / Wrapping

Case Studies

Semi-Automatic Blini Production Equipment Designed with Soft Pancake Stacker

Our agent gave a test run with ANKO's SRP for making blini, but failed to arrange them in a pile. Thus, ANKO's engineers developed…

Dumpling Equipment Designed to Enhance a Food's Handmade Look

Sometimes machine-made dumplings cannot meet client's required shape. Thus, ANKO designed handmade pleats…

Croquetas Automatic Production Line Design for an Indonesia Company

An ANKO client having had a successful food business in Colombia selling croquetas (croquette) to casinos and other retailers…

Dumpling Machine Helps to Increase Capacity and Standardize Products

Consumers really liked the handmade dumplings, but "sold out" was the most important issue with which the company had to deal…

Kibe Automatic Production Equipment Designed for a French Company

Kibe (Kibbeh) is one of the basic cuisines in the Middle East, so the high demand has made client's business booming. However, his employees couldn't meet…

Paneer Spring Roll Automatic Production Equipment Designed with Special Filling Device

Years ago, the client bought SR-24 spring roll machine from ANKO. This time, he placed another order because he trusts ANKO…

Danish Pastry Industrial Production Line for an Indian Company

The client supplies Danish pastries, chapatis, Mille-feuilles and cinnamon rolls, and they wished to upgrade their production capacity in order to increase the revenue…

The Best Selection - Get Started with Us to Discuss Your Needs

Blini Production Line

ANKO's Blini Production Line can automatically produce delicious blini. The stable depositor feeds equal portions of filling. Both weight and size of product are able to be controlled. With our production line, the texture of the products is unspoiled and competitive with handmade ones. We assure you of high quality and professional machines. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More Info Compare searies machineCompare with Similar Models

| Model no | Blini Production Line BN-24 | Automatic Spring Roll and Samosa Pastry Sheet Machine SRP Series |

|---|---|---|

| Description | Can be adjusted the product size and filling | High capacity and uniform products |

| Capacity | Max. 2,000 pcs/hr (based on pastry length of 240 mm) | 2,700 pcs/hr, 9 m/min (200 x 200 mm) |

| Weight | 75 - 80 g/pc | - |

| More Info | More Info |

Specifications

Capacity: 2000 pcs/hr

Features

- Voltage can be designated.

- The thickness of nalesniki wrapper and the amount of filling can be adjusted by parameter setting.

- The shape of nalesniki can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

- Downloads

- Best Selling

- Related Food Solutions Type