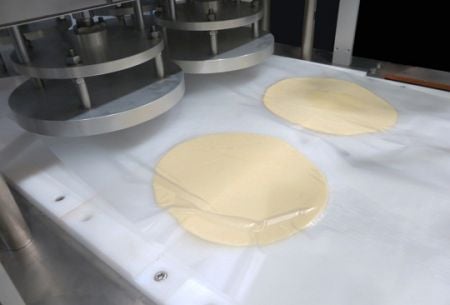

Automatic Filming and Pressing Machine

Automatic Filming And Pressing Machine

Model no : PP-2 Series

The PP-2 Series is designed to press dough balls into a circle and cover them with plastic films and moreover, stack the final products in a pile. It can make scallion pancake, paratha, pizza base, and stuffed paratha. Want to get a quick quote and consultant? Please click the button below and fill out the form.

How It Works

Food's Gallery

- Scallion pancake

- Lachha Paratha

- Thick Flatbread

- Thick Flatbread

Specifications

- Dimensions: 4,169 (L) x 920 (W) x 1,358 (H) mm

- Power: 0.09 kW

- Capacity: 1,500–3,200 pcs/hr

- Product dia.: 220 mm Air consumption: 400 L/min (@ 6 kg/cm^2)

- Weight (net): 585 kg

- Weight (gross): 805 kg

- Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

- The thickness and size of product can be adjusted as required.

- The number of final products in a pile can be adjusted.

Case Studies

Automatic Layer Paratha Production Line - Machinery Design for an Indian Company

The client contacted ANKO for food processing equipment solutions due to increasing demands. A total solution of Paratha…

Paratha Automatic Filming and Pressing Machine for a United Arab Emirates Company

The client required a machine to produce large paratha products. Thus, ANKO not only increased the size of pressing plates, but also…

Green Scallion Pie Production Line Design for a Taiwanese Company

The client would like to save labor cost and increase productivity. He found ANKO to seek the best solution for keeping handmade taste....

Automatic Layered Paratha Production Line for a Bangladeshi Company

The client decided to run a paratha production line due to the popularity of paratha. He trusted ANKO with Turnkey Planning Consulting Services…

Stuffed Paratha Machine-Machinery Design for Indian Company

The client planned to expand into the U.S. market. He compared ANKO with other food machine suppliers and found ANKO is superior…

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

- Downloads

- Best Selling