2017 Taipei Int’l Food Processing & Pharm. Machinery Show

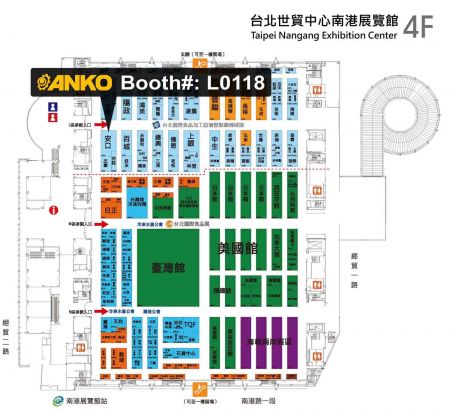

23 Jun, 2024Booth: 4F, L0118

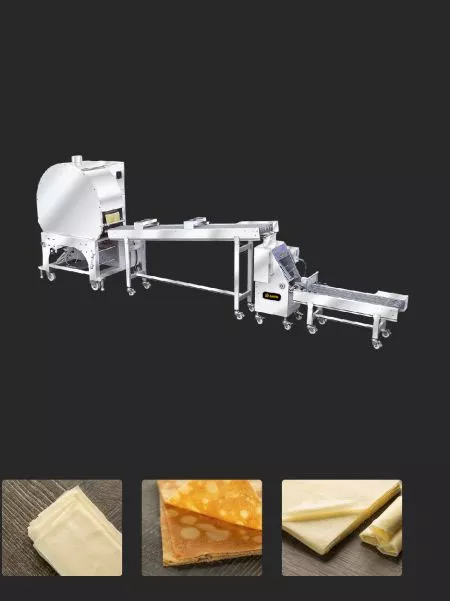

With globalization, the borders between countries become vague over time, which is then accompanied by fusion cuisines and creative recipes. ANKO are able to produce 265 types of food, including traditional ethnic foods and innovative food products. Moreover, machine customization is our greatest strength to meet individual demand. Not only are many kinds of machines and catalogues prepared, but we are ready to introduce and demonstrate machinery for you at 2017 Taipei Int'l Food Processing & Pharm. Machinery Show.

In addition to food processing machines, ANKO offers turnkey projects to integrate food preparation and product packaging equipment into a production line, which greatly saves purchaser's time and cost. If you plan to visit our booth, please click RESERVATION icon to fill in the following form.

See Us at the Show

- Date:9:00 am - 5:00 pm, 21-24 June, 2017

- Booth:4F, L0118

- Location:Taipei Nangang Exhibition Center. No.1, Jingmao 2nd Rd., Nangang District, Taipei City 11568, Taiwan (R.O.C.)