Coxinha

Your Coxinha Production Planning And Coxinha Recipe Consultant.

Model no : SOL-CXH-S-1

The “coxinha production solution” that ANKO launched provides one-stop production planning based on your factory layout and production requirements. With years of experience in international trade, ANKO can assist you with the arrangement of coxinha making machines as required. In addition, ANKO’s sales engineers offer extensive consulting services, such as workflow optimization, staff deployment, and recipe. Want to get a quick quote and consultant? Please click the button below and fill out the form.

About Coxinha Production Solution

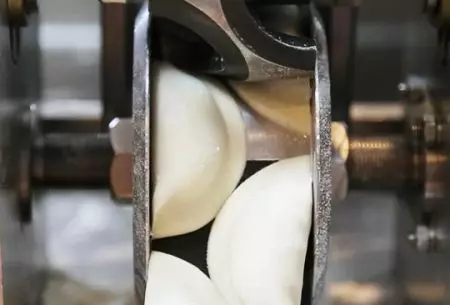

ANKO Automatic Encrusting and Forming Machine can help automate complicated manual processes, making attractive and delicious coxinha. Through setting parameters, putting dough and filling into the hoppers, and starting the machine, conxinha can be quickly manufactured. With the well-designed and stable forming system, every coxinha can be sealed and formed perfectly with consistent quality and a drop shape.

SD-97M has a built-in Internet of Things (IoT) system which is connected to the Big Data Analytics. It collects data from each production and be utilized with extended applications to manage production balances, warehousing and scheduling. This technology offers you full control over production by “monitoring the machine operational status, maintenance machine lifespan, and digital production management”. An alarm will inform you the exact part that needs inspection to reduce any possible risks.

