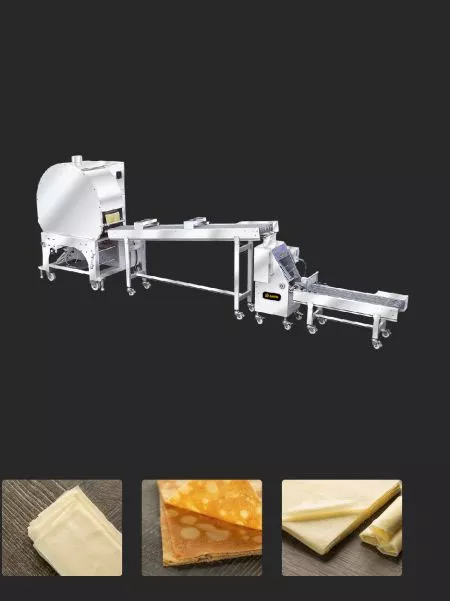

Automatic Spring Roll and Samosa Pastry Sheet Machine

Spring Roll Pastry And Samosa Pastry Maker

Model no : SRP Series

SRP Automatic Spring Roll and Samosa Pastry Sheet Machine is a food processing machine for automatically producing spring roll wrapper, samosa pastry, egg roll pastry, and even crepe. Simply prepare batter and the SRP Series will automatically finish the rest of steps, including baking, cutting, counting, and stacking. Finally, the baked pastries are nicely stacked in piles, ready to be packed, frozen, and sold at any time. It is also a samosa pastry machine. Samosa pastries can be made with the same process except that the way of cutting is different. Cutter can be customized as required. Want to get a quick quote and consultant? Please click the button below and fill out the form.

How It Works

Specifications

- Dimension: 5,500 (L) x 1,300 (W) x 1,900 (H) mm

- Power: 45A (35 kW), 45B (38 kW)

- Capacity (pastry of 200 x 200 mm): 2,700 pcs/hr, 9 m/min

- Thickness of pastry sheet: 0.4–0.8 mm

- Including 2.5 m cooling conveyor, rotary cutter and counting device, and stacking conveyor

- Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

-

Unique and Reliable DesignMicro-computer temperature controller can maintain a set temperature within ±1°C.The baking drum is covered by a safety guard to keep from being injured by the heat.Simply feed the well-mixed batter into hopper, machine will spray and bake batter, then cool, cut, count and stack pastry sheets automatically.

-

Process of Pastry Sheet ProductionMIXING -> FEEDING -> BAKING -> CUTTING -> COUNTING -> STACKING

- High capacity and uniform products

Case Studies

Machinery Design for a South African Company

The client's businesses, establishing in South Africa, extend from producing frozen food, baking products to central kitchen and catering service.…

Machinery Design for a Thai Company

The client has production lines for bakery and ethnic food, including baozi, siomay, hargao, bread, etc. In order…

Automatic Samosa Pastry Sheet Machine– Machinery Design for Kuwait Company

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one…

Shrimp Spring Roll Pastry Machinery Design for an American Company

As for spring roll pastry import, high cost and quality degradation caused by rising temperature during shipping prompted the client to purchase a machine…

For an Indian Machinery Design

The client is strict to control quality to ensure that consumers enjoy food with good quality and receive the best service. …

Machinery Design for a Spanish company

The company is well-known in Europe, mainly selling Chinese food. They always take client's health as priority…

Automatic Samosa Pastry Sheet Machine - Machinery Design for Indian Company

In order to meet the demand of samosa, the supplier was looking for a food processing machine manufacturer providing high-quality…

- Downloads

- Best Selling

FAQ

An Automatic Spring Roll and Samosa Pastry Sheet Machine is a valuable investment for food factories, restaurants, and frozen food manufacturers. The ANKO SRP Series produces up to 2,700 spring roll pastry sheets per hour, significantly reducing labor costs, increasing output, and maintaining consistent quality—far more efficient than manual production. Many ANKO clients have expanded from small shops or food carts into major restaurant chains, demonstrating that ANKO equipment delivers long-term production benefits, higher efficiency, and competitive growth in spring roll sheet production.

Yes. Purchasing food machinery includes full service before and after installation. We provide machine testing, product trial runs, and consultation through local offices and distributors worldwide, including the US, Europe, and Asia. After purchase, buyers receive installation, operator training, and after-sales service to ensure stable production. In addition, modular and partially customized options allow manufacturers to adjust machine settings to create different product textures, shapes, and flavors efficiently.

The price of a Automatic Spring Roll and Samosa Pastry Sheet Machine depends on the level of automation and customization required. The production line can be paired with mixers and other downstream equipment, allowing frozen food manufacturers and restaurant chains to purchase a complete one-stop solution. In addition to supplying machinery, ANKO also provides pre-sales consultation, operator training, and after-sales support to ensure fair pricing and reliable production performance throughout the entire process.