Paratha

Your Paratha Production Planning And Paratha Recipe Consultant.

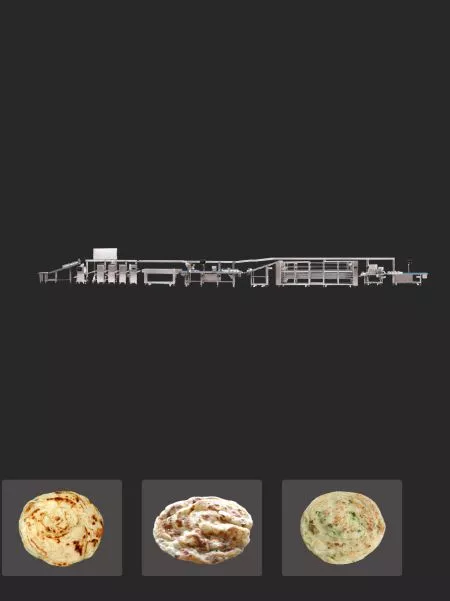

Model no : SOL-PTA-0-1

The aging workforce is becoming a global issue, which results in reduced labor supply; hence, various industries are shifting their productions from manual to automated. ANKO is the leading brand in the Food Machinery Industry, and has over 45 years of trade experience. ANKO’s Paratha Machine is fully automatic, and the settings could be adjusted to produce paratha with different oil content and layering. ANKO has professional recipe and formula research and developers, who are competent in ethnic and international cuisines, and are capable of helping clients customize exquisite food products. Want to get a quick quote and consultant? Please click the button below and fill out the form.

Paratha Production Solutions Tailored to Meet Your Needs

ANKO Paratha Machine has the capacity of 3000pc/hr., and the production line is fully automatic. The process starts from rolling the dough flat into sheets, and then drizzles oil onto the dough sheets, then to be rolled, pressed and formed into individual products. In addition to the Paratha Machine, we can also provide clients with dough mixer, automatic filming and pressing machine to implement the assembly lines. Our goal is to be efficient, and serve as your one stop solution.

Food's Gallery

- The browning of Paratha can be adjusted

- Paratha looks and tastes like handmade

1

Rolls / Wraps

- Sheeting / Wrapping

Sheeting / Wrapping

ANKO’s Paratha Machine can be set to produce products from 40g to 130g, and the unique rolling device is capable of creating up to 32 layers in one paratha; we have also developed recipes that can produce paratha with 12 to 18 layers, that are so flaky and taste similar to the classic handmade paratha. Moreover, we can also help customize your production line by installing a filling device, in order to make stuffed parathas.

Case Studies

Ultra High Capacity Paratha Production for a Bangladeshi client

The client required a daily production capacity of at least 100,000 Parathas, and ANKO customized a Triple Line Production Solution to meet their needs…

A New Lachha Paratha Production Line Set-up for an Indian Company

In order to increase capacity and improve product quality, the idea of shifting manual to automatic production has been lingering in client's mind...

Automatic Layered Paratha Production Line for a Bangladeshi Company

The client decided to run a paratha production line due to the popularity of paratha. He trusted ANKO with Turnkey Planning Consulting Services…

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

Stuffed Paratha Machine-Machinery Design for Indian Company

The client planned to expand into the U.S. market. He compared ANKO with other food machine suppliers and found ANKO is superior…

Danish Pastry Industrial Production Line for an Indian Company

The client supplies Danish pastries, chapatis, Mille-feuilles and cinnamon rolls, and they wished to upgrade their production capacity in order to increase the revenue…

Automatic Layer Paratha Production Line - Machinery Design for an Indian Company

The client contacted ANKO for food processing equipment solutions due to increasing demands. A total solution of Paratha…

The Best Selection - Get Started with Us to Discuss Your Needs

Automatic Layer & Stuffed Paratha Production Line

LP-3001 is fully automatic to produce similar products such as paratha, pie and the like. Placing well-mixed dough and margarine into hoppers is the only thing to do. Then the fully automatic production processes include dough pressing, margarine extruding, the first folding and sheeting, the second folding and sheeting, rolling, cutting into balls, and pressing to form tasty products. When the production line equips a filling machine, LP-3001 can form various tastes of stuffed pastries, such as curry pastries, barbecued pork pastries, bean paste pastries, etc. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More Info Compare searies machineCompare with Similar Models

| Model no | Automatic Layer & Stuffed Paratha Production Line LP-3001 | Lacha Paratha and Green Scallion Pie Production Line LAP-5000 |

|---|---|---|

| Description | Special structure can make dough balls with up to 32 layers | More efficient dough feeder |

| Capacity | 3,000 pcs/hr | 2,100 - 6,300 pcs/hr |

| Weight | 40 - 130 g/pc | 50 - 130 g/pc |

| More Info | More Info |

Specifications

Capacity: 3,000 pcs/hr or 300 kg/hr

Features

- Voltage can be designated.

- The thickness of paratha wrapper and the amount of filling can be adjusted by parameter setting.

- The shape of paratha can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

Suitable for

-

Central kitchena place where a large amount of food is prepared and cooked, where the dishes are served at mealtimes or processed into read-to-heat meals and where the operator should pay attention to food safety.

-

Food factorya building where machines are equipped to prepare ingredients and make, cook and package food. E.g. frozen food factory, ready meal factory.

-

Kitchen design and equipment suppliera person or organization that provides production process planning, commercial kitchen appliance, and food making machines.

-

Machine distributora person or organization that buys great food machines and sells them to local customers.

-

Entrepreneur who wants to invest in the food industrysomeone who starts a new food business and needs a comprehensive solution, including consulting service in equipment purchase and manufacturing know-how.

-

Cloud kitchena place where a large amount of food is prepared and cooked for takeout and delivery.

-

Restaurant/Cafeteriait refers to restaurants/cafeterias that need to switch manual to automatic production, in order to save time and labor and increase capacity.

-

Hotela place where food is cooked and served to more than a hundred of people at mealtime or processed dishes into ready-to-heat meals to sell.

-

Schoolit refers to school caterers who serve lunch to teachers, students, and staff or a central kitchen shared by several schools.

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- Downloads

- Best Selling

- Related Food Solutions Type