Food's Gallery

- Using a special mold to form the tear-drop shaped Coxinha

- Coxinha made with automated production

- Preserves the original texture of the filling ingredients

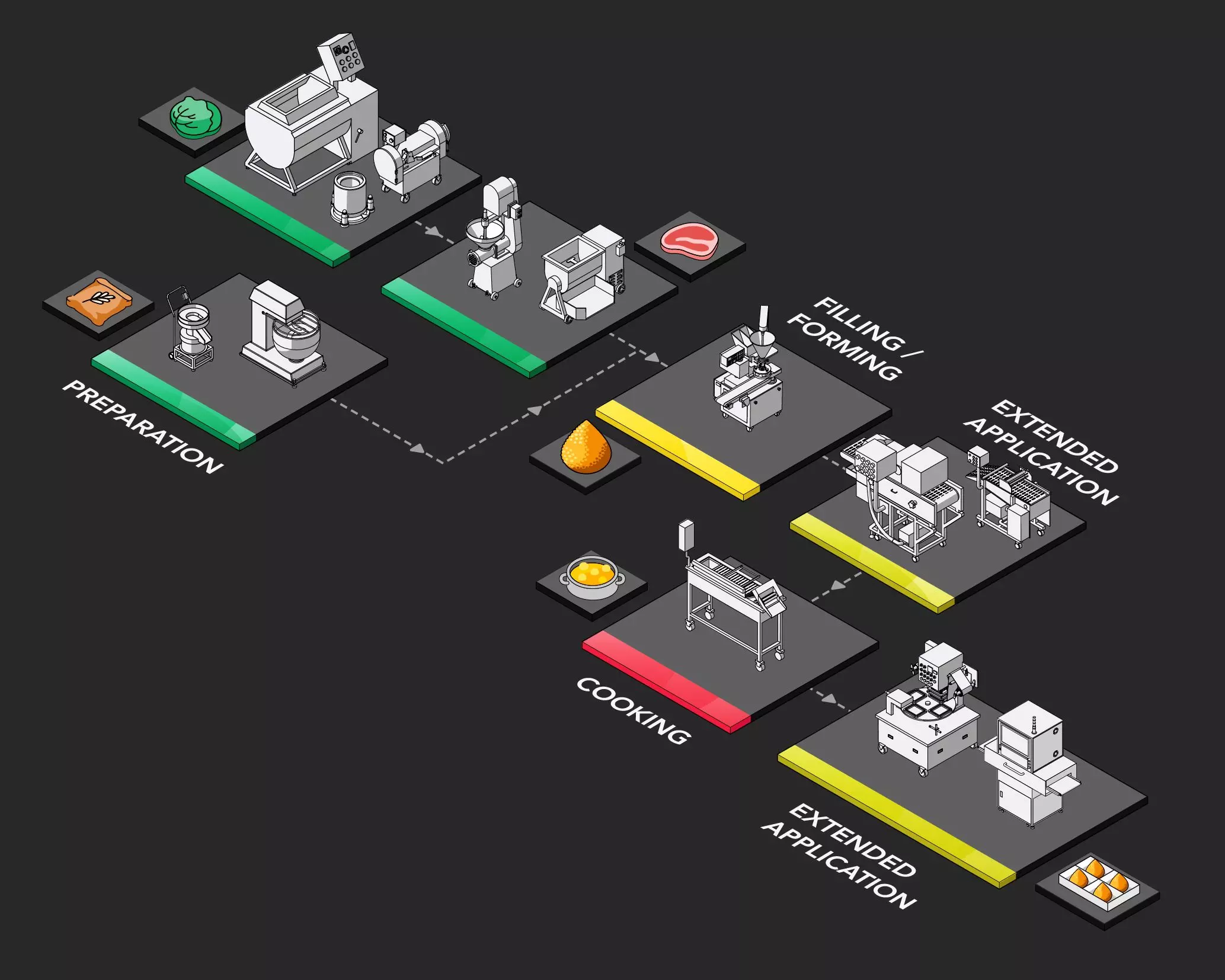

Turnkey and Production Planning

1

Preparation

- Sieving

- Mixing

- Vegetable Cleaning

- Vegetable Cutting

- Extracting

- Meat Mincing

- Seasoning

2

Filling / Forming

- Forming

3

Cooking

- Frying

Frying

Having a deep-fryer that suits your production capacity can quickly deep-fry batter-and-breadcrumb-coated coxinha. The deep-fryer combined in the production line is equipped with a digital controller and conveyor to evenly deep-fry both sides with constant temperature and automatically deliver products out of the oil tank to facilitate packaging.

4

Extended Application

- Batter Breading

- Crumb Breading

- Sealing

- Quality Control

Quality Control

ANKO’s X-Ray Inspection Machine can detect various metals, bones, glass, and other foreign objects during food production; even something as small as 0.4mm. The machine is equipped with luminating and buzzer warnings to ensure real-time contaminant detection, prevent artificial hazards, and increase overall product quality.

Case Studies

Stuffed Cassava Ball Machinery Design for a Peruvian Company

The client's stuffed cassava products had been made by hand. When the demand increased to a certain amount, he was seeking a machine…

Croquetas Automatic Production Line Design for an Indonesia Company

An ANKO client having had a successful food business in Colombia selling croquetas (croquette) to casinos and other retailers…

Semi-Automatic Burrito Forming Machine Designed for the U.S. company

The client has run the company offering Mexican food for over 25 years. They not only have privately-held restaurant chains, but also…

Stuffed Paratha Machine-Machinery Design for Indian Company

The client planned to expand into the U.S. market. He compared ANKO with other food machine suppliers and found ANKO is superior…

Pineapple Cake Automatic Production Line Set up for New Product Launch

The client found that Taiwanese pineapple cake is very popular and delicious, so he decided to produce pineapple cakes and sell…

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

The Noodle Extruder can be used to produce Spaghetti, Noodle and Noodles with Multi Structured, such as heart-shaped, fish-shaped, dumbbell-shaped, and…

Automatic Vegetarian Dumpling Machine for a Taiwanese Company

Vegetarian foods are the client's primary products. The manual production no longer meets the growing demands, in order to boost productivity…

The Best Selection - Get Started with Us to Discuss Your Needs

Automatic Encrusting and Forming Machine

The Automatic Encrusting and Forming Machine can make a variety of food, ranging from Chinese bao, meat pie, sticky rice ball, sesame ball, Brazilian coxinha to Indian classic dessert rasgulla, and even the traditional Middle Eastern food - kibbeh, which is filled with loose meat and shaped like a rugby, can be formed and is comparable with handmade kibbeh. The machine can work with different dough and filling. Moreover, you can have food with different shapes and delicate pleats, simply by changing shutter unit, or install double dough hopper to make two-color food. All plastic parts in contact with food are safe and non-toxic, meeting food safety regulations. The IoT (Internet of Things) have been installed to ensure that the production can be overseen by managers in real time on a mobile device, and the data can be collected and processed through Big Data Analytics to support decision making. We have also installed a maintenance reminder program to ensure consistent productivity. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More Info Compare searies machineCompare with Similar Models

