X-Ray Inspection Machine

Food X-Ray Inspection Machine

Model no : XRI Series

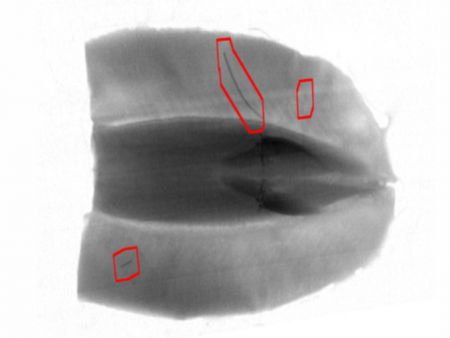

The ANKO Food Machine Company and the Nano Ray Solution Company have partnered to jointly create the innovative Food X-Ray inspection equipment. This device can be used in food production, pharmaceutical manufacturing, and chemical engineering factories to provide real-time detection of foreign objects and prevent production hazards. These include such items as rubber bands, plastics, machine parts, and bones during production, as well as finer contaminants such as metal threads, stainless steel dust, and plastic. This machine can also calculate the total output of products while identifying thus defects increasing your food production quality and safety.

ANKO’s Food X-Ray inspection device is built to comply with international safety regulations, is not radioactive, and is certified below 0.5 μSv/hr. After-sales services are provided by the original manufacturing companies ensuring maximum quality, efficiency, and safety standards. Want to get a quick quote and consultant? Please click the button below and fill out the form.

