Automatic Shumai Machine

Triple Line Shumai Machine

Model no : HSM-900

ANKO’s automatic triple-line shumai machine can make 9,000 shumai per hour, suitable for food factories, co-packers, and chain restaurants to boost production capacity of frozen shumai and ready-to-eat shumai. The production processes start from wrapper making, filling, forming, decorating, and arranging. Its flexibility enables you to make unique and delicious shumai by adjusting wrapper thickness, filling weight, appearance, decoration, and colors, or extend product line, such as shrimp shumai and fish shumai. In addition, the shumai machine is designed with an innovative arranging function, allowing you to adjust the distance between shumai in a row and between lines, which helps workers pack final products efficiently, or when automatically arranging shumai on trays with an aligning machine, you could minimize the distances and have the most shumai on a tray. Want to get a quick quote and consultant? Please click the button below and fill out the form.

How It Works

Food's Gallery

- Shumai with different garnish

- Distance between shumai is adjustable

- Raw shumai

- Filling is densely packed

- Shumai is automatically garnished with peas

- Shumai is automictically garnished with fish roe

Optional Accessories

CE kit

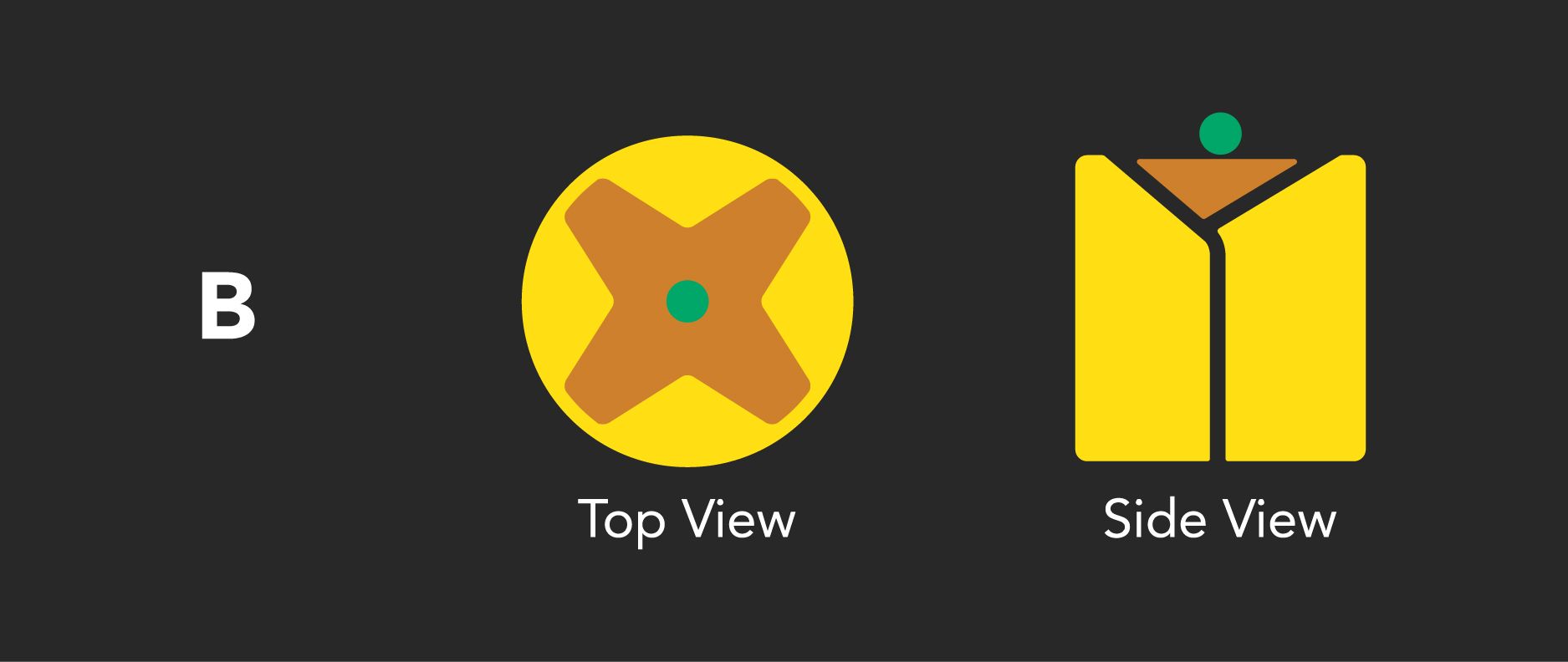

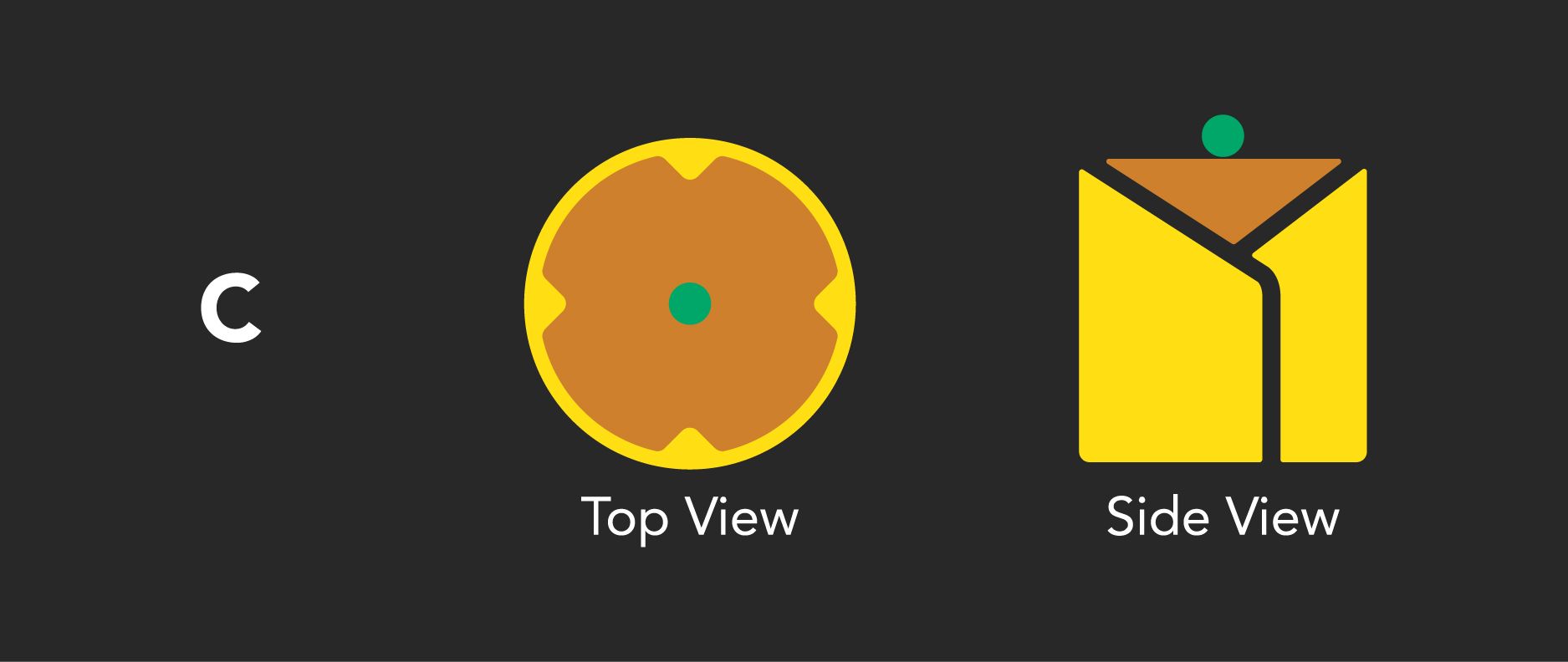

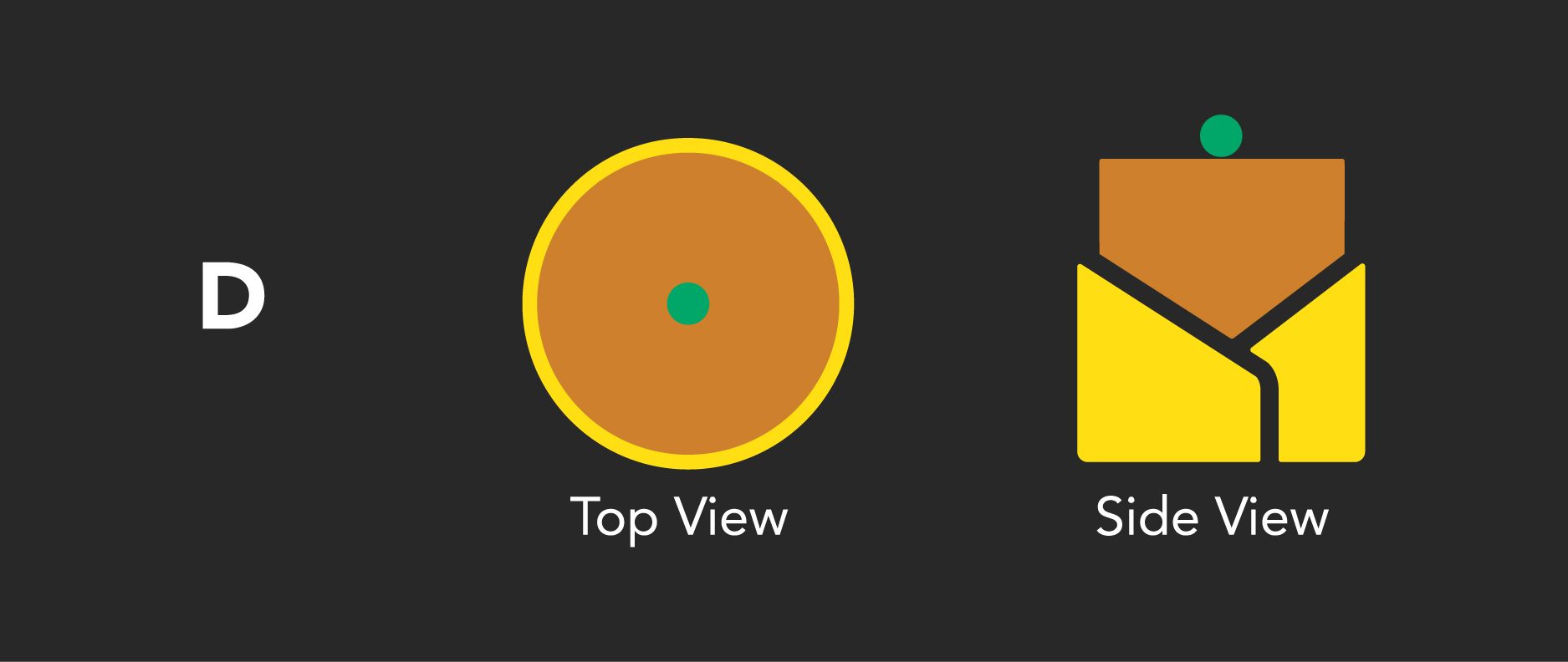

Food Dimension

| Diameter | 24 mm | 30 mm | 32 mm | 35 mm |

| Height | 25-35 mm | 25-35 mm | 25-35 mm | 25-35 mm |

| Weight | 14-17 g | 19-26 g | 21-29 g | 25-35 g |

| Thickness of Pastry | 0.3-0.5 mm | 0.3-0.5 mm | 0.3-0.5 mm | 0.3-0.5 mm |

