Flatbread

Flatbread Machine and Production Solutions

Model no : SOL-FLB-0-1

The Global Flatbread market is expected to reach $62.8 billion by 2026, with a compound annual growth rate of 6.2%. There are various types of popular Flatbreads including Chapati, Roti, Tortilla, Naan, Pita, and many more. If you are interested in receiving a quotation and personal assistance from our professional consultants, please feel free to send us your product specifications and other production requirements.

Flatbread Production Solutions

Recently, consumers are more health conscious, and many people prefer Flatbreads that are Vegan, Fat-free, Dairy-free, or Gluten-free. They are also drawn to products that are fast and convenient, hence various frozen and ready-to-eat Flatbreads have become a popular meal option. There are a wide variety of Flatbreads on the market today, including leavened and unleavened kinds, as well as plain, soft, multilayered, or ones made with puff pastry. The automated production process for different types of Flatbreads varies significantly.

ANKO’s team has extensive experience in ethnic food production and can provide customized Flatbread production solutions based on the client’s factory status, human resources, finances, estimated market size, and future development plans. We offer implemented solutions which include professional production line planning, workflow design recommendations, machine trial testing and recipe consultation services.

Food's Gallery

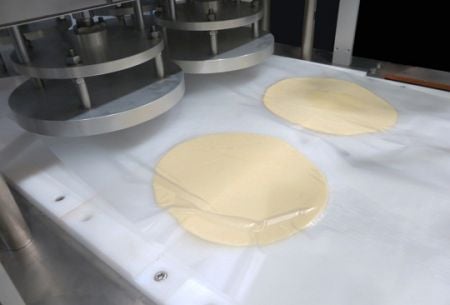

- Flatbreads are automatically heat pressed

- Flatbreads produced in large quantities

1

Extended Application

- Pressing

Case Studies

Stuffed Paratha Machine-Machinery Design for Indian Company

The client planned to expand into the U.S. market. He compared ANKO with other food machine suppliers and found ANKO is superior…

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

Automatic Layer Paratha Production Line - Machinery Design for an Indian Company

The client contacted ANKO for food processing equipment solutions due to increasing demands. A total solution of Paratha…

Paratha Automatic Filming and Pressing Machine for a United Arab Emirates Company

The client required a machine to produce large paratha products. Thus, ANKO not only increased the size of pressing plates, but also…

Green Scallion Pie Production Line Design for a Taiwanese Company

The client would like to save labor cost and increase productivity. He found ANKO to seek the best solution for keeping handmade taste....

Automatic Layered Paratha Production Line for a Bangladeshi Company

The client decided to run a paratha production line due to the popularity of paratha. He trusted ANKO with Turnkey Planning Consulting Services…

Kibbi Mosul Pastry Production Line Design for a Jordanian Company

Many Middle Eastern immigrants in western countries cannot forget the taste of hometown. Therefore, ANKO designed Kibbi Mosul Pastry Production Line…

The Best Selection - Get Started with Us to Discuss Your Needs

Pressing and Heating Machine

The APB Series is designed to press dough balls into a circle with a heating plate. It can make Peking duck wrapper, pita bread, filled paratha, chapati, and tortilla. According to individual needs, temperature, pressing time, and product thickness are adjustable. The Pressing & Heating Machine is made of food grade materials, stainless steel, and aluminum alloy (processed), and complies with hygiene regulations. We assure you of reliable and professional machines. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More InfoSpecifications

Capacity: 2,000 pcs/hr

Features

- Voltage can be designated.

- The thickness of flatbread wrapper and the amount of filling can be adjusted by parameter setting.

- The shape of flatbread can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

- Downloads

- Best Selling

- Related Food Solutions Type