Puran Poli

Your Puran Poli Production Planning And Puran Poli Recipe Consultant.

Model no : SOL-PPL-0-1

The Puran Poli production solution that ANKO launched provides one-stop production planning based on your factory layout and production requirements. With years of experience in international trade, ANKO can assist you with the arrangement of Puran Poli making machines as required.In addition, ANKO’s sales engineers offer extensive consulting services, such as workflow optimization, staff deployment, and recipe. In the solution below, the machines can be adjusted in model and quantity according to real production needs. Want to get a quick quote and consultant? Please click the button below and fill out the form.

About Puran Poli Production Solution

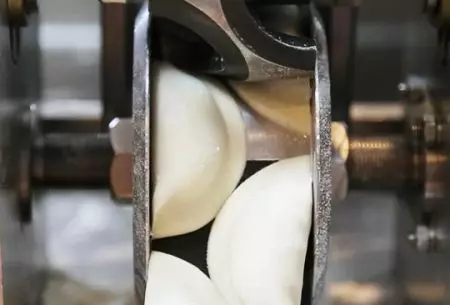

ANKO APB Pressing and Heating Machine is equipped with an instant heat-pressing function that is able to form uniformed flatbreads without overcooking the dough, suitable for manufacturing products like puran poli, roti or khakhra for chain restaurants, supermarkets or frozen food brands. The machine is recommended for producing various other plain or stuffed flat breads and ethnic pastries.

Food's Gallery

- Heat pressing time can be adjusted to meet the client’s product specifications

- Heating temperature can be adjusted to meet the client’s product specifications

- Puran Poli made with highly efficient automated production

- The thickness of the dough can be adjusted to meet the client’s product specifications

1

Extended Application

- Pressing

Case Studies

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

Automatic Layer Paratha Production Line - Machinery Design for an Indian Company

The client contacted ANKO for food processing equipment solutions due to increasing demands. A total solution of Paratha…

Automatic Samosa Pastry Sheet Machine– Machinery Design for Kuwait Company

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one…

Rasgulla Automatic Production Line Design for an Indian Company

Rasgulla is a classic Indian sweet which can be produced by SD-97 series and RC-180 Rounding Conveyor. In order to increase production capacity and save labor costs…

Automatic Vegetarian Dumpling Machine for a Taiwanese Company

Vegetarian foods are the client's primary products. The manual production no longer meets the growing demands, in order to boost productivity…

Automatic Samosa Pastry Sheet Machine - Machinery Design for Indian Company

The client runs a bakery group whose divisions are present in many countries of the Middle East and Asia. They form a complete…

Danish Pastry Industrial Production Line for an Indian Company

The client supplies Danish pastries, chapatis, Mille-feuilles and cinnamon rolls, and they wished to upgrade their production capacity in order to increase the revenue…

The Best Selection - Get Started with Us to Discuss Your Needs

Pressing and Heating Machine

The APB Series is designed to press dough balls into a circle with a heating plate. It can make Peking duck wrapper, pita bread, filled paratha, chapati, and tortilla. According to individual needs, temperature, pressing time, and product thickness are adjustable. The Pressing & Heating Machine is made of food grade materials, stainless steel, and aluminum alloy (processed), and complies with hygiene regulations. We assure you of reliable and professional machines. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More InfoSpecifications

Capacity: 2,000 pcs/hr

Features

- Voltage can be designated.

- The thickness of puran poli wrapper and the amount of filling can be adjusted by parameter setting.

- The shape of puran poli can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

- Downloads

- Best Selling

- Related Food Solutions Type