| Size of Pastry 60x60 mm | B/D | B/D | C/D | C/D |

| Size of Pastry 65x65 mm | A/C | B/D | B/D | B/D |

| Size of Pastry 70x70 mm | A/B | A/C | A/C | B/D |

|

|

|

|

Specifications

- Type: Triple line

- Dimensions: 1,510 (L) x 1,270 (W) x 1,965 (H) mm

- Power: 3.3 kW

- Capacity: 9,000 pcs/hr

- Product name: Shumai

- Product dimension: 24–35 (Dia.) x 25–35 (H) mm

- Product weight: 14–35 g/pc

- Dough belt:Width: 60–70 mmThickness: 0.3–0.5 mm

Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

-

Increase production capacity and raise revenueCompared to the double-line shumai machine, the production capacity of the triple-line shumai machine increases by 50%, which means that your output could increase by 24,000 pieces to 72,000 pieces per day (8 hours).

-

Distance between shumai in a row and between lines are adjustableTo facilitate manual packaging and automatic tray arranging.

-

User-friendly design reduces operator fatigueWith the enhancement of the mechanism design, the shumai machine can run smoothly and quietly that not only gives a longer lifespan of machine, but also helps build a friendly working environment to reduce operator fatigue.

-

Easy to cleanAll parts in contact with food can be disassembled easily for washing.

-

Extended ApplicationCan connect with ALT-600 Aligning Machine to increase automation. (For further information on ALT-600 Aligning Machine, please contact us.)

- Suitable for a wide range of filling, such as fish paste and ground meats, or with vegetable dices, meat dices, shrimp dices, or other larger ingredients.

- The size and thickness of wrapper as well as the weight, diameter, and height of shumai can be customized.

