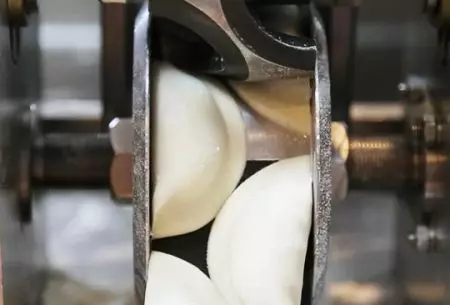

Automatic Meat Ball and Fish Ball Making Machine

Meat Ball And Fish Ball Maker

Model no : FMB-60

By putting paste materials such as meat paste or fish paste into the hopper, the FMB-60 can make ball-shaped foods automatically. It is equipped with a rotary round platform for putting a bowl of water to collect final products and prevent them from sticking. Want to get a quick quote and consultant? Please click the button below and fill out the form.

How It Works

Food's Gallery

- Al dente fish balls

- Meatballs are firm

- Fish, pork, and beef paste

- Meatballs look like handmade

- Meatballs are made with great uniformity

- Perfectly cooked meatballs

Specifications

- Dimensions: 500 (L) x 800 (W) x 1,400 (H) mm

- Power: 0.75 kW

- Capacity:20 mm dia.: 300 pcs/min25 mm dia.: 200 pcs/min35 mm dia.: 100 pcs/min

- Product dia.: 18–35mm (unadjustable)

- Including 3 extruding nozzles of standard sizes

- Weight (net): 150 kg

- Weight (gross): 250 kg

Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

- Producing fish balls, beef meat balls, pork meat balls and etc.

-

Process for making fish ballsRow fish -> Separate meat -> Remove fish bones -> Stir with sauces -> Form balls -> Boil -> Cool -> PackageFrozen fish meat -> Slice meat -> Mince -> Stir with sauces -> Form balls -> Boil -> Cool -> Package

-

Process for making beet meat balls, pork meat ballsFresh beef or pork meat -> Mince meat -> Stir with sources -> Form balls -> Boil -> Cool -> PackageFrozen beef or pork meat -> Slice meat -> Mince -> Stir with sauces -> Form balls -> Boil -> Cool -> Package

Case Studies

Multipurpose Filling and Forming Machine-Machinery Design for Indonesian Company

The client has two fishing vessels and two fish processing plants to process the six-ton daily catch. One plant is dedicated to…

Glutinous Rice Ball Machinery Designed to Solve Problem of Extruding Dry Filling

The client visited ANKO's booth at a Hong Kong exhibition for a solution to produce glutinous rice balls effectively…

Sweet Potato Ball Production Equipment Designed to Produce Small Sweet Potato Balls

The client owned a machinery which was not able to produce small sweet potato balls. They found that ANKO has…

Vegetarian Dumpling Machine for Taiwanese Company

Vegetarian foods are the client's primary products. The manual production no longer meets the growing demands, thus…

Stuffed Paratha Machine-Machinery Design for Indian Company

The client planned to expand into the U.S. market. He compared ANKO with other food machine suppliers and found ANKO is superior…

ANKO Japanese Manju Production Line - Machinery Design For a Japanese Company

This company owns a bakery, selling various buns and bread. Brown sugar is a common ingredient in Asian cooking…

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

In Taiwan, most traditional noodle machines have good productivity but are limited in the types of noodles…

- Downloads

- Best Selling