Lachha Paratha

Your Lachha Paratha Production Planning And Lachha Paratha Recipe Consultant.

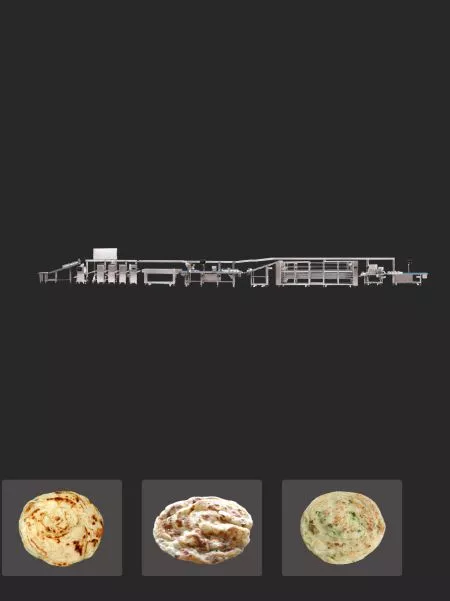

Model no : SOL-LPT-0-1

ANKO’s Lachha Paratha production solution provides comprehensive consulting service and solves problems of production based on our years of experience, which enables you to automate production with less effort and stress. You can have one-stop shopping for not only Lachha Paratha making machines, such as sieving, wrapper making, and packaging, but also your own proposal that is made by ANKO's sales engineers according to your production needs, factory layouts, existing equipment, human resources, etc. In the solution below, the machines can be adjusted in model and quantity according to real production needs. Want to get a quick quote and consultant? Please click the button below and fill out the form.

About Lachha Paratha Production Solution

ANKO LAP-5000 Lachha Paratha Machine is professionally designed to produce lacha parathas; by adding the dough in the dough tank, the machine automatically folds in oil into the dough, and the patterned pulling and folding device is able to form multiple layers, which can produce final products that taste similar to handmade lachha paratha. And by attaching ANKO PP-2 Automatic Filming and Pressing Machine, can form a continuous product line, suitable for mass production in large manufacturing facilities.

Food's Gallery

- Great quality Lachha Paratha made with highly efficient automated machinery

- Chopped Scallions are evenly distributed on the Lachha Paratha

- The unique pastry folding device is designed to produce Lachha Paratha with 32 layers that are flaky and light

- Flaky and multilayered Lachha Paratha

- Lachha Paratha are uniformly made with highly efficient automated machinery

1

Rolls / Wraps

- Sheeting / Wrapping

Case Studies

A New Lachha Paratha Production Line Set-up for an Indian Company

In order to increase capacity and improve product quality, the idea of shifting manual to automatic production has been lingering in client's mind...

ANKO Lachha Paratha Production Line to Reduce Labor Cost and Increase Productivity

The client is a frozen food manufacturer, producing Indian food and selling to grocery stores and supermarkets...

Automatic Layered Paratha Production Line for a Bangladeshi Company

The client decided to run a paratha production line due to the popularity of paratha. He trusted ANKO with Turnkey Planning Consulting Services…

Automatic Samosa Pastry Sheet Machinery Design for a Kuwait Company

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one…

Multipurpose Filling & Forming Machine - Machinery Design for a Tunisian Company

The client is an owner of a hotel chain in Tunisia. Speaking of cooking, their insistence on food has gained favor with visitors…

Rasgulla Automatic Production Line Design for an Indian Company

Rasgulla is a classic Indian sweet which can be produced by SD-97 series and RC-180 Rounding Conveyor. In order to increase production capacity and save labor costs…

Glutinous Rice Ball Machinery Designed to Solve Problem of Extruding Dry Filling

The client visited ANKO's booth at a Hong Kong exhibition for a solution to produce glutinous rice balls effectively…

The Best Selection - Get Started with Us to Discuss Your Needs

Lacha Paratha and Green Scallion Pie Production Line

The crispy layers of parathas or scallion pancakes are craved by people. ANKO's Lacha Paratha & Green Scallion Pie Production Line can produce parathas and scallion pancakes with extremely thin layers because it features a dough stretching device, which can stretch dough into a 0.8 mm thin sheet. By simply putting dough, scallions, and oil, the Lacha Paratha & Green Scallion Pie Production Line can mass-produce Chinese pancakes, scallion pancakes, and parathas automatically. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More Info Compare searies machineCompare with Similar Models

| Model no | Lacha Paratha and Green Scallion Pie Production Line LAP-5000 | Automatic Layer & Stuffed Paratha Production Line LP-3001 | Automatic Filming and Pressing Machine PP-2 Series |

|---|---|---|---|

| Description | More efficient dough feeder | Special structure can make dough balls with up to 32 layers | The thickness and size of product can be adjusted as required |

| Capacity | 2,100 - 6,300 pcs/hr | 3,000 pcs/hr | 1,500 pcs/hr |

| Weight | 50 - 130 g/pc | 40 - 130 g/pc | - |

| More Info | More Info | More Info |

Specifications

Capacity: 6,300 pcs/hr

Features

- Voltage can be designated.

- The thickness of lacha paratha wrapper and the amount of filling can be adjusted by parameter setting.

- The shape of lacha paratha can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

Suitable for

-

Central kitchena place where a large amount of food is prepared and cooked, where the dishes are served at mealtimes or processed into read-to-heat meals and where the operator should pay attention to food safety.

-

Food factorya building where machines are equipped to prepare ingredients and make, cook and package food. E.g. frozen food factory, ready meal factory.

-

Kitchen design and equipment suppliera person or organization that provides production process planning, commercial kitchen appliance, and food making machines.

-

Machine distributora person or organization that buys great food machines and sells them to local customers.

-

Entrepreneur who wants to invest in the food industrysomeone who starts a new food business and needs a comprehensive solution, including consulting service in equipment purchase and manufacturing know-how.

-

Cloud kitchena place where a large amount of food is prepared and cooked for takeout and delivery.

-

Restaurant/Cafeteriait refers to restaurants/cafeterias that need to switch manual to automatic production, in order to save time and labor and increase capacity.

-

Hotela place where food is cooked and served to more than a hundred of people at mealtime or processed dishes into ready-to-heat meals to sell.

-

Schoolit refers to school caterers who serve lunch to teachers, students, and staff or a central kitchen shared by several schools.

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- Downloads

- Best Selling

- Related Food Solutions Type