| Model no | Automatic Encrusting and Forming Machine SD-97M | Automatic Table-Type Encrusting and Forming Machine SD-97SS | Automatic Encrusting and Forming Machine SD-97L |

|---|---|---|---|

| Description | Making tasty appearance with shape of rugby | Most compact machine | Max. product weight up to 200 grams |

| Capacity | 1,000 - 4,000 pcs/hr | 600 - 3,600 pcs/hr | 2,400 - 4,800 pcs/hr |

| Weight | 10 - 70 g/pc | 10 - 60 g/pc | 40 - 200 g/pc |

| More Info | More Info | More Info |

Specifications

Capacity:120 kg/hr or 3,000 pc/hr

*Based on 40-gram coxinha

Features

- The built-in IoT function integrates the automated production line, and you can access this through remote monitoring via ANKO’s IoT dashboard.

- Voltage can be designated.

- Vegetable cutter can julienne, slice, dice vegetables.

- The thickness of wrapper and the amount of filling can be adjusted by parameter setting.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

Suitable for

-

Central kitchena place where a large amount of food is prepared and cooked, where the dishes are served at mealtimes or processed into read-to-heat meals and where the operator should pay attention to food safety.

-

Food factorya building where machines are equipped to prepare ingredients and make, cook and package food. E.g. frozen food factory, ready meal factory.

-

Kitchen design and equipment suppliera person or organization that provides production process planning, commercial kitchen appliance, and food making machines.

-

Machine distributora person or organization that buys great food machines and sells them to local customers.

-

Entrepreneur who wants to invest in the food industrysomeone who starts a new food business and needs a comprehensive solution, including consulting service in equipment purchase and manufacturing know-how.

-

Cloud kitchena place where a large amount of food is prepared and cooked for takeout and delivery.

-

Restaurant/Cafeteriait refers to restaurants/cafeterias that need to switch manual to automatic production, in order to save time and labor and increase capacity.

-

Hotela place where food is cooked and served to more than a hundred of people at mealtime or processed dishes into ready-to-heat meals to sell.

-

Schoolit refers to school caterers who serve lunch to teachers, students, and staff or a central kitchen shared by several schools.

What services and benefits are covered in the solution?

Want to expand coxinha business? Let ANKO, a food machinery expert, do you a favor

Unfamiliar with coxinha production line? No experience in production planning? Worried consulting coxinha machine suppliers waste too much time or there is no training and reliable after-sales service? You can rest assured that ANKO, 45 years in the field, will handle your concerns. In order to resolve the difficulties that customers across the world have when purchasing, ANKO provides comprehensive "one-stop" service – front- and back-end equipment configuration, turnkey project planning, machine trial, and installation and training. ANKO's consultants have been praised by customers from 113 countries and are ready to assist you in improving performance and expanding unlimited business.

Coxinha equipment integration and effectiveness assessment are conducted by our professionals

With 45 years' experience in providing services for numerous food factories and central kitchens, ANKO is your professional turnkey project consultant in coxinha production. Based on your factory size and manpower, we can provide custom-made suggestions of coxinha equipment configuration and integration, wiring, production plan, and other details. In addition, ANKO assists you in thoroughly assessing the effectiveness of a solution and estimating manpower and time that could be reduced, which allows you to focus on operation and market development.

One-stop coxinha machine repair service offers you consistent service quality

Having different coxinha making machines in your factory, you might need to contact different suppliers to get them repaired. ANKO assured you that all machines from ANKO would be handled properly. As long as the machine is bought from ANKO, no matter it is a vegetable cutter, mixer, coxinha forming machine, or packing machine, you do not have to contact different people, all you need is to make a call to ANKO.

45 years' experience in selling coxinha machines all over the world, providing high-quality food recipe and adjustment suggestions

How can the machine-made coxinhas be as delicious as the handmade ones? ANKO has a professional team and food researchers to offer customers the best recipes and adjustment suggestions. Currently, we have sold our products to more than 100 countries. ANKO's food machines can make a wide variety of food, including Chinese, Indian, the Middle Eastern, Latin American, European, and other ethnic food. With a wealth of experience, ANKO is confident of making the most suitable suggestions for your coxinha recipe and helps you be unbeatable in the market.

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- Best Selling

- Related Food Solutions Type