How It Works

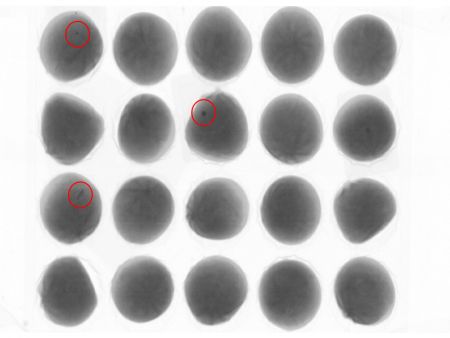

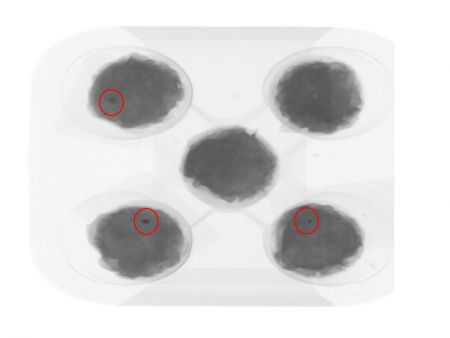

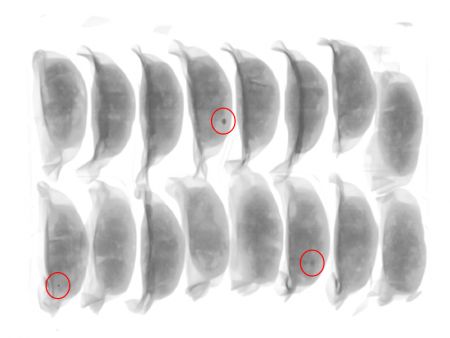

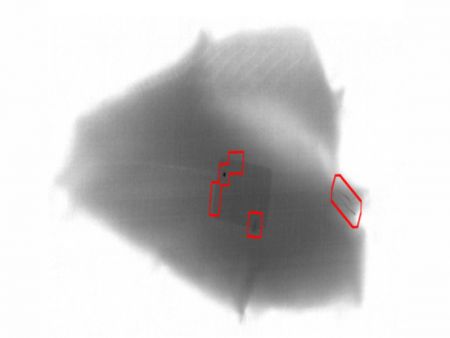

Food's Gallery

Specifications

| Model No. | XRI-200 | XRI-340 |

|---|---|---|

| Dimensions | 780 (L) x 1,940 (W) x 2,120 (H) mm | |

| Power | 1 kW | |

| Monitor | 21.5 inches | |

| X-ray source | 80 kV | |

| X-ray linear array detector | 300 mm | 500 mm |

| Conveyor width | 450 mm | |

| Highest detection size | 120 (W) x 100 (H) mm | 175 (W) x 120 (H) mm |

| Widest detection size | 200 (W) x 0 (H) mm | 340 (W) x 0 (H) mm |

| Highest sensitivity | SS #304 0.4 mm, Stone 1.0 mm, Bone 1.0 mm, Glass 2.0 mm | |

| Weight (net) | 220 kg | |

Features

-

Powerful

The ability to detect foreign objects as small as 0.4mm.

-

Wide Detection Range

The machine can see through objects and has a wider detection range than Automated Optical Inspection (AOI), Infrared, and Laser devices.

-

Versatile

It can detect a wide range of foreign objects (materials with minimum size) such as metal threads, SS #304 0.4 mm, stone 1.0 mm, Bone 1.0 mm, Glass 2.0 mm (For more information, please contact ANKO’s technicians directly.)

-

High Resolution

Advanced image precision ensures food inspection accuracy.

-

High Luminescence Efficiency

Improved luminous effect for clearer images and higher detection rates.

-

Safe to Use

The entire machine is covered by lead sheets and anti-radiation materials to prevent radiation leakage. All the safety measures exceed international standards.

-

Easy to Operate

A 21.5-inch monitor is installed with Artificial Intelligence (AI) image detection technology combined with Graphical User Interface (GUI) and intuitive adjustable parameter settings make this machine easy to use.

-

Simple Data Management

Data can easily be exported into reports, electronically saved, accessed, transmitted via USB, or sent to the internet for internal use for sharing with multiple locations.

-

Food Safety Designs

Food-grade rubber belts and anti-radiation rubber are used to for protection. Other shielding systems can be customized with special requests.

Case Studies

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

Ready-to-eat Tapioca Pearl Recipe Development for a Taiwanese Company

This Taiwanese client had no experience in tapioca pearl production and was referred by the OEM company to consult with ANKO…

Dumpling Equipment Designed to Enhance a Food's Handmade Look

Sometimes machine-made dumplings cannot meet client's required shape. Thus, ANKO designed handmade pleats…

Kibe Automatic Production Equipment Designed for a French Company

Kibe (Kibbeh) is one of the basic cuisines in the Middle East, so the high demand has made client's business booming. However, his employees couldn't meet…

Automatic Samosa Pastry Sheet Machine - Machinery Design for Kuwait Company

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one…

Multipurpose Filling & Forming Machine - Machinery Design for a Tunisian Company

The client is an owner of a hotel chain in Tunisia. Speaking of cooking, their insistence on food has gained favor with visitors…

Semi-Automatic Vegetarian Spring Roll Production Line - Machinery Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

Ready-to-eat Tapioca Pearl Recipe Development for a Taiwanese Company

This Taiwanese client had no experience in tapioca pearl production and was referred by the OEM company to consult with ANKO…

Dumpling Equipment Designed to Enhance a Food's Handmade Look

Sometimes machine-made dumplings cannot meet client's required shape. Thus, ANKO designed handmade pleats…

Kibe Automatic Production Equipment Designed for a French Company

Kibe (Kibbeh) is one of the basic cuisines in the Middle East, so the high demand has made client's business booming. However, his employees couldn't meet…

Automatic Samosa Pastry Sheet Machine - Machinery Design for Kuwait Company

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one…

Multipurpose Filling & Forming Machine - Machinery Design for a Tunisian Company

The client is an owner of a hotel chain in Tunisia. Speaking of cooking, their insistence on food has gained favor with visitors…

Semi-Automatic Vegetarian Spring Roll Production Line - Machinery Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

- DownloadsBest Selling