- Equipped with a sensor to control filling system. To avoid food waste, the filling system extrudes filling only when the sensor detects wrapper.

- Equipped with a speed controller to control the wrapper conveying speed.

- The control panel is designed with icons, easy to operate.

- Garnishing set and granule feeding set are optional for decorating your shumai.

Case Studies

Automatic shumai machine designed to solve supply shortages of shumai

The client is a co-packer, who has been contracted by many food companies to produce Chinese food and dim sum. ...

Siomay Production Machine Designed to Solve Insufficient Production Capacity

Capacity In order to increase production capacity, the client switched from manual to automatic production and bought a semi-automatic siomay machine....

Machinery Design for Mauritian Company

The growing demand and labor costs prompted the client to find an automation solution. Through his friend's introduction, he knew that ANKO is a professional food machine manufacturer...

Machinery Design for an Indonesian Company

The expansion and increase of business were followed by a problem that their original siomay machine could not meet higher demands, so the client contcted ANKO...

Chinese Shumai Production Line Design for a Hong Kong Company

With increasing restaurant business, the owner of a dim sum restaurant would like to expand his production capacity with....

ANKO Automatic Shumai Machine – Machinery Design for Malaysian Company

With the new online shopping site, the client received more orders than before, so that they planned to purchase machine for....

Compare models

- Downloads

- Best Selling