Peda

Your Peda Production Planning And Peda Recipe Consultant.

Model no : SOL-PDA-0-1

The Peda production solution that ANKO launched provides one-stop production planning based on your factory layout and production requirements. With years of experience in international trade, ANKO can assist you with the arrangement of Peda making machines as required.In addition, ANKO’s sales engineers offer extensive consulting services, such as workflow optimization, staff deployment, and recipe. In the solution below, the machines can be adjusted in model and quantity according to real production needs. Want to get a quick quote and consultant? Please click the button below and fill out the form.

About Peda Production Solution

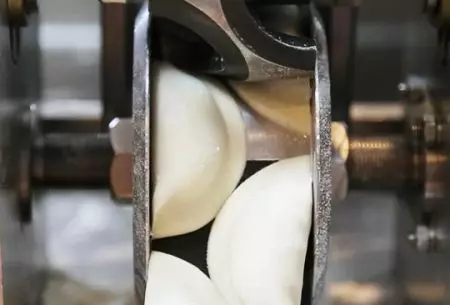

ANKO SD-97 Series Automatic Encrusting and Forming Machines are recommended for producing peda. These machines are designed to process various types of dough, in terms of different ingredient bases, moisture content and viscosity; and are capable of producing both plain and stuffed peda. There are patterned molds and/or generic shutters that can be applied to the machines, to form uniformed products into customized shapes; the sizes can be adjusted from 15 g up to 200 g per piece. SD-97SS, SD-97W and SD-97L come in different sizes and specifications, suitable for different size production plants, factories or central kitchens. And ANKO RC-180 Automatic Rounding Conveyor is compact in size and capable of producing ball-shaped products, sizing from 10 mm-30 mm in diameter, 10 g-35 g in weight and up to 3,000-3,600 pcs/hr.

SD-97W has a built-in Internet of Things (IoT) system which is connected to the Big Data Analytics. It collects data from each production and be utilized with extended applications to manage production balances, warehousing and scheduling. This technology offers you full control over production by “monitoring the machine operational status, maintenance machine lifespan, and digital production management”. An alarm will inform you the exact part that needs inspection to reduce any possible risks.

1

Filling / Forming

- Forming

Forming

A good filling and forming machine is the key to high-quality products. ANKO's peda forming machine can quickly mass-produce peda products that are uniform in weight and quality and have delightful pleats. The machine is easy to use. Put prepared dough and filling into hoppers, set parameters, and start producing peda.

Case Studies

Table Type Automatic Encrusting And Filling Machine-Machinery Design for UK Company

In order to reduce labor cost, the client went to a machinery show and was impressed with ANKO's food machine…

Stuffed Paratha Machine-Machinery Design for Indian Company

The client planned to expand into the U.S. market. He compared ANKO with other food machine suppliers and found ANKO is superior…

Automatic Samosa Pastry Sheet Machine– Machinery Design for Kuwait Company

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one…

What Things to Consider When Setting up a New Lachha Paratha Production Line

In order to increase capacity and improve product quality, the idea of shifting manual to automatic production...

Sambousek Automatic Production Equipment Designed with a Customized Half-moon Rotary Mold

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products…

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

Automatic Vegetarian Dumpling Machine for a Taiwanese Company

Vegetarian foods are the client's primary products. The manual production no longer meets the growing demands, in order to boost productivity…

The Best Selection - Get Started with Us to Discuss Your Needs

Automatic Encrusting and Forming Machine

Automatic Encrusting And Forming Machine can make either patterned or non-patterned products with a simple change of shutters; it can make either two colors or solid color with a simply change of dough hoppers. Not only the products with red bean paste, meat stuffing, or sesame paste but also plain products are producible. In conclusion, SD-97W can make dozens of ethnic foods such as meat bun, steamed bun, maamoul, meat pie, pan fried stuffed bun, mochi, crystal dumpling. Their look and taste are able to compare with handmade ones. The IoT (Internet of Things) have been installed to ensure that the production can be overseen by managers in real time on a mobile device, and the data can be collected and processed through Big Data Analytics to support decision making. We have also installed a maintenance reminder program to ensure consistent productivity. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More Info Compare searies machineFrequently Operate with

Automatic Rounding Conveyor

The RC-180 is designed to roll food products into a ball. After putting food products on the conveyor, the machine can convey food products to the working area for rolling. It can work with Automatic Encrusting and Forming Machine series (SD-97W/SD-97SS/SD-97L) to roll the quantitatively-divided filled or non-filled food into a ball. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More InfoCompare with Similar Models

| Model no | Automatic Encrusting and Forming Machine SD-97W | Automatic Encrusting and Forming Machine SD-97L | Automatic Table-Type Encrusting and Forming Machine SD-97SS |

|---|---|---|---|

| Description | Two color wrapper is available | Max. product weight up to 200 grams | Most compact machine |

| Capacity | 1,000 - 4,000 pcs/hr | 2,400 - 4,800 pcs/hr | 600 - 3,600 pcs/hr |

| Weight | 10 - 70 g/pc | 40 - 200 g/pc | 10 - 60 g/pc |

| More Info | More Info | More Info |

Specifications

Capacity: 4,000 pcs/hr

Features

- The built-in IoT function integrates the automated production line, and you can access this through remote monitoring via ANKO’s IoT dashboard.

- Voltage can be designated.

- The thickness of peda and the amount of filling can be adjusted by parameter setting.

- The shape of peda can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

Suitable for

-

Central kitchena place where a large amount of food is prepared and cooked, where the dishes are served at mealtimes or processed into read-to-heat meals and where the operator should pay attention to food safety.

-

Food factorya building where machines are equipped to prepare ingredients and make, cook and package food. E.g. frozen food factory, ready meal factory.

-

Kitchen design and equipment suppliera person or organization that provides production process planning, commercial kitchen appliance, and food making machines.

-

Machine distributora person or organization that buys great food machines and sells them to local customers.

-

Entrepreneur who wants to invest in the food industrysomeone who starts a new food business and needs a comprehensive solution, including consulting service in equipment purchase and manufacturing know-how.

-

Cloud kitchena place where a large amount of food is prepared and cooked for takeout and delivery.

-

Restaurant/Cafeteriait refers to restaurants/cafeterias that need to switch manual to automatic production, in order to save time and labor and increase capacity.

-

Hotela place where food is cooked and served to more than a hundred of people at mealtime or processed dishes into ready-to-heat meals to sell.

-

Schoolit refers to school caterers who serve lunch to teachers, students, and staff or a central kitchen shared by several schools.

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- Downloads

- Best Selling

- Related Food Solutions Type