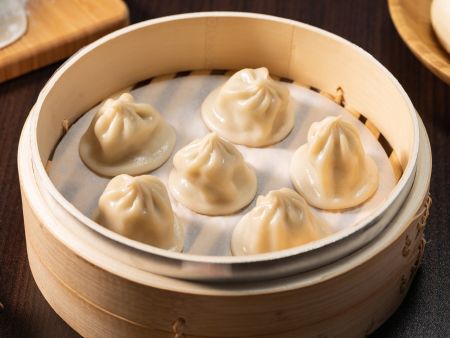

Automatic Mini Juicy Bun Production Line

Xiao Long Bao Machine And Production Solution (SOL-XLB-S-1)

Dozens Of Products With Various Filling And Shapes Can Be Made By The Most Flexible Filled Food Making Machine! The production line consists of HLT-700U Multipurpose Filling and Forming Machine and EA-100KA Forming Machine. The HLT-700U handles the thinness of wrappers and filling and the EA-100KA is used for shaping. The combination enables you to make soup dumpling, xiao long bao, and so on, and increase production capacity to 6,000 pieces per hour. Moreover, there are different types of shutter units that you can choose to make products with 9 or 12 pleats.

Food's Gallery

- Xiao Long Bao

- Soup Dumplings

- Xiao Long Bao-Fermented Dough

- Momo

- Khinkali

- Customization

Soup dumplings production solution's features

48-Liter Filling Hopper

Helps decrease refilling times and increase the overall efficiency of human resources.

A Commercial Automatic Mini Juicy Bun Machine Adopted By Top Food Makers

These well-known companies are attracted by the Mini Juicy Bun Machine’s high-efficiency features, including “easy-to-use”, “quick-to-clean”, and so on. There are only several steps to operate the Mini Juicy Bun Machine. Put mixed dough and filling into hoppers and start the machine paired with a custom-made shutter unit. Then, various foods can be automatically made. The shutter unit is easy to disassemble for cleaning to maintain good hygiene and the easy-to-use control panel enables you to save time on staff training.

The Favorite Brand Of International Top Food Makers. Seize Opportunities To Keep Pace With Top Companies.

The biggest concern when purchasing important equipment is unavailable service. At ANKO, our service goal is for all customers to receive our messages accurately and in a timely manner. Whether it's from ANKO’s official website, business and social platforms, you will be able to access detailed information on ANKO products and services. If you wish to further inquire about machine details or business advice, you can send messages or make calls directly through these platforms. ANKO will reply within 24 hours (excluding holidays) and provide you with the most appropriate solution in accordance to your product needs.

ANKO's Automatic Mini Juicy Bun Machine Features You Need To Know

- Different types of shutter unit: Can make products with 9 or 12 pleats.

- Can make up to 6,000 pc/hr, providing flexibility to your production plan.

- Simple structure, easy to disassemble: Parts are easy and quick to disassemble for cleaning.

- After-sales service: Reply within 24 hours after receiving your request to minimize losses from the shutdown.

- Easy-to-use control panel: user-friendly interface and machine design saves time on staff training.

Compare models

| Model no | Multipurpose Filling and Forming Machine HLT-700U | Multipurpose Filling and Forming Machine HLT-700XL | Double-Line Multipurpose Filling and Forming Machine HLT-700DL |

|---|---|---|---|

| Description | Tasty Appearance as handmade look | A wide range of standard rotary molds are available | Highest production capacity |

| Capacity | 2,000 - 12,000 pcs/hr | 2,000 - 10,000 pcs/hr | 4,000 - 20,000 pcs/hr |

| Weight | 13 - 100 g/pc | 13 - 100 g/pc | 13 - 100 g/pc |

| More Info | More Info | More Info |

Why Should You Choose ANKO's Spring Roll Machine?

Praised By Over 114 countries. We Do Great Not Only Mini Juicy Bun, But Also Different Kinds Of Ethnic Food.

- Help you upgrade your business with our 47 years' experience in food equipment.

- What you buy is not just a machine but a recipe consulting service provided by our food researcher to ensure the food is delicious.

- Provide a friendly turnkey project including vegetable cutting machine, mixer and steamer on the front- and back-end.

With over 47 years of experience in the food machinery industry, ANKO is familiar with the market and industry conditions. ANKO can help you make decisions and provide recommendations for industrial upgrades thanks to our decades of accumulated market information and food development. We are dedicated to providing customers with the latest and most valuable information.

ANKO's machines are now used in manufacturing factories in 114 countries. Food made by ANKO's food machines is served in more than half of the world's countries. We have accumulated years of international experience and a wealth of international expertise. ANKO can assist in designing production lines according to customer needs, provide comprehensive whole plant solutions and equipment for plant planning, raw material processing, production line planning, production process optimization, as well as new product development and customization.

The ANKO factory has a machine demonstration area as well as a bright and clean high-standard food lab which provide a variety of flours, seasonings, fillings, additives and various food processing equipment such as mixers, vegetable cutters, hydro extractors, steamers, ovens and other relevant equipment. You can test all kinds of recipes and machines at any time to ensure that the ANKO equipment meets your actual needs and requirements.

↓ Get a quote within 24 hours↓

Need support?

Search for a topic or pick one below. We'll find you the best support options.